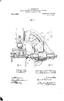

(No Model.) Patented March 1, T. HALL. No. 238, Sheets-Sheet 1, Ateya.

|

|

|

- Everett James

- 5 years ago

- Views:

Transcription

1 (No Model.) T. HALL. 5 Sheets-Sheet 1, No. 238,387. Patented March 1, Ateya.

2 (No Model.) 5 Sheets-Sheet 2 T. HALL. Type Writer, No. 238,387. Patented March 1, t i. Hill l t" hit s Hit' s (SE), (s) s (86.9 t s 6. SS si E. (8) (BGB (3)(E)(E)(E)(EB 5 (E) () (3 CD (EB (EGE) () SSE gigs O (EGE) ()(3)(E) g enessee S. Hi -: & (A) t H Still s S. 2 tees ét: Azzoverdor. 3. &2.Z06. l hi, ERs, Photo-LTHOGRAPHER, WASHINGTON, D.C.

3 (No Model.) 5. Sheets-Sheet 3, T. HALL. Type Writer. No. 238,387. Patented March 1, y Se Re3 M. v. N.W.A A? 2 SS Z 'aaaaaaaaaaaaaaaaaa. zzzzzzzzzzzzzzzzz2 N. c\, ( / A'7. 6. A so 2 r la sy & O -- 1 a A Y' 4. 7 a. ce 1 ca (V) 7 Z /t - sts. y aa Zes. 6 v 17tes. 2:37 v- 1 A (7 were &or. 2. % *,

4 (No Model.) 5. Sheets-Sheet 4, T. HALL, Type Writer. No. 238,387. Patented March 1, OOOOOD : DD DJ OOOOO } DO OO } : OOOOO O OC OJ O (S OOD COO e OOOOOOOOO OOOOOOOO! :, 7" -

5 (No Model.) No. 238, Sheets-Sheet 5. T. HALL, Type Writer, Patented March 1, ES m - - D. t Zpezvez26or. N. PETERs, PHOTo-THOGRAPHER, WASHINGTON, O. C.

6 UNITED STATES PATENT OFFICE. THOMAS HALL OF BROOKLYN, TYPE-WRITER. NEW YORK. O So SPECIFICATION forming part of Letters Patent No. 288,387, dated March 1, Application filed December 1, To all chon it inctly concern:. Beit known that I.THOMAS HALL, of Brook lyn, in the county of Kings and State of New York, have invented a new and useful Im provement in Type. Writers; and I do hereby declare that the following is a full, clear, and exact description of the same. My invention relates to type-writers of that class in which the type are carried on a plate made movable so as to bring any required let ter into alignment with any desired point upon the paper. The Oloject of my invention is to simplify the structure and reduce the number of parts in type-writing machines; to reduce the size and cost, as Well as to render the inachine durable and Serviceable. It consists, primarily, of a movable type form impelled by means of suitable mechan ism over an inking-plate to bring any given letter opposite a hole in said plate, whereby the type may be pressed through said opening and upon the paper beneath. It consists, further, in the combination of a bed-plate, bar, or roller for sustaining the pa per While printing, with an inking-plate, or plate provided with an inking-pad arranged directly over it and provided with an opening for the admission of one of the types; with a type - form in which the separate types are adapted to be depressed independently; and with a plunger directly above the opening in the inking-plate, whereby any given letter of tle type-form is brought into proper position and pressed upon the paper. It also consists in making the type-form flexi ble, whereby any type may be