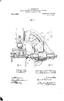

(2%22a. 2%. 4é. c2ate. 4-u-C MACHINE FOR FORMING GR00VES OR FLUTES IN TWIST DRILLS AND THE LIKE, H. WRIGHT, / M W AM 7-0 y :

|

|

|

- Garry Robinson

- 5 years ago

- Views:

Transcription

1 H. WRIGHT, MACHINE FOR FORMING GR00VES OR FLUTES IN TWIST DRILLS AND THE LIKE, APPLICATION FLED AUG, 4, 1917, 1,846,928. Patented July 20, SheeTS-SHEET 1. c2ate / M W AM 7-0 y : w (2%22a - 4-u-C 2%. 4é CN w

2 , H. WRIGHT, MACHINE FOR FORMING GROOVES OR FLUTES IN TWIST DRILLS AND THE LIKE, APPLICATION FILED AUG, 4, ,346,928. Patented July 20, SHEETS-She 2.

3 , H, WRIGHT, MACHINE FOR FORMING GR00VES OR FLUTES IN Twist DRILLS AND THE LIKE, APPLICATION FLED AG, 4, 1917, 1,346,928, Patented July 20, SHEETS-SHEET 3. l s ls s s s: 9. ZYZoe/2Zor: a 77-y

4 , H, WRGHT, MACHINE FOR FORMING GROOVES OR FLUTES IN T WIST DRILLS AND THE LIKE, APPCATION FED AUG, 4, 1917, 1,346,928, Patented July 20, SHEETS-SHEET 4. III I tra wwww. x Af Invezzor: o%ate 4enz W2. As

5 , H, WRIGHT, MACHINE FOR FORMING GROOVES OR FLUTES IN TWST DRILLS AND THE LIKE APPLICAON FLED AUG, 4, 1917, 1,346,928. Patented July 20, SHEETS-SHEET 5,

6 UNITED STATES PATENT OFFICE. ISAAC HENRY WRIGHT, OF MANCHESTER, ENGLAND, ASSIGNOR. To SMITH & coven TRY LIMITED, OF VIANCHESTER, ENGLAND. IMACHINE FOR FORMING GROOVES OR FIUTES IN TWIST-DRILLS AND THE LIKE. 1,346,92S. To all thorn, it may concern. l3e it known that I, IsAAC HENRY WRIGHT, a subject of the King of Great Britain, re siding at Gresley Iron Works, Ordsal Lane, Salford, Manchester, in the county of Lan caster, England, have invented new and use ful improvements in Machines for Forming the Grooves or Flutes in Twist-Drills and the like, of which the following is a specifi cation. w This invention relates to improvements in machines for forming the grooves or flutes in twist drills and the like. Specification of Letters Patent, The improved machine comprises three principal mechanisms, namely, first, the cut ting mechanism with an adjustable cutter head arranged to be swiveled to vary and regulate the width of the groove or flute and to be raised or lowered to vary the depth of the same. Secondly, the chuck or work carrying mechanism which holds the drill blanks (or other work) and presents them successively to the cutter or cutters by means of a conical turret movable about an axis oblique to the work axis of the machine and controlled by an indexing apparatus to de termine the number of grooves or flutes to be formed in the work. Thirdly, the traversing mechanism by which the chuck is alternately advanced toward and withdrawn from the cutter head while suitable angular movements are im parted to the chuck to produce the required spiral in the grooves or flutes by means of a bevel and clutch reversing gear and slow traverse worm gear with clutch and internal ratchet mechanism of which a sliding nut connected to levers in the cutter carrying mechanism forms a distinguishing feature. illustrate my improved machine on the accompanying drawings in which iigure 1 is a front view. Fig. 2 is a plan. Fig. 3 an elevation of the cutting end and iig. 4 an elevation of the other end showing the traverse regulating mechanism of th machine.... Fig. 5 is a detail view of the internal con struction of the worm wheel and ratchet. iig. 6 is a detail view of the spindle head, index spring plunger and inclined stop. Fig. 7 is a detail view of the device for changing the traverse from quick advance to cutting feed.... lg. 8 is a sectional plan of the clutches and ratchet for traverse regulation and Figs. 9 and 9 are details of w Patented July 20, Application filed August 4, Serial No. 184,465. mechanism for swiveling the cutter to vary the width of groove cut on the twist drill. Figs. 10 to 14 are detail views of the es capement mechanism. Figs. 10, 11 and 14 showing the relative position of the parts 60 during the cutting stroke and Higs. 12 and 13 the relative position of the parts during the return stroke. In carrying my invention into effect I em ploy a cutter C or cutters of suitable contour 65 mounted in the well known manner in the Spindle 115 (Fig. 3) which is rotated by belt (not shown) and pulley 11 or by gearing in its bearing in the cutter head 4. This cutter head 4 is arranged to swivel about a verti 70 cal Spindle 122, the axis of which intersects the axis of the cutter spindle 115 and also the axis of the drill blank D or other work to be fluted the blank passing through a suit able guide 28. To regulate the depth of the 75 groove or flute the cutter head is vertically adjustable upon its spindle 122 being raised by handles 80 rotating a worm gear 29 and sleeve 124 and screw 125. The upward pull of the driving belt (not shown) on the driv 80 ing pulley 11 is resisted by a strong spring 129 or springs bearing downward on the lower limb of the cutter head or otherwise Suitably arranged. For the purpose of producing a variable 85 depth of groove or flute spiral cams 130 and 131 are introduced between the raising Screw and the cutter head, the cam portion 131 having secured to it a lever 12 which is : connected to the traverse mechanism by a 90 connecting rod 105, Fig. 2, the degree of movement being variable by moving a con nection block 108 along the lever In order that the cutter C may be lifted out of the groove during the return move 95 ment of the work a lever 14, Fig. 3, bears against its lower limb and is acted upon at the proper times by a cam 104 on a sleeve 40 on the constantly rotating cone shaft 69 which drives the traverse mechanism. The time of operation of the cam is regulated by the traversing movement as hereinafter de scribed..... The drill blank D or other piece to be grooved or fluted is held in a simple spring chuck indicated by the numerals 150, 152 and 160, Fig. 1, attached by a bayonet joint to the conical turret 147 which carries an odd number of such chucks when the number of flutes required is even, or an even number of

7 chucks when the number of flutes required is odd. The conical turret 147 is arranged to rotate about an oblique axis 147 intersect ing the main axis of the drill blank D and its spindle 72 the chucks being so located in the turret that they can be brought exactly in line with the work spindle 72 and there located by a spring and ball plunger. The inclined turret axis is formed upon a revolv ing head 143 to which is rigidly fixed a cup 142 these parts being mounted and free to rotate upon the spindle head 141 which is keyed rigidly upon the work spindle 72 of the machine. Relative rotation between the chuck and the Work spindle T2 is prevented by a spring plunger 146 in the spindle head 141, Figs. 1 and 6, the plunger 146 engaging with suit able notches in the inner surface of the cup 142. When it is desired to index the drill blank D to be fluted this spring plunger 146 is caused to recede into the spindle head 141 by the action of a pin 145 the outward projecting end of which at the proper time engages the inclined surface of a stop 170, Fig. 6, with the result that the spindle 72 and work head 141 are disconnected from the chuck carrying members and may con tinue their revolution until the plunger 146 engages the next notch, the number of notches corresponding with the number of. flutes to be cut in the Work. This action is always arranged to occur at the end of the return traverse and the. reversal is carefully timed to agree with the instant when the plunger 146 engages 1,346,928 cylindrical spindle 72 upon one end of which is fixed the chuck mechanism previ ously described. A continuation of this spindle at the other end is in the form of a screw whose pitch is the same as the spiral E. of the groove or flute to be formed. This spindle is car ried in a plain cylindrical bearing 8 on the plain part and a nut bearing 20 on the Screwed part. The spindle 72 is rotated in either direc tion by a spur gear 44 keyed upon it and engaging with a wide faced spur gear 35 ar ranged as hereinafter described. When the spindle 72 is rotated in the forward direc tion the chuck mechanism and the work carried by it are advanced under the cutter C with a correct spiral movement as gov erned by the screw 72 and nut 20. Move ment in the reverse direction withdraws the work from the cutter. C. The wide faced spur wheel 35 is driven by a gear 43 keyed upon a shaft 70, reversals and variation of 25 speed of which are effected as follows:-- Power from the overhead driving appara 9ty tus or countershaft is received by step cone 5, Fig. 1, which is keyed upon a shaft, 69. carrying also a gear 41 engaging another gear 42 which, though keyed permanently. 30 to a bevel wheel 46 runs loosely upon its 95 shaft 70. This bevel wheel 46 is connected to a second bevel wheel 45 by an interme diate bevel wheel 50 forming a reversing mechanism of well known form. The shaft may be connected to either of the bevel with the notch. During this relative rota wheels by a sliding clutch 47 engaging cor tion, the chuck carrying portion is prevent responding clutches on the parallel bevel wheels 46 or 45. ed from rotating by a pin 171 resting on the The intermediate bevel. 40 stop 170 mounted upon a spring 172 to allow wheel 50 is used as a starting point for a for any slight irregularity of the timing of train of gears 48, 49, 48, (Fig. 2) arranged 05 reversal. This relative rotating of the spin to give motion to a worm 58 (Fig. 4) en gaging a worm wheel 30. The considerably dle head 141 and the chuck carrying head is caused also to rotate the conical member reduced speed at which the worm wheel carrying the chucks in the following rotates is designed to suit the actual cut or other suitable manner:- ting advance of the drill blank D or work. O The conical member 147 has a number of The internal construction of the worm projecting pins 173, Fig. 1, serving as rudi wheel 30, as clearly indicated in the detail mentary teeth by which it may be rotated on view, Fig. 5, is such that its outer portion 50 its oblique axis and these teeth intercept which engages the worm 58 is connected the path of pins 14S in the spindle head 141. to the center ratchet portion 52 by a rock 15 While the spindle head and chuck body are ing ratchet pawl 54 to insure correct en rotating together no inter-action occurs be gagement of which a friction spring 53 is tween these two series of pins but when the placed in a groove in the wheel engaging 55 plunger 146 is depressed and relative ro pins on the ratchet pawl 54. This ratchet tation occurs the pins 148 in the spindle mechanism is designed to drive the center 20 head act on the pins 173 in the conical tur portion in the feeding direction of the trav ret. During the fraction of revolution be erse and by reason of the ratchet it does this fore the plunger 146 again engages, the pins only when the clutch 47 is disengaged from have turned the conical turret 147 to the bevel wheels 46 and 45. If the clutch 47 its next position and brought a fresh drill be engaged to drive the traverse mechanism 125 in the same direction as the ratchet would blank D in line with the work spindle and ready for advancing to the cutting mech drive it the shaft and center 52 of the ratchet anism. wheel over-runs the pawl 54 and advances the 65 The traversing mechanism consists of the drill blank D at the quick rate. In order that the drill blank or work may be withdrawn