forced through the opening and printing effected withoutcom plication of parts. It finally consists in important details of construction for carrying into effect these lead ing features of my invention, all of which de tails are fully set forth hereinafter and specific ally pointed out in the claims. The general plan of this machine includes a base or platen, on which the paper rests in or der to be printed. This may be a plate, bar, or roller. Over this the paper is fed, either in sheets or from a roll, with a regulated inter mittent notion, to form the lines of writing. This base or platen and the feed-rollers men tioned are a part of the base of the machine. (No model.) The type-form is movable, both for bringing any given letter into alignment with the open ing in the moving plate on which it is carried, and also in order to bring the opening in said plate from the position of one letter to that of the next. The motion required to bring any given letter into alignment with the opening in the plate is directly imparted by movement of the hand grasping a small lever or arm and guiding the same by means of a pointer thereon fitting definitely - arranged holes, any one of which, when the pointer is set there, brings its appropriate letter over the opening, through which it is pressed to print the letter. Further, the motion of this directing-arm is accompa nied or directly followed by a depression of the type-form and its supporting-frame and subse quent elevation, these movements being neces Sary in the act of printing a letter. These movements are made to Operate an escape ment, whereby the perforated plate which car ries the type-form is permitted to move one notch to the right, bringing the type to the Space on the paper appropriate for the next letter. The step-by-step movement of the type-car rying mechanism from left to right to form the necessary spacing is accomplished by means of a spring or equivalent motor acting in con nection with an escapement. This escape ment is of special construction, and consists of an elastic arm, which engages with a rack bar, and is released by the movement neces sary in printing, but advances a limited dis tance in the direction of the movement of the Carriage before again engaging with said rack bar. After its advance and engagement the carriage is moved up to it as to a stop the distance of its advance, and this distance may be varied to vary the spacing. In the following more specific description. the accompanying drawings are referred to, in Which Figure I is a perspective view of my type Writer, showing the top in position for work. Fig. 2 is a plan view of the same. Figs. 3 and 4 are sections on line a ac, Fig. 2, the latter, Fig. 4, showing the type in the act of print. ing. Fig. 5 is a side elevation, and Fig. 6 a. plan view, of the escapement or spacing mech anism. Fig. 7 is a view of the under side of the plate carrying the type-plate, and shows Ioo

7 O IS the link mechanism. Fig. S is a detached view of the type-plate. Fig. 9 represents the ink ing-plate and attachments. Figs. 10 and 11 are bottom views, illustrating different posi tions of the type-form and its actuating mech anism. In these drawings the base of the machine. is represented at 1. It is rectangular in plan, and may be about fourteen inches wide and seven inches from front to rear, though these dimensions may be enlarged or reduced, if found necessary for any special purpose. On the front of this is hinged a frame, the sides 22 of which are slightly raised in the rear, as shown at 33, and support a rack-rod, R, the ends of which are fixed in the said sides. This rod is made round for purposes hereinafter explained, and is provided with grooves run ning around it, to correspond with the notches or teeth in an ordinary rack-bar. Upon it is hinged the plate A, which carries the type form F and other parts auxiliary thereto. Across this frame and supported in the sides thereof is placed the platen or barg, on which the paper rests when impressed by the type. The form of this is shown in Fig. 1, and in section in Fig. 3. It may be greatly changed without departing materially from the gen eral plan of my machine. It may be made in stead in the form of a roller, the bearings of which may be in the sides to which the bar is fixed, or the paper may be held on a flat table and the machine operated on it in the same manner that it does when the paper is on the barg. In front of this bar is a l'oiler, ct, hav ing its bearings in the sides, and over this the paper is moved to the bar or platen g. The shaft of this roller is provided at the left hand end with a pulley, 5, and lever d, the said lever being adapted to give partial rotation to the roller, for moving the paper from line to line, in the same manner as is ordinarily done in machines of this class. This wheel 5 may be smooth, and the end of the lever, which is pivoted in the collar, is placed so as to pinch upon the surface, or the wheel may be notched. The weight of the lever or force of the spring 8 will throw it out of contact, and the roller may then be turned freely backward by means of the milled bead 49. Obviously the paper to be printed may be wound around this roll, or may be passed around it from below, and extended above and over the barg. I have shown the latter and preferred form. Upward movement of the lever d a limited distance will give a regulated amount of movement to the roller a, and thus advance the paper over the barg. The movement of the lever d may be limited by any convenient stop, made adjustable, so that the amount of motion of the roller can be varied and the Width of the space between the lines enlarged or diminished. Over the roller a, on the front thereof, is a spring plate or clip, b, of substantially the same curve as the roller, and adapted to press against its surface. This plate or clip is mounted on a shaft, 4, the bearings of which are in thesides of the machine, said shaft being provided with Springs 15. The spring holds the clip tightly against the paper on the roller a, and the lever 16, fixed upon the shaft 4, when depressed, turns said shaft and lifts the clip from the paper. The lever, of course, acts in opposi tion to the spring. The object of this clip is to hold the paper firmly in place, while it yields sufficiently to allow the paper to be fed by the turning of the roller. The clip is lifted to permit the end of the paper, sheet, or roll to be entered. As shown in Fig. 1, the upper exposed sur face of the clip is marked with a graduated scale, and is so constructed and arranged that the edge serves as a cutter to separate the paper by tearing it against the edge. A simi lar scale is on the bar ', with the marks op posite those on the clip. These correspond to the spacing on the rod R, hereinbefore more fully explained, and serve to indicate the po sition of the printing mechanism upon the paper. On the front plate of the frame of the ma chine is a bar, N, adjustable vertically and held by set-screws 99. The hinged plate B, and indirectly that carrying the printing mech anism, rest upon this bar, and by said bar the position of this mechanism in relation to the paper on the barg is accurately adjusted. On the rear of the machine, behind and a little above the rod R, is the bar ', heretofore referred to. It is preferably square, but has cylindrical ends, which rest in bearings in the sides of the machine, in which it may turn. At the right-hand end it is provided with a bell-hammer, 10, fixed upon it, and adapted, When properly moved, to strike a bell, 11, on the inside of the frame. On barris a trigger, h, adjustable, and held at any desired point by a set-screw. It is adapted to be struck by a stud, 12, on the carriage, as will be explained, and When so struck is thrown backward and instantly released. A spring, f, on the other end of ", returns the bar by rotary motion and causes the hammer to strike the bell, serving thus to indicate when the printing has ap proached near the end of the line. It will be observed that the construction of the frame and base of the machine, as herein before described, gives ample space for the paper. The sheets, if separate sheets be used, may be introduced either from front or rear, and may extend backward under the rod R. as far as necessary; or a roll of paper may be placed in the rear of the barg and be fed up and over said bar. The whole frame of the fixed part of the ma chine rests upon a board or plate, 1, as a basis, and is pivoted at the forward edge, as shown at 14, Fig. 1. By this it may be set to any desired inclination. I proceed now to the description of the mov able part of lny apparatus and the mechanism more directly connected with the printing, 75 9o OO ro5 IO I I5 (25