8 1,346,928 by revolving in the opposite direction the fined between a stud 64 on the frame and ratchet wheel can be disconnected from the a stud on a lever 16 which has a V shaped shaft by a clutch 51 both clutches 47 and striking face 65 in contact with a similar 51 being operated by fingers or projections striking face 66 on one arm of the bell 80y upon a slide bar 80, Fig. 8. crank lever 15. At the other extreme of 70 By suitable location of the clutch 54, the travel the pin 19 and link 19 are elevated operating finger 80 on the slide bar 80 and by a fixed pin in the spiral groove engaging a suitable degree of lost motion between the the pin 19* and causing the reverse order clutch and its operating finger the slide of these movements thus engaging the O bar 80 may move a sufficient distance to dis clutch 47 with the bevel gear 45 and the 75 engage the clutch 47 from its bevel wheel clutch 51 with the ratchet center while still allowing the other clutch 51 The reversing mechanism so far described to engage the ratchet center 52 of the Worm deals only with the definite reversal at each wheel 30. Further movement of the slide extreme of the travel, the intermediate 5 bar 80 withdraws the latter clutch 51 and change which occurs when the fast forward 80, totally disconnects the Worm wheel 30 after travel is changed to the slow travel for the which it engages the other clutch 47 with cutting operation is effected as follows:- the other bevel wheel 46 for the quick re At the moment preceding contact of the turn traverse of the work. From this it work with the cutter C, a collar 63, Figs. 20 will be understood that while the clutch 47 1 and 7, on the work spindle 72 rides over 85 engages one bevel wheel 45 the work is ad a projecting lever 99 the lower arm of which vancing rapidly toward the cutter C just bears upon the pin 82 on the sliding bar 80 - before reaching which the slide bar 80 is and, moving this to the right an amount operated to disconnect this clutch 47 from sufficient to disengage the bevel wheel clutch 90 its bevel wheel 45 leaving the other clutch 47 from the fast forward bevel 45, leaves the 51 in engagement with the ratchet center 52. motion to be continued during cutting by The slow moving worm gear 30 then takes the slow moving worm wheel 30 acting up the continuation of the movement by through its ratchet. It will be understood means of its ratchet mechanism, 52, 54, and that the collar 63 can be set at any suitable 30 feeds the work slowly under the cutter C. position along the screwed portion of the 95 On completing the length of groove or flute work spindle 72 and also that during its ac required in the work the slide bar 80 is tion on the lever it is acting against the moved still farther to the right when the load and fire mechanism but the amount clutch 51 is withdrawn from the ratchet of this motion is not sufficient to trip the 35 wheel 52 and the other clutch 47 is engaged same and cause complete reversal. The stop 100 with the opposite bevel wheel 46 which, member 98 connected to the stop cylinder running in the opposite direction, quickly 97 is the one whose setting determines the returns the work spindle 72 to the starting closeness with which the work spindle 72 ap position. proaches the cutter C. and this setting is 40 The limits of travel of the work spindle regulated by the length of the work and of are defined by adjustable projections upon the grooves or flutes to be cut. a cylinder 97, Fig. 2, or equivalent secured To vary the speed at which the work upon the same shaft as the wide faced gear travels under the cutter C the train of 35 which drives the work spindle 72. In wheels 48, 49, 48, from the intermediate 45. this cylinder 97 is cut a deep spiral groove in bevel wheel 50 may be replaced with other 0. which engages the pin 19 on the end of a suitable wheels.. connecting link 19. To bring the travel mechanism to rest at By a suitable arrangement of the stop any moment desired the slide bar 80 is members 98, 13, a suitable number of rev fitted with a V block 83 adjacent to which 50 olutions of the cylinder 97 may occur before is a plunger 85 having a suitably formed end 115 the link 19 comes in reach of the stop mem to engage the V block. When the plunger ber 98 which is revolving with the cylinder. 85 is pushed into the V, block 83 it moves When, finally, this stop 98 makes contact the slide bar 80 into a position in which all with the link 19, it depresses the same and clutches are disengaged and in so doing it gives motion to a bell crank lever 15 the overcomes the spring 114 of the load and other member of which engages the slide fire mechanism previously described. bar 80 by a pin 82, Figs. T and 8. The po To re-start the mechanism the plunger 85 sition of this lever 15 is also controlled by is withdrawn when the spring 114 of the a trip spring 114 of well known form, load and fire mechanism re-asserts itself 60 known as the load and fire' mechanism, and returns the clutches to the positions 125 and which avoids the possibility of the which they held before the plunger was mechanism stopping when half reversed and used. - insures that reversing, once commenced Certain movements of the head 4 for shall be completed. As shown in Figs. 1 carrying the cutting mechanism, viz. the 65 and 7, the trip spring 114 is coiled and con raising of the cutter C to give decreased. 30

9 1346,928 the cutting position of the cutter head 4 depth of groove and the swiveling of the cutter to give increased width of groove are during the the cutting stroke as illustrated obtained by connection to the traverse mechanism in the following manner:- by Figs. 10, 11 and 14, and the raised posi The shaft 70 carrying the reverse mecha tion of the cutter head on the return stroke as illustrated by Figs. 12. and 13. nism and subject to the action of the same 70 On the sleeve 40 is fixed a disk with two has a continuation 78, Figs. 1 and 2, in the projections or pins 90, 90, diametrically op form of a screw. A slide bar 79 (Fig. 9) posite...but in different planes. Near this adjacent and parallel to the screw 78, carries 10 a slide nut 31, which thus has a movement disk is the detent lever 17 which is adapted to engage one or other of the two pins 90, 75 proportional to the movement of the work 90, being moved into such engagement by held in the chuck as to both revolution and the slide bar 80 to which it is loosely con advance and return. On the upper face nected of this nut 31 is attached the connecting rod When the pin 90 is engaged with the de 15 or link, 105 referred to in connection with tent lever 17 the lever 14 is uninfluenced the lever 12, and the other end of this link is attached to the connecting block or by the cam 104 which is held from rotation and the cutter head 4 is allowed to rest in adjustable clamp 108 on the lever 12 which its lowest position while a groove is being is fixed upon the cam member 131, Fig. 3, cut in the blank D. When the slide bar 80 20, which by means of the corresponding cam acting on the detent lever 17 releases the pin controls the vertical position of the 90 the sleeve. 40 makes half a revolution cutter head 4. To the lower face of the nut 31 may be attached a connecting link until the pin 90 engages the detent lever 17 meanwhile the cam. 104 in its half revolu 180, see Figs. 9 and 9. Connected to the tion depresses the lever 14 and raises the 25 free end of the link 180 is one end of link cutter head 4 so that the work travels back , the opposite end of the latter being clear of the cutter C during the return slotted and rigidly connected to the head 4 stroke.. by a bolt 181 which passes through the slot and permits adjustment of the link 180 What I claim as my invention and desire to secure by Letters Patent of the United upon the head when the bolt is loosened. States is: This adjustable connection is such that the 1. A machine for making twist drills com actions of the nut 31 is to swivel the cutter. prising a work carrying mechanism includ head 4 about its vertical axis 122 passing ing a work spindle, a turret rotatably through the cutter C and the work D, the mounted upon said spindle on an axis which 35. amount of this swivel action during the is oblique to the axis of said spindle, a plu 100 travel of the work being adjusted to give the required widening of the groove or flute rality of work holding members mounted on said turret, a cutter, said turret being adapt to be formed. The cutter head 4 is subject ed to rotate during the cutting operation of to a further movement which raises the the drills, means for automatically moving 40 cutter C clear of the work during the re said turret about the Work spindle to suc 105 turn travel with a view to avoid marking cessively present the surfaces for grooves in the finished surface. This motion is ob tained from the cone shaft 69 in the follow each drill to the cutter, and means for auto matically moving the turret about its ob ing manner:- lique axis for presenting The cone shaft 69 passes through the successive pieces of Work to the cutter. sleeve 40 which is frictionally connected to the shaft by a slipping clutch 68 adjusted 2. A machine for making twist drills com 10 by a spring 113 and lock nuts 58. Upon prising a cutter, a work carrier, and means. for moving the work carrier toward and this sleeve 40 is fixed the cam 104 which en 50 away from said cutter, comprising a screw gages one arm of the bell crank lever 14 the other arm bearing on the bottom surface of threaded shaft, mechanism for reversing 115 the direction of movement of said shaft, the cutter head 4 in such a way that the high side of the cam 104 acts on the lever and means for retarding the movement of 14 thereby elevating the cutter head 4 an said shaft comprising a worm gear inter posed between the mechanism and said 55 amount sufficient to lift the cutter C clear of shaft, an internal pawl and rachet connec 120 the work D. The times of this action are controlled by an escapement on the sleeve tion between said shaft and worm gear, and 40 the pawl or detent lever 17 of which is a clutch operating member having means for causing lost motion, said member opera fulcrumed on a stud 17 and is connected to tively connecting the worm gear and shaft. 60. the slide bar 80 of the reverse mechanism. This escapement, which is illustrated by 3. A machine for making twist drills com 125 prising a work carrying mechanism includ the detail views, Figs. 10 to 14, is arranged ing a work spindle, a turret rotatably to allow half a revolution of the sleeve 40 and mounted upon said spindle on an axis cam 104 at each reversal of the machine the 65 two positions of the cam corresponding with which is oblique to the axis of said spindle, a plurality of work holding members mount 130

10 O 1,346,928 ed on said turret, a cutter, said turret be ing adapted to rotate during the cutting operation of the drills, means for auto matically moving said turret about the work spindle to successively present the surfaces for grooves in each drill to the cutter, a cut ter head for said cutter mounted for move ment in horizontal and vertical planes, means for actuating said cutter head where by said cutter will be caused to cut grooves in the work, varying in width and depth, and means for moving said mechanism toward and away from said cutter in such manner that said mechanism will be fed for a major portion of the distance toward said 15 cutter at a speed exceeding the speed at which it is fed for the remainder of the distance toward said cutter and for moving the mechanism away from the work at a quick speed. 20 In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses. ISAAC HENRY WRIGHT. Witnesses: S. W. GILLETT, HERBERT RowIAND ABBEY. 5.