8 O IS 23S,38? 3 Upon the rod R is hinged a plate, B, by with the pivots secures the whole link means of two side pieces, B'B', to which it is movement and the type-form to the plate A. attached. These side pieces are perforated, It will be understood that either forward so that the rod R passes directly through their and backward or right and left hand motion, to rear ends. The plate B rests at its forward or any resultant of these, can be given to the edge upon the bar N, as heretofore explained, type-form by means of the mechanism above in such a manner that the lower surface of the described, in order to bring any given letter plate B shall come nearly in contact with the to register with the stud J and the hole E in upper surface of the barg. The plate B has the plate B. 75 an opening, E, preferably rectangular, near the Movements necessary to bring any one of center of the plate, and directly over the bar these letters thus to register with the stud Jare (7. Above the plate B is another plate, A, also hinged upon the rod R by means of sleeves 25 25, arranged within the side pieces B B', so that either the upper plate, A, alone, or both A and B together, may be turned upward and backward to rest upon the bar. Underneath the plate A is the printing-form IF. This consists of a rubber plate, having the type upon its lower Surface. It is prefer ably square in shape, and the type are ar ranged in parallel lines in any convenient mall ner, having relation to the frequency of their S. 25> The manner of connecting the type-form to 3O SO 55 the plate A so as to give all the necessary movements thereon, and to permit the stud on plate A to press any given letter of said form through the opening in plate B and upon the paper below, may be described in connection with Figs. 7 and 8, though further illustration is given in Figs. 3 and 4. Referring more particularly to Fig. S, the type-form F will be seen fixed to a frame, K', which serves to give it direct support. The frame is cut out from a plate. Its form is shown on the outside in full, on the inside in dotted, lines. The rubber type-form is fully exposed in the lettered part. The frame K. is pivoted on the links M M at n n, the other ends of these links being pivoted to a frame, K? at Direct movement of the type form to the front of the machine, as by draw ing upon the barf, will swing the links on piv ots to the front, the type-plate, by reason of its pivotal connection at n n, keeping its sides always parallel with the edge of the plate A. The frame K is pivoted to the links H. H. at hit, said links HH being pivoted directly to the plate A at Lateral movement, there fore, of the type-form swings the links M. M., the frame K, and the links HH, the form-frame K turning on pins in m, the links M M on pins 17 17, and the frame K on h it, the form and the frame preserving the parallelism of their sides. The printing-stud J is fixed in the plate, and moves only vertically with the plate. It passes through the slotin the frame K, which slot is made on a radius equal to the length of links F. As the links H swing to the right or left they shift the frame K laterally, and also move it forward, more or less, depending on the amount of lateral deflection, and as the frame moves the stud J travels in the slot. The small collar on the stud (shown in Figs. 3, 4, and 7) holds the frame, and in connection made and determined by means of a plate, I, and arm P. The arm P is hinged upon the front end of the flat bar p, projecting a little 8o in front of the plate A. The arm P may, there fore, be moved up and down on its hinge in relation to the bar p, or by it. The barp, and thereby the type-form, may be drawn out to the front, or pushed back to the rear, or moved 85 from side to side. The plate I has holes pro vided with letters and figures exactly corre sponding in number and position to the letters and figures upon the type-form, these letters and figures being placed so as to be visible at 9o the bottom of the holes each in its proper place. A spur, i, upon the end of P, is adapted to fit into the holes, the upper edges of the holes and the end of the spur being rounded, so that the spur will slip easily into place. 95 The arm P is accurately hinged upon p, so as to be capable only of vertical motion thereon. It is adapted to be grasped between the thumb and fingers, and the construction alnd arrange ment of the parts is such that when the spur Ioo i is set in the hole marked by any given letter, that letter on the type-form is brought directly under the Stud J and over the hole in the plate B. ^ (It will be understood that pressure may be Io5 applied by the hand while grasping the arm P, so as to depress the plate A, and with it the stud which forces the type upon paper. The plate A is raised by devices elsewhere re ferred to, consisting of the shaft 2 and arms 19, IIo which arms are forced downward by the spring upon the shaft. The flat bar p slides freely between a rod, Q, and a bar, n, the latter be ing connected to the plate A by short offsets 1S. The rod Q passes through these offsets II 5 and turns therein. At its ends it is provided with arms 19, bent at right angles to the rod, and bearing upon the sides B of the lower plate. A coiled spring, 20, on the rod Q. throws these arms downward, thus tending to I2O separate the forward ends of plates A and B; but the springs yield readily to pressure and allow the plate A, when pressed to approach the plate B, thus pressing the stud J upon the letter of the type-form directly underneath it, I 25 and causing said letter to project through the plate B upon the paper, which rests upon the barg below. The upper plate, A, is connected to the lower, B, by means of a Spring-catch, af, on the right-hand side of the machine. A I3o thumb-piece, a, is fixed upon the plate A, on the edge of the hole a, through which

9 O O 45 the catch a? projects. By this thumb-piece the catch is easily detached and the plate lifted. Sufficient play is allowed by the catch for the necessary vertical movement of the plate A. It will be obvious, from the description al ready given, that all the movements, both the horizontal of the type-form and the vertical of the plate A, to which the type-form is at tached, are effected by means of the arm P, the horizontal motions of the arm, as it is moved to any given hole in the plate I, regulating the position of the type, and the downward pressure of the same arm as it is thrust into the hole pressing down the plate A against the spring-arms 19, and pressing the stud J against the type, as heretofore described. The lateral movemelt of the Whole structure by which the types are carried is effected by means of the coiled spring S Within the bar rel S', and is regulated by the escapement at tached to the right-hand side of the movable plates. The spring S is attached to the plate A by means of a stud, S, which serves also as a pivot for the barrel S. The barrel has a cog-gear on its periphery, which engages with the teeth upon the rod R, which is, for the greater part of its length, a cylindrical rack bar, and it permits the teeth to remain in en gagement, whatever the position of the plate A. The spring is so arranged, being connected at one end to the stud and at the other to the inner surface of the barrel, that when the plates A and B are pushed to the left on the rod R, the spring is wound up, and its leaction tends to force the plates constantly from the left to the right. The escapement referred to heretofore upon the right-hand side of the ma chine gives this motion imparted to the spring proper regulation. The spacing or escapement mechanism con sists of a lever, L,(represented in Figs. 1,5,6, and 9,) which works on a pivot at l. The short end engages with the under side of the rack upon the rod R, and forms part of the escapement. A spring, V, throws the long ol' forward end of the lever I tap and the short or rear end down out of the notch in the rack. The screw l is also the fulcrum of a short lever, Y, which is connected to L by a screw in front of the pivot, and on Which is fixed a spring-arm, X, attacled thereto at the forward end. The spring X, when not compressed, stands off a little distance from the lever Y, and when it is down engages with the teeth upon the rod R. On a stud fixed to the lever Y is a stop, W, which limits the lateral movement of the spring X. The Stop is pivoted in the stud, and one face is cut away more than the other, so that when turned with one side to the spring X movement of the spring over one notch is permitted, and when the other side is turned movement of two notches. It will be understood that the level Y does not engage With the lack, and that the spring S is brought into engagement with the rack on the upper side the instant the lever L is disengaged below. It will thus be seen that when the forward end of the lever Y is depressed the spring X is lifted out of the notch and springs laterally to the right over one or two notches, as the case may be. When pressure is removed from the lever L the spring V throws the rear end dowia, thus throwing the lower lever, L, out of gear and the spring into gear, when the pressure of the spring S, which must always be greater than the resistance offered by the Spring X, moves the plates one or two notches to the right, according to the motion permit ted to the spring X. Thumb-pieces ly', the former fixed to the lever L and the latter to the lever Y, afford means by which the es capement may be released from the rod R, and all this part of the apparatus moved to the left. This is effected by grasping the pieces ly' between the thumb and the fingers and press ing them together, and then forcing the plates to the left. Other mechanism may be used to regulate the distance of movement of the spring. Motion is imparted to the lever L, either directly by the application of the hand or finger-piece 20, or, by the depression of the plate A, a small stud, 22, which strikes upon the lever and depresses it with the depression of the said plate. Upon the rear end of the light-handl side piece of the plate A is a bev eled stud, 12, which strikes the spur upon the arm R and rings the bell, as heretofore ex plained. The lower end of the spur h is hinged, as shown at 24, to permit the free movement of the stud in the opposite direction. On the left-hand side piece of the plate B is a pointer, 35, which serves to indicate upon the graduated side of the bar R the position of the printing mechanism. It will thus be see that the spacing opera tion is automatically accomplished by the movement of the arm which carries the pointer and which effects the printing, and that the whole is done simultaneously. The print il)g may be at any time seen by lifting the plate B, and the inside mechanism may be at any time examined by loosening the catch be tween A and B and raising the plate A. Having thus described my invention, what I claim is 1. In a type-writing machine, a plate, A, adapted to move intermittently, a type-form attached thereto and movable to bring any given lette into alignment, and mechanism, substantially as described, for moving said - plate and type-form, Substantially as described. 2. In a type-writing machine, an elastic type fol'1), ill colnbillation with a plate having an I 25 opening thereill, said form being movable to bring any given letter into alignment with the Opening, and pel'initting any given letter to be pressed by a suitable plunger upon the paper through the openings. 3. The combination of the movable type form, the plate having opening therein, the 7 o OO IOS I IO IIS