July 21, J. W. BATE 1,815,885 SCREW JACK

July 21, 1931. J. W. BATE 1,81,88 Filed Jan. 3, 1927 of 77 Zzz, II -2. 72 Sim r Mr.SIN 4. N 4. & NISINSYN2 72 SS 16 y2) W 7. Šá N 2. Sheets-Sheet l 3 A. % 76 --------- % % 3. W 2 m % % 3. - - - --------

July 21, 1931. J. W. BATE 1,81,88 Filed Jan. 3, 1927 of 77 Zzz, II -2. 72 Sim r Mr.SIN 4. N 4. & NISINSYN2 72 SS 16 y2) W 7. Šá N 2. Sheets-Sheet l 3 A. % 76 --------- % % 3. W 2 m % % 3. - - - --------

A. J. BRADLEY. No. 781,124, Witnesses. r Inventor:2.É.-2, PATENTED JAN, 31, 1905, 47-acre. By C2. 6.P 7 &nd) Attorneys, DRAFTSMAN's PRINTING MACHINE,

No. 781,124, A. J. BRADLEY. DRAFTSMAN's PRINTING MACHINE, APPLICATION FILED NOW, 10, 1903, PATENTED JAN, 31, 1905, 2 SHEETS-SHEET l. 2 V 2 Harare none r 3e3 SS ser-re SNSSNSEN A. - es Witnesses. r Inventor:2.É.-2,

No. 781,124, A. J. BRADLEY. DRAFTSMAN's PRINTING MACHINE, APPLICATION FILED NOW, 10, 1903, PATENTED JAN, 31, 1905, 2 SHEETS-SHEET l. 2 V 2 Harare none r 3e3 SS ser-re SNSSNSEN A. - es Witnesses. r Inventor:2.É.-2,

No. 394,668, Patented Dec. 18, 1888.

(No Model.) 3 Sheets-Sheet 1. H. S. S. WAT KIN. ANEROID BAROMETER, No. 394,668, Patented Dec. 18, 1888. u D. L. E. 5. N. perers, Photo-lithographer, Washington, D.C. No Model.) No. 394,668 3 Sheets-Sheet

(No Model.) 3 Sheets-Sheet 1. H. S. S. WAT KIN. ANEROID BAROMETER, No. 394,668, Patented Dec. 18, 1888. u D. L. E. 5. N. perers, Photo-lithographer, Washington, D.C. No Model.) No. 394,668 3 Sheets-Sheet

4/ /hoe 2eceolónzee-zee-ee. E 6 Ée, S. 2&772zz, z/7%zz. J422/s, Feb. 22, s. MANDL 2,108,866. Avezzr. Filed April 17, Sheets-Sheet l. 2.

Feb. 22, 1938. s. MANDL SOCKET WRENCH Filed April 17, 1936 2 Sheets-Sheet l. Se E 6 Ée, S. 2.72 N NS s Na w Avezzr. 2&772zz, z/7%zz 4/ /hoe 2eceolónzee-zee-ee J422/s, Feb. 22, 1938. S. MAND SOCKET WRENCH

Feb. 22, 1938. s. MANDL SOCKET WRENCH Filed April 17, 1936 2 Sheets-Sheet l. Se E 6 Ée, S. 2.72 N NS s Na w Avezzr. 2&772zz, z/7%zz 4/ /hoe 2eceolónzee-zee-ee J422/s, Feb. 22, 1938. S. MAND SOCKET WRENCH

No. 622,774. Patented Apr. 1, 1899.

No. 622,774. Patented Apr. 1, 1899. J. M. MACLUCH. METHOD OF MANUFACTURING INDIA RUBBER OR OTHER ENDLESS BANDS OR STRIPS. (Application filed Oct. 4, 1898. (No Model.) 3 Sheets-Sheet 1. tenorris Peters

No. 622,774. Patented Apr. 1, 1899. J. M. MACLUCH. METHOD OF MANUFACTURING INDIA RUBBER OR OTHER ENDLESS BANDS OR STRIPS. (Application filed Oct. 4, 1898. (No Model.) 3 Sheets-Sheet 1. tenorris Peters

A, L, LOOMS,???, APPLICAT 10N Fi ED 3 ULY

A, L, LOOMS,???, APPLICAT 10N Fi ED 3 ULY 22 91 5.,-----------------------------------------------------------=----------=--------------?-?-----------??------------------------------------------------------------??

A, L, LOOMS,???, APPLICAT 10N Fi ED 3 ULY 22 91 5.,-----------------------------------------------------------=----------=--------------?-?-----------??------------------------------------------------------------??

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE. . _ LAWN MOWER. N0.'554,081. Patented Feb. 4, $5 9; Em ;! \ g/ F

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE.. _ LAWN MOWER. N0.'554,081. Patented Feb. 4, 1896. H $5 9; Em ;! \ g/ F % (No Model.) E. W. MCGUIRE. LAWN MOWER. a" Sheets-Sheet 2, No. 554,081. PéJtentedI'eb.

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE.. _ LAWN MOWER. N0.'554,081. Patented Feb. 4, 1896. H $5 9; Em ;! \ g/ F % (No Model.) E. W. MCGUIRE. LAWN MOWER. a" Sheets-Sheet 2, No. 554,081. PéJtentedI'eb.

1,502, Boaz, only 22, MARIONETTE M. M. DONDO 27 A/ %- - IA WEATOR

only 22, 1924. t M. M. DONDO MARIONETTE Filed July 1, 1922 3. Sheets-Sheet l - IA WEATOR s alfull-.. 27 Boaz, 27 A/ %- Y.f iii).* d July 22, 1924 e M. M. DONDO MARIONETTE Filled July l, 1922 3 Sheets-Sheet

only 22, 1924. t M. M. DONDO MARIONETTE Filed July 1, 1922 3. Sheets-Sheet l - IA WEATOR s alfull-.. 27 Boaz, 27 A/ %- Y.f iii).* d July 22, 1924 e M. M. DONDO MARIONETTE Filled July l, 1922 3 Sheets-Sheet

Nov. 14, 1967 D. PREston 3,352,553 CONTINUOUS FORMS FOLDER MACHINE

Nov. 14, 1967 D. PREston CONTINUOUS FORMS FOLDER MACHINE Filed Oct. 14, 1965 4 Sheets-Sheet Nov. 14, 1967 D. PRESTON CONTINUOUS FORMS FOLDER MACHINE Filed Oct. l4, 1965 4. Sheets-Sheet 2 t -O.S. s t ae

Nov. 14, 1967 D. PREston CONTINUOUS FORMS FOLDER MACHINE Filed Oct. 14, 1965 4 Sheets-Sheet Nov. 14, 1967 D. PRESTON CONTINUOUS FORMS FOLDER MACHINE Filed Oct. l4, 1965 4. Sheets-Sheet 2 t -O.S. s t ae

Drilling. Drilling is the operation of producing circular hole in the work-piece by using a rotating cutter called DRILL.

Drilling Drilling is the operation of producing circular hole in the work-piece by using a rotating cutter called DRILL. The machine used for drilling is called drilling machine. The drilling operation

Drilling Drilling is the operation of producing circular hole in the work-piece by using a rotating cutter called DRILL. The machine used for drilling is called drilling machine. The drilling operation

PREVIEW COPY. Table of Contents. Lesson One Using the Dividing Head...3. Lesson Two Dividing Head Setup Lesson Three Milling Spur Gears...

Table of Contents Lesson One Using the Dividing Head...3 Lesson Two Dividing Head Setup...19 Lesson Three Milling Spur Gears...33 Lesson Four Helical Milling...49 Lesson Five Milling Cams...65 Copyright

Table of Contents Lesson One Using the Dividing Head...3 Lesson Two Dividing Head Setup...19 Lesson Three Milling Spur Gears...33 Lesson Four Helical Milling...49 Lesson Five Milling Cams...65 Copyright

United States Patent 19 Couture et al.

United States Patent 19 Couture et al. 54 VEGETABLE PEELINGAPPARATUS 76 Inventors: Fernand Couture; René Allard, both of 2350 Edouard-Montpetit Blvd., Montreal, Quebec, Canada, H3T 1J4 21 Appl. No.: 805,985

United States Patent 19 Couture et al. 54 VEGETABLE PEELINGAPPARATUS 76 Inventors: Fernand Couture; René Allard, both of 2350 Edouard-Montpetit Blvd., Montreal, Quebec, Canada, H3T 1J4 21 Appl. No.: 805,985

J. T. WHALEN, PERMUTATION PADLOCK, APPLICATION FILED JULY 14, 1908, 940, )evooocs: ????????

940,763. J. T. WHALEN, PERMUTATION PADLOCK, APPLICATION FILED JULY 14, 1908, S È?? 928)evooocs:???????? J. T. WHALEN,. PERMUTATION PADI,00K. APPLICATION FILED JULY 14, 1908,. 940,763. y, Patented Nov.

940,763. J. T. WHALEN, PERMUTATION PADLOCK, APPLICATION FILED JULY 14, 1908, S È?? 928)evooocs:???????? J. T. WHALEN,. PERMUTATION PADI,00K. APPLICATION FILED JULY 14, 1908,. 940,763. y, Patented Nov.

Seal. e/ IOI - N3ssersys (RH S. O. CZazazzee c1722. May 14, c. J. Rio 2,200,896 HOIST PULLEY AND ROPE GRIPPER.

May 14, 19. c. J. Rio 2,0,896 HOIST PULLEY AND ROPE GRIPPER Filed Sept. 13, 1939 2 Sheets-Sheet l S. SAYS SaN7 IOI - N3ssersys (RH S. O A 7477 NSSK A ZOA to R3N Seal S YaYaas 4. S A- Z-A-Z NYP 2 SARSSSYO

May 14, 19. c. J. Rio 2,0,896 HOIST PULLEY AND ROPE GRIPPER Filed Sept. 13, 1939 2 Sheets-Sheet l S. SAYS SaN7 IOI - N3ssersys (RH S. O A 7477 NSSK A ZOA to R3N Seal S YaYaas 4. S A- Z-A-Z NYP 2 SARSSSYO

Summer Junior Fellowship Experience at LUMS. Maliha Manzoor 13 June 15 July, 2011 LUMS Summer Internship

Summer Junior Fellowship Experience at LUMS Maliha Manzoor 13 June 15 July, 2011 LUMS Summer Internship Internship Schedule June 13-17: 2D and 3D drawings in AutoCAD June 20-24: 2D and 3D drawings in AutoCAD

Summer Junior Fellowship Experience at LUMS Maliha Manzoor 13 June 15 July, 2011 LUMS Summer Internship Internship Schedule June 13-17: 2D and 3D drawings in AutoCAD June 20-24: 2D and 3D drawings in AutoCAD

Dec. 15, W. A. MATHESON 1,836,981 MASSAGING AND EXERCISING APPARATUS. of7eavezza27. z0/z77es 5." 4-2/64/ (M26a77% Azazesozz 2421% /72%

Dec. 15, 1931. W. A. MATHESON 1,836,981 MASSAGING AND EXERCISING APPARATUS Filed Aug. 8, 1927 4. Sheets-Sheet z0/z77es 5." 4-2/64/ of7eavezza27 (M26a77% Azazesozz 2421% /72% Dec. 15, 1931. W. A. MATHESON

Dec. 15, 1931. W. A. MATHESON 1,836,981 MASSAGING AND EXERCISING APPARATUS Filed Aug. 8, 1927 4. Sheets-Sheet z0/z77es 5." 4-2/64/ of7eavezza27 (M26a77% Azazesozz 2421% /72% Dec. 15, 1931. W. A. MATHESON

United States Patent (19) Over et al.