10 O 3O 35 ink-cushion, and mechanism for pressing the plate A, hinged thereon, and the barrel pivoted 45 type upon the ink-cushion and paper, substan on said plate, and provided with a spring, the tially as described. said barrel having cogs to mesh with the 4. The combination of the elastic type-form, teeth upon the rod, whereby vertical motion the plate having an opening therein, and the is permitted to said plate without interfering stud J. 5. A vertically-movable plate, A, provided With an index-plate upon its upper surface, in combination with a type-form attached to its under side and movable thereon to bring any given letter into alignment, mechanism for moving said type-form and for directing said movement in connection with said index plate, and means, substantially as described, for pressing the type upon the paper by the depression of said plate. 6. The hinged plate A, carrying stud J, having a movable type-form carried upon its under surface and an index - plate upon its upper, in combination with an arm, P, connect ed to said type-form, and adapted, by means substantially as described, in connection with the index - plate, to bring any given letter into alignment, and also adapted to depress said plate A and force the type upon the paper, substantially as described. 7. In combination with the type-form and with the plate A, the link mechanism H. H. and M M and the intermediate frame, K, sub stantially as described. - S. The combination of the plates A and B on the rod R, and adapted to slide thereon, said plates carrying the printing mechanism, and operating substantially as described. 9. The combination of plates A and B, the upper carrying the movable type-form, and having a spring between said plates, substan tially as described. 10. The combination of the independently. hinged plates A and B, rod R, and spacing mechanism, operated by the movement of the upper plate, substantially as described. II. In combination, the rod R, having a cy lindrical surface and teeth, as described, the with the action of the spring, substantially as described. 12. The combination of the adjustable bar N of the plate B and the barg, substantially as described. 13. The combination of the levers L and Y, and the spring X with its adjustable stop, substantially as described. 14. The combination of a movable flexible type-form, the hinged perforated plate B, the barg, roller a, and spring-clip b, said roller and clip being arranged in front of the barg, whereby the plate B may be lifted and the paper removed, substantially as described. 15. In a type-writer, an elastic type-plate, in combination with a platen and with means for bringing the letters on said plate into align ment, and means for pressing said letters upon the paper, substantially as described. 16. An elastic type-form, in combination with a rigid frame fixed to the edge of said type-form, and adapted, by means substan tially as described, to be used in connection with the moving mechanism and a perforated inking-plate of the type-writer, substantially as described. 17. The combination, with the feed-roller a, of the clip b, pivoted independently of the roller, and adapted to press upon it to hold the paper, and also adapted to be raised from the roller to admit the paper, substantially as described. Intestimony whereof I have signed my name to this specification in the presence of two sub scribing Witnesses. THOS. HALL, Witnesses: E. L. HuTCHINSON, T. M. FOOTE

(No Model.) 2. Sheets-Sheet 1.

(No Model.) 2. Sheets-Sheet 1. D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS, No. 429,629, Patented June 10, 1890. (No Model.) 2. Sheets-Sheet 2, D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS. No. 429,629,

(No Model.) 2. Sheets-Sheet 1. D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS, No. 429,629, Patented June 10, 1890. (No Model.) 2. Sheets-Sheet 2, D., JOHNSON, GRASS RECEIVER FOR LAWN MOWERS. No. 429,629,

A. J. BRADLEY. No. 781,124, Witnesses. r Inventor:2.É.-2, PATENTED JAN, 31, 1905, 47-acre. By C2. 6.P 7 &nd) Attorneys, DRAFTSMAN's PRINTING MACHINE,

No. 781,124, A. J. BRADLEY. DRAFTSMAN's PRINTING MACHINE, APPLICATION FILED NOW, 10, 1903, PATENTED JAN, 31, 1905, 2 SHEETS-SHEET l. 2 V 2 Harare none r 3e3 SS ser-re SNSSNSEN A. - es Witnesses. r Inventor:2.É.-2,

No. 781,124, A. J. BRADLEY. DRAFTSMAN's PRINTING MACHINE, APPLICATION FILED NOW, 10, 1903, PATENTED JAN, 31, 1905, 2 SHEETS-SHEET l. 2 V 2 Harare none r 3e3 SS ser-re SNSSNSEN A. - es Witnesses. r Inventor:2.É.-2,

4/ /hoe 2eceolónzee-zee-ee. E 6 Ée, S. 2&772zz, z/7%zz. J422/s, Feb. 22, s. MANDL 2,108,866. Avezzr. Filed April 17, Sheets-Sheet l. 2.

Feb. 22, 1938. s. MANDL SOCKET WRENCH Filed April 17, 1936 2 Sheets-Sheet l. Se E 6 Ée, S. 2.72 N NS s Na w Avezzr. 2&772zz, z/7%zz 4/ /hoe 2eceolónzee-zee-ee J422/s, Feb. 22, 1938. S. MAND SOCKET WRENCH

Feb. 22, 1938. s. MANDL SOCKET WRENCH Filed April 17, 1936 2 Sheets-Sheet l. Se E 6 Ée, S. 2.72 N NS s Na w Avezzr. 2&772zz, z/7%zz 4/ /hoe 2eceolónzee-zee-ee J422/s, Feb. 22, 1938. S. MAND SOCKET WRENCH

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, (Applicatioxg filed Jan. 27, 1899.

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, 81.0. (Applicatioxg filed Jan. 27, 1899.) ' (No Model.) 2 s_heets-sheet l. ó» y@ gw/q. Nn. 635,225.. f Patentad

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, 81.0. (Applicatioxg filed Jan. 27, 1899.) ' (No Model.) 2 s_heets-sheet l. ó» y@ gw/q. Nn. 635,225.. f Patentad

No. 394,668, Patented Dec. 18, 1888.

(No Model.) 3 Sheets-Sheet 1. H. S. S. WAT KIN. ANEROID BAROMETER, No. 394,668, Patented Dec. 18, 1888. u D. L. E. 5. N. perers, Photo-lithographer, Washington, D.C. No Model.) No. 394,668 3 Sheets-Sheet

(No Model.) 3 Sheets-Sheet 1. H. S. S. WAT KIN. ANEROID BAROMETER, No. 394,668, Patented Dec. 18, 1888. u D. L. E. 5. N. perers, Photo-lithographer, Washington, D.C. No Model.) No. 394,668 3 Sheets-Sheet

United States Patent 19 Couture et al.

United States Patent 19 Couture et al. 54 VEGETABLE PEELINGAPPARATUS 76 Inventors: Fernand Couture; René Allard, both of 2350 Edouard-Montpetit Blvd., Montreal, Quebec, Canada, H3T 1J4 21 Appl. No.: 805,985

United States Patent 19 Couture et al. 54 VEGETABLE PEELINGAPPARATUS 76 Inventors: Fernand Couture; René Allard, both of 2350 Edouard-Montpetit Blvd., Montreal, Quebec, Canada, H3T 1J4 21 Appl. No.: 805,985

No. 622,774. Patented Apr. 1, 1899.