United States Patent (19) Over et al. 54). CAPPING HEAD AND MACHINE 75) Inventors: David J. Over; Daniel J. Burkhardt, both of Richmond, Ind. 73) Assignee: Aluminum Company of America, Pittsburgh, Pa.

United States Patent (19) Over et al. 54). CAPPING HEAD AND MACHINE 75) Inventors: David J. Over; Daniel J. Burkhardt, both of Richmond, Ind. 73) Assignee: Aluminum Company of America, Pittsburgh, Pa.

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, (Applicatioxg filed Jan. 27, 1899.

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, 81.0. (Applicatioxg filed Jan. 27, 1899.) ' (No Model.) 2 s_heets-sheet l. ó» y@ gw/q. Nn. 635,225.. f Patentad

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, 81.0. (Applicatioxg filed Jan. 27, 1899.) ' (No Model.) 2 s_heets-sheet l. ó» y@ gw/q. Nn. 635,225.. f Patentad

United States Patent (19)

United States Patent (19) Negley 54 DRILL GRINDER 75) Inventor: Marvin C. Negley, Clarinda, Iowa 73) Assignee: Lisle Corporation, Clarinda, Iowa 22 Filed: Oct. 29, 1974 (21) Appl. No.: 518,757 (52) U.S.

United States Patent (19) Negley 54 DRILL GRINDER 75) Inventor: Marvin C. Negley, Clarinda, Iowa 73) Assignee: Lisle Corporation, Clarinda, Iowa 22 Filed: Oct. 29, 1974 (21) Appl. No.: 518,757 (52) U.S.

Lathes. CADD SPHERE Place for innovation Introduction

Lathes Introduction Lathe is one of the most versatile and widely used machine tools all over the world. It is commonly known as the mother of all other machine tool. The main function of a lathe is to

Lathes Introduction Lathe is one of the most versatile and widely used machine tools all over the world. It is commonly known as the mother of all other machine tool. The main function of a lathe is to

Z3: wa 2%ist a? 4,822. rizzesses 3.5L ES. K. N. 944,489. Patented Dec. 28, &ANN

- B, A, INDERMAN, EDCNG ATTACHMENT FOR LUMBER JOINING MACHINES, APPLICATION FILED JUNE 1, 1909. 944,489. Patented Dec. 28, 1909. 4. SHEETS-SHEET 1. E 26&ANN assa, 3.5L ES. K. N. Z3: 3. rizzesses f 2. aza

- B, A, INDERMAN, EDCNG ATTACHMENT FOR LUMBER JOINING MACHINES, APPLICATION FILED JUNE 1, 1909. 944,489. Patented Dec. 28, 1909. 4. SHEETS-SHEET 1. E 26&ANN assa, 3.5L ES. K. N. Z3: 3. rizzesses f 2. aza

ROOP LAL Unit-6 Lathe (Turning) Mechanical Engineering Department

Notes: Lathe (Turning) Basic Mechanical Engineering (Part B) 1 Introduction: In previous Lecture 2, we have seen that with the help of forging and casting processes, we can manufacture machine parts of

Notes: Lathe (Turning) Basic Mechanical Engineering (Part B) 1 Introduction: In previous Lecture 2, we have seen that with the help of forging and casting processes, we can manufacture machine parts of

MANUFACTURING TECHNOLOGY

MANUFACTURING TECHNOLOGY UNIT V Machine Tools Milling cutters Classification of milling cutters according to their design HSS cutters: Many cutters like end mills, slitting cutters, slab cutters, angular

MANUFACTURING TECHNOLOGY UNIT V Machine Tools Milling cutters Classification of milling cutters according to their design HSS cutters: Many cutters like end mills, slitting cutters, slab cutters, angular

(No Model.) 2. Sheets-Sheet 1.

(No Model.) 2. Sheets-Sheet 1. D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS, No. 429,629, Patented June 10, 1890. (No Model.) 2. Sheets-Sheet 2, D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS. No. 429,629,

(No Model.) 2. Sheets-Sheet 1. D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS, No. 429,629, Patented June 10, 1890. (No Model.) 2. Sheets-Sheet 2, D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS. No. 429,629,

(No Model.) 8. Sheets-Sheet,, H. D., MENTZEL, MECHANICAL MOVEMENT, No. 447,964, Patented Mar, 10, 1891, (. ) 8-line K22,

(No Model.) 8. Sheets-Sheet,, H. D., MENTZEL, MECHANICAL MOVEMENT, No. 447,964, Patented Mar, 10, 1891, ry (. ) 8-line h -VV TNESSES - INN/ENT OR K22, 2.2 2.2. /-9a/ 34 - a (No Mode.) 8 Sheets-Sheet 2.

(No Model.) 8. Sheets-Sheet,, H. D., MENTZEL, MECHANICAL MOVEMENT, No. 447,964, Patented Mar, 10, 1891, ry (. ) 8-line h -VV TNESSES - INN/ENT OR K22, 2.2 2.2. /-9a/ 34 - a (No Mode.) 8 Sheets-Sheet 2.

SERIES I MILLING MACHINES

INSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES TP5260 Revised: August 29, 2005 Manual No. M-450 Litho in U.S.A. Part No. M -0009500-0450 June, 2003 MAINTENANCE PROCEDURES

INSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES TP5260 Revised: August 29, 2005 Manual No. M-450 Litho in U.S.A. Part No. M -0009500-0450 June, 2003 MAINTENANCE PROCEDURES

Ahsanullah University of Science and Technology (AUST) Department of Mechanical and Production Engineering

Ahsanullah University of Science and Technology (AUST) Department of Mechanical and Production Engineering LABORATORY MANUAL For the students of Department of Mechanical and Production Engineering 1 st

Ahsanullah University of Science and Technology (AUST) Department of Mechanical and Production Engineering LABORATORY MANUAL For the students of Department of Mechanical and Production Engineering 1 st

J. H. BOURGON WINDOW REGULATOR INVENTOR. VO5AA/ AyasoA6GO/y

Feb. 8, 1927. J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 Sheets-Sheet l INVENTOR VO5AA/ AyasoA6GO/y BY Ed Feb. 8, 1927.... J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 2 Sheets-Sheet 2 N

Feb. 8, 1927. J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 Sheets-Sheet l INVENTOR VO5AA/ AyasoA6GO/y BY Ed Feb. 8, 1927.... J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 2 Sheets-Sheet 2 N

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION PREPARATION FOR OPERATION CAUTIONS ON USE OPERATION

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION ------------------------------------- 1 PREPARATION FOR OPERATION 1. Adjustment of needle bar stop position ---------------------------------------------------------

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION ------------------------------------- 1 PREPARATION FOR OPERATION 1. Adjustment of needle bar stop position ---------------------------------------------------------

April 1, ,488,659 J. C. ABEL ET AL WALK OVER SEAT. fill. É 2 N N PPAP //W/AW7OAS. casez/24/7zee. a 774 A2Z2 A/2//av/22/ a 77OAMAY

April 1, 1924. 1,488,659 fill. WALK OVER SEAT PS3 Feb: 5. 1921 3. Sheets-Sheet l É 2 a e s 2 10 N N PPAP 2 //W/AW7OAS casez/24/7zee a 774 A2Z2 A/2//av/22/ a 77OAMAY April 1, 1924. WALK OWER SEAT Filed

April 1, 1924. 1,488,659 fill. WALK OVER SEAT PS3 Feb: 5. 1921 3. Sheets-Sheet l É 2 a e s 2 10 N N PPAP 2 //W/AW7OAS casez/24/7zee a 774 A2Z2 A/2//av/22/ a 77OAMAY April 1, 1924. WALK OWER SEAT Filed

LANDMARK UNIVERSITY, OMU-ARAN

LANDMARK UNIVERSITY, OMU-ARAN LECTURE NOTE: DRILLING. COLLEGE: COLLEGE OF SCIENCE AND ENGINEERING DEPARTMENT: MECHANICAL ENGINEERING PROGRAMME: MECHANICAL ENGINEERING ENGR. ALIYU, S.J Course code: MCE

LANDMARK UNIVERSITY, OMU-ARAN LECTURE NOTE: DRILLING. COLLEGE: COLLEGE OF SCIENCE AND ENGINEERING DEPARTMENT: MECHANICAL ENGINEERING PROGRAMME: MECHANICAL ENGINEERING ENGR. ALIYU, S.J Course code: MCE

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0185581 A1 Xing et al. US 2011 0185581A1 (43) Pub. Date: Aug. 4, 2011 (54) COMPACT CIRCULAR SAW (75) (73) (21) (22) (30) Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0185581 A1 Xing et al. US 2011 0185581A1 (43) Pub. Date: Aug. 4, 2011 (54) COMPACT CIRCULAR SAW (75) (73) (21) (22) (30) Inventors:

Nov. 18, S. P. Rockwell HARDNESS TESTING MACHINE 1, Filed Sept. 2 Sheets-Sheet II. lill, INVENTOR.

Nov. 18, 1924. S. P. Rockwell HARDNESS TESTING MACHINE Filed Sept. lill, 199 1,16.7 2 Sheets-Sheet II INVENTOR. Nov. 8, 1924. 1,16,7 S, FP, ROCKWELL HARDNESS TESTING MACHINE Filed Sept. 1, 1919 2 Sheets-Sheet

Nov. 18, 1924. S. P. Rockwell HARDNESS TESTING MACHINE Filed Sept. lill, 199 1,16.7 2 Sheets-Sheet II INVENTOR. Nov. 8, 1924. 1,16,7 S, FP, ROCKWELL HARDNESS TESTING MACHINE Filed Sept. 1, 1919 2 Sheets-Sheet

1. The Lathe. 1.1 Introduction. 1.2 Main parts of a lathe

1. The Lathe 1.1 Introduction Lathe is considered as one of the oldest machine tools and is widely used in industries. It is called as mother of machine tools. It is said that the first screw cutting lathe

1. The Lathe 1.1 Introduction Lathe is considered as one of the oldest machine tools and is widely used in industries. It is called as mother of machine tools. It is said that the first screw cutting lathe

OPERATING INSTRUCTIONS 3421UX VETERANS BLVD, CARLSTADT, NJ 07072

OPERATING INSTRUCTIONS 3421UX5-1 400 VETERANS BLVD, CARLSTADT, NJ 07072 CONTENTS DESCRIPTION... 3 OPERATOR INFORMATION... 5-8 INSTALLATION...... 4 ADJUSTMENT... 8-17 LUBRICATION... 5 INDEX Description

OPERATING INSTRUCTIONS 3421UX5-1 400 VETERANS BLVD, CARLSTADT, NJ 07072 CONTENTS DESCRIPTION... 3 OPERATOR INFORMATION... 5-8 INSTALLATION...... 4 ADJUSTMENT... 8-17 LUBRICATION... 5 INDEX Description

TOP WORK ISO 9001.CE UNIVERSAL CUTTER & TOOL GRINDER

TOP WORK ISO 9001.CE UNIVERSAL CUTTER Precise ball groove of conformation Inclination of Wheelhead The wheelhead can easily tilt up to ±15 degrees, with a 360-degrees swivel on the horizontal plane. The

TOP WORK ISO 9001.CE UNIVERSAL CUTTER Precise ball groove of conformation Inclination of Wheelhead The wheelhead can easily tilt up to ±15 degrees, with a 360-degrees swivel on the horizontal plane. The

No. 752,792. PATENTED FEB, 23, 1904, H, MOYA, TYPE WRITING MACHINE, APPLICATION FLED JAN. 10, RO MODEL, 7 SHEETS-SHEET l. Zz 23 sir H.

No. 752,792. PATENTED FEB, 23, 1904, H, MOYA, TYPE WRITING MACHINE, APPLICATION FLED JAN. 10, 1902. RO MODEL, 7 SHEETS-SHEET l. Zz 23 sir H. - - - - - - - - M. ------------ 27 I r -----------------a -

No. 752,792. PATENTED FEB, 23, 1904, H, MOYA, TYPE WRITING MACHINE, APPLICATION FLED JAN. 10, 1902. RO MODEL, 7 SHEETS-SHEET l. Zz 23 sir H. - - - - - - - - M. ------------ 27 I r -----------------a -

zine plate 26 and support the partition plate flush with the bottoms of the chan

T R A N S F E R A N D D I S T R I B U T I N G M E C H A N I S M 2 8 5 loosen the lock nut and to turn the screw to set the channel entrance as described above. It will be noted that the screw is threaded

T R A N S F E R A N D D I S T R I B U T I N G M E C H A N I S M 2 8 5 loosen the lock nut and to turn the screw to set the channel entrance as described above. It will be noted that the screw is threaded

United States Patent (19) Onsrud

United States Patent (19) Onsrud 11) Patent Number: 45 Date of Patent: Aug. 27, 1985 (54) ROUTING MACHINES 76 Inventor: Charles R. Onsrud, P.O. Box 416, Troutman, N.C. 28166 21) Appl. No.: 415,012 22 Filed:

United States Patent (19) Onsrud 11) Patent Number: 45 Date of Patent: Aug. 27, 1985 (54) ROUTING MACHINES 76 Inventor: Charles R. Onsrud, P.O. Box 416, Troutman, N.C. 28166 21) Appl. No.: 415,012 22 Filed:

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 20120047754A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0047754 A1 Schmitt (43) Pub. Date: Mar. 1, 2012 (54) ELECTRICSHAVER (52) U.S. Cl.... 30/527 (57) ABSTRACT

US 20120047754A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0047754 A1 Schmitt (43) Pub. Date: Mar. 1, 2012 (54) ELECTRICSHAVER (52) U.S. Cl.... 30/527 (57) ABSTRACT

(12) United States Patent (10) Patent No.: US 6,705,355 B1

USOO670.5355B1 (12) United States Patent (10) Patent No.: US 6,705,355 B1 Wiesenfeld (45) Date of Patent: Mar. 16, 2004 (54) WIRE STRAIGHTENING AND CUT-OFF (56) References Cited MACHINE AND PROCESS NEAN

USOO670.5355B1 (12) United States Patent (10) Patent No.: US 6,705,355 B1 Wiesenfeld (45) Date of Patent: Mar. 16, 2004 (54) WIRE STRAIGHTENING AND CUT-OFF (56) References Cited MACHINE AND PROCESS NEAN

UNITED STATES PATENT OFFICE,

10 30 35 40 45 50 UNITED STATES PATENT OFFICE, FRANK SPALDING, OF PROVIDENCE, RHODE ISLAND, ASSIGNOR TO BROWN & SHARPE MANUFACTURING COMPANY, OF PROVIDENCE, RHODE ISLAND. NIICROMETER-CALIPER.S. 1,001,471.

10 30 35 40 45 50 UNITED STATES PATENT OFFICE, FRANK SPALDING, OF PROVIDENCE, RHODE ISLAND, ASSIGNOR TO BROWN & SHARPE MANUFACTURING COMPANY, OF PROVIDENCE, RHODE ISLAND. NIICROMETER-CALIPER.S. 1,001,471.

(12) United States Patent

(12) United States Patent Mack USOO686.0488B2 (10) Patent No.: (45) Date of Patent: Mar. 1, 2005 (54) DRILL CHUCK WITH FRONT-END SHIELD (75) Inventor: Hans-Dieter Mack, Sontheim (DE) (73) Assignee: Rohm

(12) United States Patent Mack USOO686.0488B2 (10) Patent No.: (45) Date of Patent: Mar. 1, 2005 (54) DRILL CHUCK WITH FRONT-END SHIELD (75) Inventor: Hans-Dieter Mack, Sontheim (DE) (73) Assignee: Rohm

April 5, C. KEMP

April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2 Sheets-Sheet l April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2. Sheets-Sheet 2 ATTORNEYS. Patented Apr., 1938 2,113,02

April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2 Sheets-Sheet l April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2. Sheets-Sheet 2 ATTORNEYS. Patented Apr., 1938 2,113,02

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

(19) United States US 201701 01828A1 (12) Patent Application Publication (10) Pub. No.: US 2017/0101828A1 McGowan et al. (43) Pub. Date: (54) PRE-INSTALLED ANTI-ROTATION KEY (52) U.S. Cl. FOR THREADED

(19) United States US 201701 01828A1 (12) Patent Application Publication (10) Pub. No.: US 2017/0101828A1 McGowan et al. (43) Pub. Date: (54) PRE-INSTALLED ANTI-ROTATION KEY (52) U.S. Cl. FOR THREADED

April 10, L. MALICAY 2,373,584 COCOANUT CUTTING MACHINE. HEDEar N--- acacases. \ Zeanaze A? a leay. 20%ive s?alafa.

April 10, 1945. L. MALICAY 2,373,584 COCOANUT CUTTING MACHINE Filed Sept. 23, 1943 4 Sheets-Sheet l Y HEDEar N--- acacases \ Zeanaze A? a leay 20%ive s?alafa. April 10, 1945. L. MACAY 2,373,584 COCOANUT

April 10, 1945. L. MALICAY 2,373,584 COCOANUT CUTTING MACHINE Filed Sept. 23, 1943 4 Sheets-Sheet l Y HEDEar N--- acacases \ Zeanaze A? a leay 20%ive s?alafa. April 10, 1945. L. MACAY 2,373,584 COCOANUT

United States Patent (19) (11) 3,865,005 Carree (45) Feb. 11, 1975

United States Patent (19) (11) 3,865,005 Carree (45) Feb. 11, 1975 54) WIND MUSICAL INSTRUMENT 2,560,083 7/1951 Bullock... 84/385 75) Inventor: Robert Victor Carree, Mantes-la-Ville, France Primary Examiner-Lawrence

United States Patent (19) (11) 3,865,005 Carree (45) Feb. 11, 1975 54) WIND MUSICAL INSTRUMENT 2,560,083 7/1951 Bullock... 84/385 75) Inventor: Robert Victor Carree, Mantes-la-Ville, France Primary Examiner-Lawrence

Turning and Related Operations

Turning and Related Operations Turning is widely used for machining external cylindrical and conical surfaces. The workpiece rotates and a longitudinally fed single point cutting tool does the cutting.

Turning and Related Operations Turning is widely used for machining external cylindrical and conical surfaces. The workpiece rotates and a longitudinally fed single point cutting tool does the cutting.

Student, Department of Mechanical Engineering, Knowledge Institute of Technology, Salem, Tamilnadu (1,3)

International Journal of Scientific & Engineering Research, Volume 7, Issue 5, May-2016 11 Combined Drilling and Tapping Machine by using Cone Mechanism N.VENKATESH 1, G.THULASIMANI 2, S.NAVEENKUMAR 3,

International Journal of Scientific & Engineering Research, Volume 7, Issue 5, May-2016 11 Combined Drilling and Tapping Machine by using Cone Mechanism N.VENKATESH 1, G.THULASIMANI 2, S.NAVEENKUMAR 3,

Feb. 12, 1952 E. ALTMAN 2,585,073 PEACH PITTING MACHINE INVENTOR. BY 6%au-v62. ATTORNEYS.

Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet INVENTOR BY 6%au-v62. ATTORNEYS. Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet 2 /6- /2 72.2. Zsz27Z ZZZZZZZZ,

Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet INVENTOR BY 6%au-v62. ATTORNEYS. Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet 2 /6- /2 72.2. Zsz27Z ZZZZZZZZ,

1567,6077. v w. A. VAN BERKEL. SLICING MACHINE. Argucmou FILED AFR.28;'1913.'_~ Patented May'2s, Q SHEETS SHEET I.

1567,6077. v w. A. VAN BERKEL. SLICING MACHINE. Argucmou FILED AFR.28;'1913.'_~ Patented May'2s, 1918. Q SHEETS SHEET I. 1, 2676,.07. W. A. VAN BERKEL. SLICING MACHENE. t4 N Q... : mm in n a Mm. 0mm new

1567,6077. v w. A. VAN BERKEL. SLICING MACHINE. Argucmou FILED AFR.28;'1913.'_~ Patented May'2s, 1918. Q SHEETS SHEET I. 1, 2676,.07. W. A. VAN BERKEL. SLICING MACHENE. t4 N Q... : mm in n a Mm. 0mm new

Force multipliers and speed multipliers Machines can make work easier by reducing the amount of force necessary to move an object or increasing the

MACHINES A machine is a device that makes work easier by transmitting or transforming energy. They have been used since ancient times to help people move heavy objects, bring substances like water from

MACHINES A machine is a device that makes work easier by transmitting or transforming energy. They have been used since ancient times to help people move heavy objects, bring substances like water from

MACHINE TOOLS GRINDING MACHINE TOOLS

MACHINE TOOLS GRINDING MACHINE TOOLS GRINDING MACHINE TOOLS Grinding in generally considered a finishing operation. It removes metal comparatively in smaller volume. The material is removed in the form

MACHINE TOOLS GRINDING MACHINE TOOLS GRINDING MACHINE TOOLS Grinding in generally considered a finishing operation. It removes metal comparatively in smaller volume. The material is removed in the form

Appl. No.: 619,775 Filed: Nov. 29, 1990 Int. Cl... E21B 4/02 U.S. Cl /907. 1; 175/ /95, 97, 282,303,

United States Patent (19) Justman et al. (54) (75) (73) 21 22 (51) (52) (58) 56) BEARING STRUCTURE FOR DOWNHOLE MOTORS Inventors: Dan B. Justman, Houston; George A. Cross, Kingwood, both of Tex. Assignee:

United States Patent (19) Justman et al. (54) (75) (73) 21 22 (51) (52) (58) 56) BEARING STRUCTURE FOR DOWNHOLE MOTORS Inventors: Dan B. Justman, Houston; George A. Cross, Kingwood, both of Tex. Assignee:

THREAD CUTTING & FORMING

THREAD CUTTING & FORMING Threading, Thread Cutting and Thread Rolling: Machining Threads on External Diameters (shafts) Tapping: Machining Threads on Internal Diameters (holes) Size: Watch to 10 shafts

THREAD CUTTING & FORMING Threading, Thread Cutting and Thread Rolling: Machining Threads on External Diameters (shafts) Tapping: Machining Threads on Internal Diameters (holes) Size: Watch to 10 shafts

A. BURGESS. FOLDING MAGAZINE GUN. No. 524,800.

(No Model.) A. BURGESS. FOLDING MAGAZINE GUN. 2 Sheets-Sheet 1. No. 524,800. Patented Aug. 21, 18-94. 5%?., gllfl'll'l'lllllll 7/////////A (No Model.) No. 524,800. F 0 L AM UM RA G GA Z Sm E SE.G U. N..2.S

(No Model.) A. BURGESS. FOLDING MAGAZINE GUN. 2 Sheets-Sheet 1. No. 524,800. Patented Aug. 21, 18-94. 5%?., gllfl'll'l'lllllll 7/////////A (No Model.) No. 524,800. F 0 L AM UM RA G GA Z Sm E SE.G U. N..2.S

Unit4 31. UnitS 39. Unit 6 47

Preface..................... xi About the Author......... xiii Acknowledgments... xiv Unit 1 1 Bases for Interpreting Drawings........ I Visible Lines............. 3 Lettering on Drawings... 3 Sketching...

Preface..................... xi About the Author......... xiii Acknowledgments... xiv Unit 1 1 Bases for Interpreting Drawings........ I Visible Lines............. 3 Lettering on Drawings... 3 Sketching...

April 3, 1962 K. H. WILSON 3,028,197. Filed July 29, Sheets-Sheet 1. a.4%- AT. To RNEYS

April 3, 1962 K. H. WILSON 3,028,197 NESTABLE COMBINATI ON TABLE AND BENCH STRUCTURE Filed July 29, 1958 4. Sheets-Sheet 1 a.4%- AT. To RNEYS April 3, 1962 K. H. WILSON 3,028,197 NESTABLE COMBINATION TABLE

April 3, 1962 K. H. WILSON 3,028,197 NESTABLE COMBINATI ON TABLE AND BENCH STRUCTURE Filed July 29, 1958 4. Sheets-Sheet 1 a.4%- AT. To RNEYS April 3, 1962 K. H. WILSON 3,028,197 NESTABLE COMBINATION TABLE

TECHNICAL MANUAL OPERATOR S, ORGANIZATIONAL, DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE MANUAL (INCLUDING REPAIR PARTS UST) FOR

TECHNICAL MANUAL OPERATOR S, ORGANIZATIONAL, DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE MANUAL (INCLUDING REPAIR PARTS UST) FOR MILLING MACHINE MODEL NO. 4 (BURKE DIVISION POWERMATIC/HOUDAILLE, INC.)

TECHNICAL MANUAL OPERATOR S, ORGANIZATIONAL, DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE MANUAL (INCLUDING REPAIR PARTS UST) FOR MILLING MACHINE MODEL NO. 4 (BURKE DIVISION POWERMATIC/HOUDAILLE, INC.)

(12) United States Patent (10) Patent No.: US 6,663,057 B2

USOO6663057B2 (12) United States Patent (10) Patent No.: US 6,663,057 B2 Garelick et al. (45) Date of Patent: Dec. 16, 2003 (54) ADJUSTABLE PEDESTAL FOR BOAT 5,297.849 A * 3/1994 Chancellor... 297/344.

USOO6663057B2 (12) United States Patent (10) Patent No.: US 6,663,057 B2 Garelick et al. (45) Date of Patent: Dec. 16, 2003 (54) ADJUSTABLE PEDESTAL FOR BOAT 5,297.849 A * 3/1994 Chancellor... 297/344.

PRODUCTION ENGINEERING LAB II

Department of Mechanical Engineering LAB MANUAL FOR PRODUCTION ENGINEERING LAB II DEPT. OF MECHANICAL ENGINEERING 1. SHAPER 1.1 INTRODUCTION The shaper is a reciprocating type of machine tool intended

Department of Mechanical Engineering LAB MANUAL FOR PRODUCTION ENGINEERING LAB II DEPT. OF MECHANICAL ENGINEERING 1. SHAPER 1.1 INTRODUCTION The shaper is a reciprocating type of machine tool intended

United States Patent (19) Brown

United States Patent (19) Brown (54) PATIENT LIFT AND EXERCISE APPARATUS 76) Inventor: Cicero C. Brown, 5429 Sturbridge Dr., Houston, Tex. 22 Filed: Sept. 7, 1973 (21) Appl. No.: 395,138 (52) U.S. Cl...

United States Patent (19) Brown (54) PATIENT LIFT AND EXERCISE APPARATUS 76) Inventor: Cicero C. Brown, 5429 Sturbridge Dr., Houston, Tex. 22 Filed: Sept. 7, 1973 (21) Appl. No.: 395,138 (52) U.S. Cl...

T United States Patent (19) Sutherland 19, N, 11) 4,258, Mar. 31, Ezz2a i

United States Patent (19) Sutherland 54 MICROSURGICAL INSTRUMENTS 75 Inventor: Geoffrey Sutherland, Melbourne, Australia 73 Assignee: The University of Melbourne, Parkville, Australia 21 Appl. No.: 7,778

United States Patent (19) Sutherland 54 MICROSURGICAL INSTRUMENTS 75 Inventor: Geoffrey Sutherland, Melbourne, Australia 73 Assignee: The University of Melbourne, Parkville, Australia 21 Appl. No.: 7,778

SINGER 531B-8BL. From the library of: Superior Sewing Machine & Supply LLC

SINGER 53B-8BL PERSPECTIVE THREAD TENSION, GUIDE, NEEDLE PLATE i SINGER 4 THREAD TENSION, GUIDE, NEEDLE PLATE 3 Fig. No. Parts No. Quantity Name of Parts Fig. No. Parts No. Quantity Name of Parts 0698

SINGER 53B-8BL PERSPECTIVE THREAD TENSION, GUIDE, NEEDLE PLATE i SINGER 4 THREAD TENSION, GUIDE, NEEDLE PLATE 3 Fig. No. Parts No. Quantity Name of Parts Fig. No. Parts No. Quantity Name of Parts 0698

Singer From the library of: Superior Sewing Machine & Supply LLC

Singer 69-14 LST OF PARTS COMPLETE NO. 69=14 MACHNE The Singer Manufacturing Co. ) LST OF PARTS COMPLETE FOR No. 69=14 Machine Central Bobbin, makes 18 staying and three fastening or tying stitches in

Singer 69-14 LST OF PARTS COMPLETE NO. 69=14 MACHNE The Singer Manufacturing Co. ) LST OF PARTS COMPLETE FOR No. 69=14 Machine Central Bobbin, makes 18 staying and three fastening or tying stitches in

TURNING BORING TURNING:

TURNING BORING TURNING: FACING: Machining external cylindrical and conical surfaces. Work spins and the single cutting tool does the cutting. Done in Lathe. Single point tool, longitudinal feed. Single

TURNING BORING TURNING: FACING: Machining external cylindrical and conical surfaces. Work spins and the single cutting tool does the cutting. Done in Lathe. Single point tool, longitudinal feed. Single

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States US 2011 O254338A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0254338 A1 FISHER, III et al. (43) Pub. Date: Oct. 20, 2011 (54) MULTI-PAWL ROUND-RECLINER MECHANISM (76)

(19) United States US 2011 O254338A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0254338 A1 FISHER, III et al. (43) Pub. Date: Oct. 20, 2011 (54) MULTI-PAWL ROUND-RECLINER MECHANISM (76)

United States Patent (19) Breslow

United States Patent (19) Breslow (54. SHELVING ASSEMBLY 75 Inventor: David S. Breslow, Chicago, Ill. 73 Assignee: RTC Industries, Inc., Chicago, Ill. (21) Appl. No.: 325,395 22 Filed: Mar. 20, 1989 5ll

United States Patent (19) Breslow (54. SHELVING ASSEMBLY 75 Inventor: David S. Breslow, Chicago, Ill. 73 Assignee: RTC Industries, Inc., Chicago, Ill. (21) Appl. No.: 325,395 22 Filed: Mar. 20, 1989 5ll

EXIT DEVICE OPERATION FIRE DOOR LABELS, STRIKES AND FRAME SCREWS FOR INFORMATION CALL OR VISIT RITEDOOR.COM

RECORD & LABELS WHAT THIS OWNER'S CAN DO FOR YOU It explains exactly how The Rite Door operates. It explains periodic maintenance requirements necessary to assure reliable operation. It explains simple

RECORD & LABELS WHAT THIS OWNER'S CAN DO FOR YOU It explains exactly how The Rite Door operates. It explains periodic maintenance requirements necessary to assure reliable operation. It explains simple

UNITED STATES PATENT OFFICE.

I10 20 25 30 35 40 45 50 55 UNITED STATES PATENT OFFICE. JOHN ERICSSON, OF LONDON, ENGLAND. PROPELLING STEAM VESSELS. Specification of Letters Patent No. 588,.dated February 1, 1838. To all vhon, it may

I10 20 25 30 35 40 45 50 55 UNITED STATES PATENT OFFICE. JOHN ERICSSON, OF LONDON, ENGLAND. PROPELLING STEAM VESSELS. Specification of Letters Patent No. 588,.dated February 1, 1838. To all vhon, it may

JARVIS. Model BR-3 Blade Reconditioner ... EQUIPMENT TABLE OF

- Model BR-3 Blade Reconditioner EQUIPMENT SELECTION.......... Ordering No. TABLE OF CONTENTS............................ Page Model BR-3 (100 mm Blade) 115V/60Hz............ 4011003 220V/50Hz............

- Model BR-3 Blade Reconditioner EQUIPMENT SELECTION.......... Ordering No. TABLE OF CONTENTS............................ Page Model BR-3 (100 mm Blade) 115V/60Hz............ 4011003 220V/50Hz............

25 N WSZ, SN2. United States Patent (19) (11) 3,837,162. Meitinger. (45) Sept. 24, 1974 % N. and carried on a projecting portion which is rigidly

O United States Patent (19) Meitinger 54) DEVICE FOR ADJUSTING THE DIAL TRAIN OF WATCHES 76 Inventor: Heinz Meitinger, Theodor-Heuss-Str. 16 D-7075, Mutlangen, Germany 22 Filed: Mar. 26, 1973 (21) Appl.

O United States Patent (19) Meitinger 54) DEVICE FOR ADJUSTING THE DIAL TRAIN OF WATCHES 76 Inventor: Heinz Meitinger, Theodor-Heuss-Str. 16 D-7075, Mutlangen, Germany 22 Filed: Mar. 26, 1973 (21) Appl.

~) / 7&0. Gleason No. 610 Universal Hypoid Gear Machine

~) / 7&0 Gleason No. 610 Universal Hypoid Gear Machine Gleason No. 610 The No. 610 Universal Hypoid Gear Machine sets new standards in precision high speed roughing and finishing of medium and large non-generated

~) / 7&0 Gleason No. 610 Universal Hypoid Gear Machine Gleason No. 610 The No. 610 Universal Hypoid Gear Machine sets new standards in precision high speed roughing and finishing of medium and large non-generated

DRILL GRINDING ATTACHMENT

DRILL GRINDING ATTACHMENT To suit TM6025Q TOOL AND CUTTER GRINDER OPERATION S MANUAL 1 0º 270º 90º 180º INTRODUCTION Before grinding any cutters, you must set up the attachment to suit the type of cutter

DRILL GRINDING ATTACHMENT To suit TM6025Q TOOL AND CUTTER GRINDER OPERATION S MANUAL 1 0º 270º 90º 180º INTRODUCTION Before grinding any cutters, you must set up the attachment to suit the type of cutter

S-85SCH

4411-4423-4432-4443-4452 5511-5523-5532-5554 44S-85SCH Service Manual 104 73 14-26 2014-02-24 CONTENTS 1. Names of principal parts...2 2. Removing methods of external parts 2-1 Sewing table...3 2-2 Face

4411-4423-4432-4443-4452 5511-5523-5532-5554 44S-85SCH Service Manual 104 73 14-26 2014-02-24 CONTENTS 1. Names of principal parts...2 2. Removing methods of external parts 2-1 Sewing table...3 2-2 Face

inventors L.f. texford J. F. JONES, L. P. REXFORD & H. N. GORES. 1,123,885. Patented Jan. 5, SHEETS-S HEET ), / 42- f.n.g.

1,123,885. J. F. JONES, L. P. REXFORD & H. N. GORES. MACHINE FOR MAKING CORRUGATED PAPER BOX BLANKS, APPLICATION FILED JUNE 2, 1913. w r Patented Jan. 5, 1915. - 4 SHEETS-S HEET ), ES t a & 22 ------ *:::St

1,123,885. J. F. JONES, L. P. REXFORD & H. N. GORES. MACHINE FOR MAKING CORRUGATED PAPER BOX BLANKS, APPLICATION FILED JUNE 2, 1913. w r Patented Jan. 5, 1915. - 4 SHEETS-S HEET ), ES t a & 22 ------ *:::St

11 THE. OBIRAKY * CHI CAGOc. ^bruw-w^rw.-&. ? 1894 PRESENTED BY

11 THE OBIRAKY * CHI CAGOc ^bruw-w^rw.-&.? 1894 iwmm wm PRESENTED BY ^w%# w^ f + % # # ^ ^ ^ ^ ^ - M> ^ -4 * * ^-.# ^ # ^ in ^ # ^;^pt -^ ^ ^ ^ ^'# ^ ^;MK^ * * * ^ - * f * ^ A A * * ^F * f $ H^'^ ^ * *

11 THE OBIRAKY * CHI CAGOc ^bruw-w^rw.-&.? 1894 iwmm wm PRESENTED BY ^w%# w^ f + % # # ^ ^ ^ ^ ^ - M> ^ -4 * * ^-.# ^ # ^ in ^ # ^;^pt -^ ^ ^ ^ ^'# ^ ^;MK^ * * * ^ - * f * ^ A A * * ^F * f $ H^'^ ^ * *

J. C. BARR, INDICATOR LOCK, No. 426,097. Patented Apr. 22, 1890, 222 AN-8. S 2 P 9. it? SEH) sts

(No Model.) J. C. BARR, INDICATOR LOCK, 2 Sheets-Sheet 1. No. 426,097. Patented Apr. 22, 1890, 222 AN-8 Y AN SEH) S 2 P 9. it? sts (No Model.) 2. Sheets-Sheet 2. J. C. BARR, INDICATOR LOCK, No. 426,097,

(No Model.) J. C. BARR, INDICATOR LOCK, 2 Sheets-Sheet 1. No. 426,097. Patented Apr. 22, 1890, 222 AN-8 Y AN SEH) S 2 P 9. it? sts (No Model.) 2. Sheets-Sheet 2. J. C. BARR, INDICATOR LOCK, No. 426,097,

Aug. 23, ,950,048 H. FP. LUHIN COMPUTER FOR WERIFYING NUMB ERS. Filed Jan. 6, 1954 !LL ?? INVENTOR, Hzqaws AP Zu'Azawr.

Aug. 23, 1960 Filed Jan. 6, 1954 H. FP. LUHIN COMPUTER FOR WERIFYING NUMB ERS 3. Sheets -Sheet!LL---------?? t INVENTOR, Hzqaws AP Zu'Azawr 477 OAA/Exs Aug. 23, 1960 Filed Jan. 6, 1954 H. FP, UHN COMPUTER

Aug. 23, 1960 Filed Jan. 6, 1954 H. FP. LUHIN COMPUTER FOR WERIFYING NUMB ERS 3. Sheets -Sheet!LL---------?? t INVENTOR, Hzqaws AP Zu'Azawr 477 OAA/Exs Aug. 23, 1960 Filed Jan. 6, 1954 H. FP, UHN COMPUTER

Ay:44, 444-, INven TOR HARVEY R. PLUMMER. Jan. 3, 1967 H. R. PLUMMER 3,295,187. ArTws, Filed March l, Sheets-Sheet

Jan. 3, 1967 H. R. PLUMMER Filed March l, 1965 2 Sheets-Sheet INven TOR HARVEY R. PLUMMER Ay:44, 444-, 14-42--- ArTws, Jan. 3, 1967 H. R. PUMMER Filed March 1, 1965 2. Sheets-Sheet 2 INVENTOR HARVEY R.

Jan. 3, 1967 H. R. PLUMMER Filed March l, 1965 2 Sheets-Sheet INven TOR HARVEY R. PLUMMER Ay:44, 444-, 14-42--- ArTws, Jan. 3, 1967 H. R. PUMMER Filed March 1, 1965 2. Sheets-Sheet 2 INVENTOR HARVEY R.

Machining. Module 6: Lathe Setup and Operations. (Part 2) Curriculum Development Unit PREPARED BY. August 2013

Machining Module 6: Lathe Setup and Operations (Part 2) PREPARED BY Curriculum Development Unit August 2013 Applied Technology High Schools, 2013 Module 6: Lathe Setup and Operations (Part 2) Module Objectives

Machining Module 6: Lathe Setup and Operations (Part 2) PREPARED BY Curriculum Development Unit August 2013 Applied Technology High Schools, 2013 Module 6: Lathe Setup and Operations (Part 2) Module Objectives

Jan. 17, 1956 R. N. BROWN 2,731,271 COMBINED DEALER, SHUFFLER AND TRAY FOR PLAYING CARDS AOBEAT W. BAOWW, INVENTOR. A 77OAPWE).

Jan. 17, 1956 R. N. BROWN 2,731,271 COMBINED DEALER, SHUFFLER AND TRAY FOR PLAYING CARDS Filed July l4, 1952 3. Sheets-Sheet l BY AOBEAT W. BAOWW, INVENTOR. & faaz A 77OAPWE). Jan. 17, 1956 R. N. BROWN

Jan. 17, 1956 R. N. BROWN 2,731,271 COMBINED DEALER, SHUFFLER AND TRAY FOR PLAYING CARDS Filed July l4, 1952 3. Sheets-Sheet l BY AOBEAT W. BAOWW, INVENTOR. & faaz A 77OAPWE). Jan. 17, 1956 R. N. BROWN

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 20050O28668A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0028668A1 Teel (43) Pub. Date: Feb. 10, 2005 (54) WRIST POSITION TRAINING ASSEMBLY (76) Inventor: Kenneth

(19) United States US 20050O28668A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0028668A1 Teel (43) Pub. Date: Feb. 10, 2005 (54) WRIST POSITION TRAINING ASSEMBLY (76) Inventor: Kenneth

UNIT 5: Indexing: Simple, compound, differential and angular indexing calculations. Simple problems on simple and compound indexing.

UNIT 5: Milling machines: Classification, constructional features, milling cutters nomenclature, milling operations, up milling and down milling concepts. Indexing: Simple, compound, differential and angular

UNIT 5: Milling machines: Classification, constructional features, milling cutters nomenclature, milling operations, up milling and down milling concepts. Indexing: Simple, compound, differential and angular

No. 648,930. Patented May 8, H. J. DOUGHTY. - MANUFACTURE OF CONTINUOUs TUBINGS OR COVERINGS OF RUBBER.

No. 648,930. Patented May 8, 1900. H. J. DOUGHTY. - MANUFACTURE OF CONTINUOUs TUBINGS OR COVERINGS OF RUBBER. (Application filed Dec. 17, 1898. (No Model.) 3 sheets-sheet. Z5 ZB Nissa as us S3) aaaaaaaaaaaaaaaaaaaaaaaa.

No. 648,930. Patented May 8, 1900. H. J. DOUGHTY. - MANUFACTURE OF CONTINUOUs TUBINGS OR COVERINGS OF RUBBER. (Application filed Dec. 17, 1898. (No Model.) 3 sheets-sheet. Z5 ZB Nissa as us S3) aaaaaaaaaaaaaaaaaaaaaaaa.

Instruction Sheet MCHE 365 & I-Tech 344 Lathe & Mill Machining Operations Pencil Organizer Project, FALL 2015

Instruction Sheet MCHE 365 & I-Tech 344 Lathe & Mill Machining Operations Pencil Organizer Project, FALL 2015 1 Always flip to 1 st page & leave your drawings & instructions on your Machine at end of class.

Instruction Sheet MCHE 365 & I-Tech 344 Lathe & Mill Machining Operations Pencil Organizer Project, FALL 2015 1 Always flip to 1 st page & leave your drawings & instructions on your Machine at end of class.

ROOP LAL Unit-6 Shaper & Planer Mechanical Engineering Department

Notes: shapers and planers Basic Mechanical Engineering (Part B ) 1 Introduction: Both shapers and planers are machine tools which produce a flat surface. They are capable of machining a horizontal, vertical

Notes: shapers and planers Basic Mechanical Engineering (Part B ) 1 Introduction: Both shapers and planers are machine tools which produce a flat surface. They are capable of machining a horizontal, vertical

(No Model.) Patented March 1, T. HALL. No. 238, Sheets-Sheet 1, Ateya.

(No Model.) T. HALL. 5 Sheets-Sheet 1, No. 238,387. Patented March 1, Ateya. (No Model.) 5 Sheets-Sheet 2 T. HALL. Type Writer, No. 238,387. Patented March 1, 1881.. t i. Hill l t" hit s Hit' s (SE), (s)

(No Model.) T. HALL. 5 Sheets-Sheet 1, No. 238,387. Patented March 1, Ateya. (No Model.) 5 Sheets-Sheet 2 T. HALL. Type Writer, No. 238,387. Patented March 1, 1881.. t i. Hill l t" hit s Hit' s (SE), (s)

ME MANUFACTURING TECHNOLOGY LABORATORY-I VARUVAN VADIVELAN INSTITUTE OF TECHNOLOGY DHARMAPURI LAB MANUAL

VARUVAN VADIVELAN INSTITUTE OF TECHNOLOGY DHARMAPURI 636 703 ME 6311 - MANUFACTURING TECHNOLOGY LABORATORY-I REGULATION 2013 LAB MANUAL BRANCH YEAR / SEM MECHANICAL ENGINEERING II YEAR & III SEMESTER D

VARUVAN VADIVELAN INSTITUTE OF TECHNOLOGY DHARMAPURI 636 703 ME 6311 - MANUFACTURING TECHNOLOGY LABORATORY-I REGULATION 2013 LAB MANUAL BRANCH YEAR / SEM MECHANICAL ENGINEERING II YEAR & III SEMESTER D

a E. Say 1,272, Né 2NR22. af (16 af staf22n Patented July 16, (NSXN BS ANN21 -Z % (7/A 7) 2xLilly

1,272,589. W, A. WHITNEY, BALL BEARING SACK, APPLICATION filed Aug. 2, 1917, Patented July 16, 1918. 2 SHEETS-SHEET, 2Z. S&S Say SS22 R 2NR22. a- -- 2 2222% 3 2 s2. R 12 V NN 2xLilly 22 5Né af (16 af272-17

1,272,589. W, A. WHITNEY, BALL BEARING SACK, APPLICATION filed Aug. 2, 1917, Patented July 16, 1918. 2 SHEETS-SHEET, 2Z. S&S Say SS22 R 2NR22. a- -- 2 2222% 3 2 s2. R 12 V NN 2xLilly 22 5Né af (16 af272-17

Crestline Dampening System. Installation Instructions. Ryobi 2700, 2800, 3200, 3200E Itek 950, 960, 975 Parent. X /98 Rev-A

Crestline Dampening System Installation Instructions Ryobi 2700, 2800, 3200, 3200E Itek 950, 960, 975 Parent X88-30 3/98 Rev-A GENERAL INFORMATION ATTENTION CRESTLINE DAMPENER OWNER! Accel Graphic Systems

Crestline Dampening System Installation Instructions Ryobi 2700, 2800, 3200, 3200E Itek 950, 960, 975 Parent X88-30 3/98 Rev-A GENERAL INFORMATION ATTENTION CRESTLINE DAMPENER OWNER! Accel Graphic Systems

2x2 EARCEPOST APPROVED IMPORTANT SYSA NEX2 N - May 21, 1963 T, A, SULKE 3, (ZW, Filed Aug. 28, 196l AR MAIL RUBBER STAMP DEVICE ATTORNEYS

May 21, 1963 T, A, SULKE 3,0904 RUBBER STAMP DEVICE Filed Aug. 28, 196l AR MAIL EARCEPOST APPROVED IMPORTANT 22 SN &KNS SYSA (ZW, SS NEX2 N - 2x2 S&N 2. A Ya Ya Y A SSSSSSSSSS INVENTOR Thomas Sulkie ATTORNEYS

May 21, 1963 T, A, SULKE 3,0904 RUBBER STAMP DEVICE Filed Aug. 28, 196l AR MAIL EARCEPOST APPROVED IMPORTANT 22 SN &KNS SYSA (ZW, SS NEX2 N - 2x2 S&N 2. A Ya Ya Y A SSSSSSSSSS INVENTOR Thomas Sulkie ATTORNEYS

Operating Instructions and Parts Manual Electronic Variable Speed Turret Mill Model JTM-1050EVS

Operating Instructions and Parts Manual Electronic Variable Speed Turret Mill Model JTM-1050EVS JET 427 New Sanford Road LaVergne, Tennessee 37086 Part No. M-690060 Ph.: 800-274-6848 Revision G1 06/2015

Operating Instructions and Parts Manual Electronic Variable Speed Turret Mill Model JTM-1050EVS JET 427 New Sanford Road LaVergne, Tennessee 37086 Part No. M-690060 Ph.: 800-274-6848 Revision G1 06/2015

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1. (54) HOLDER FOR A GUIDE SHOE OF A (30) Foreign Application Priority Data

(19) United States US 201600.40441A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0040441 A1 Dingler (43) Pub. Date: (54) HOLDER FOR A GUIDE SHOE OF A (30) Foreign Application Priority Data

(19) United States US 201600.40441A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0040441 A1 Dingler (43) Pub. Date: (54) HOLDER FOR A GUIDE SHOE OF A (30) Foreign Application Priority Data

United States Patent (19) Schreuders

United States Patent (19) Schreuders 54 DEVICE FOR CUTTING GAS CONCRETE (75) Inventor: Willem J. Schreuders, Staphorst, Netherlands 73) Assignee: Durox Gasbeton B.V., Netherlands (21) Appl. No.: 149,677

United States Patent (19) Schreuders 54 DEVICE FOR CUTTING GAS CONCRETE (75) Inventor: Willem J. Schreuders, Staphorst, Netherlands 73) Assignee: Durox Gasbeton B.V., Netherlands (21) Appl. No.: 149,677

*****??SR??????R. May 19, ,638, Sheets-Sheet 1. Attorneys. Filed Sept. 21, Inventor T, HNOLE

May 19, 1953 Filed Sept. 21, 1950 T, HNOLE WEFT DETECTOR AND STOP MOTION FOR WEAVING LOOMS *****??SR??????R 2,638,942 3 Sheets-Sheet 1 VA.V. AYAYAY S. SY N S SL SS S SS SS SS SSSSSLSSSSS S ------- N I

May 19, 1953 Filed Sept. 21, 1950 T, HNOLE WEFT DETECTOR AND STOP MOTION FOR WEAVING LOOMS *****??SR??????R 2,638,942 3 Sheets-Sheet 1 VA.V. AYAYAY S. SY N S SL SS S SS SS SS SSSSSLSSSSS S ------- N I

MODEL D DIESEL PILE HAMMER

AMERICAN PILEDRIVING EQUIPMENT, INC. MODEL D125-42 DIESEL PILE HAMMER SPARE PARTS BOOK Corporate Office 7032 S. 196th Street Kent, WA, USA 98032 Tel: 1-800-248-8498 Tel: 1-253-872-0141 Fax: 1-253-872-8710

AMERICAN PILEDRIVING EQUIPMENT, INC. MODEL D125-42 DIESEL PILE HAMMER SPARE PARTS BOOK Corporate Office 7032 S. 196th Street Kent, WA, USA 98032 Tel: 1-800-248-8498 Tel: 1-253-872-0141 Fax: 1-253-872-8710

PFAFF. rom the library of: Superior Sewing Machine & Supply LLC. Service Manual Justieranl. engi. 7.92

PFAFF 5642 Service Manual 296-12-13925 Justieranl. engi. 7.92 Notes on safety The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate training.

PFAFF 5642 Service Manual 296-12-13925 Justieranl. engi. 7.92 Notes on safety The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate training.

Types of Simple Machines

Types of Simple Machines The Lever The Lever a rigid bar that is free to turn about a fixed point called the fulcrum Every Lever has three (3) parts: 1. Resistance Force, Input Force or Load, What you

Types of Simple Machines The Lever The Lever a rigid bar that is free to turn about a fixed point called the fulcrum Every Lever has three (3) parts: 1. Resistance Force, Input Force or Load, What you

United States Patent (19) Cox

United States Patent (19) Cox (54) RAPID ACTING C-CLAMP 75) Inventor: Edward A. Cox, Olympia Fields, Ill. 73) Assignee: Wilton Corporation, Palatine, Ill. 21 Appl. No.: 600,763 22 Filed: Apr. 16, 1984

United States Patent (19) Cox (54) RAPID ACTING C-CLAMP 75) Inventor: Edward A. Cox, Olympia Fields, Ill. 73) Assignee: Wilton Corporation, Palatine, Ill. 21 Appl. No.: 600,763 22 Filed: Apr. 16, 1984