No. 622,774. Patented Apr. 1, 1899. J. M. MACLUCH. METHOD OF MANUFACTURING INDIA RUBBER OR OTHER ENDLESS BANDS OR STRIPS. (Application filed Oct. 4, 1898. (No Model.) 3 Sheets-Sheet 1. tenorris Peters

No. 622,774. Patented Apr. 1, 1899. J. M. MACLUCH. METHOD OF MANUFACTURING INDIA RUBBER OR OTHER ENDLESS BANDS OR STRIPS. (Application filed Oct. 4, 1898. (No Model.) 3 Sheets-Sheet 1. tenorris Peters

No. 752,792. PATENTED FEB, 23, 1904, H, MOYA, TYPE WRITING MACHINE, APPLICATION FLED JAN. 10, RO MODEL, 7 SHEETS-SHEET l. Zz 23 sir H.

No. 752,792. PATENTED FEB, 23, 1904, H, MOYA, TYPE WRITING MACHINE, APPLICATION FLED JAN. 10, 1902. RO MODEL, 7 SHEETS-SHEET l. Zz 23 sir H. - - - - - - - - M. ------------ 27 I r -----------------a -

No. 752,792. PATENTED FEB, 23, 1904, H, MOYA, TYPE WRITING MACHINE, APPLICATION FLED JAN. 10, 1902. RO MODEL, 7 SHEETS-SHEET l. Zz 23 sir H. - - - - - - - - M. ------------ 27 I r -----------------a -

April 10, L. MALICAY 2,373,584 COCOANUT CUTTING MACHINE. HEDEar N--- acacases. \ Zeanaze A? a leay. 20%ive s?alafa.

April 10, 1945. L. MALICAY 2,373,584 COCOANUT CUTTING MACHINE Filed Sept. 23, 1943 4 Sheets-Sheet l Y HEDEar N--- acacases \ Zeanaze A? a leay 20%ive s?alafa. April 10, 1945. L. MACAY 2,373,584 COCOANUT

April 10, 1945. L. MALICAY 2,373,584 COCOANUT CUTTING MACHINE Filed Sept. 23, 1943 4 Sheets-Sheet l Y HEDEar N--- acacases \ Zeanaze A? a leay 20%ive s?alafa. April 10, 1945. L. MACAY 2,373,584 COCOANUT

Seal. e/ IOI - N3ssersys (RH S. O. CZazazzee c1722. May 14, c. J. Rio 2,200,896 HOIST PULLEY AND ROPE GRIPPER.

May 14, 19. c. J. Rio 2,0,896 HOIST PULLEY AND ROPE GRIPPER Filed Sept. 13, 1939 2 Sheets-Sheet l S. SAYS SaN7 IOI - N3ssersys (RH S. O A 7477 NSSK A ZOA to R3N Seal S YaYaas 4. S A- Z-A-Z NYP 2 SARSSSYO

May 14, 19. c. J. Rio 2,0,896 HOIST PULLEY AND ROPE GRIPPER Filed Sept. 13, 1939 2 Sheets-Sheet l S. SAYS SaN7 IOI - N3ssersys (RH S. O A 7477 NSSK A ZOA to R3N Seal S YaYaas 4. S A- Z-A-Z NYP 2 SARSSSYO

1,502, Boaz, only 22, MARIONETTE M. M. DONDO 27 A/ %- - IA WEATOR

only 22, 1924. t M. M. DONDO MARIONETTE Filed July 1, 1922 3. Sheets-Sheet l - IA WEATOR s alfull-.. 27 Boaz, 27 A/ %- Y.f iii).* d July 22, 1924 e M. M. DONDO MARIONETTE Filled July l, 1922 3 Sheets-Sheet

only 22, 1924. t M. M. DONDO MARIONETTE Filed July 1, 1922 3. Sheets-Sheet l - IA WEATOR s alfull-.. 27 Boaz, 27 A/ %- Y.f iii).* d July 22, 1924 e M. M. DONDO MARIONETTE Filled July l, 1922 3 Sheets-Sheet

====== ==--~~~~). % 7 3,329,240. July 4, , FRANK STUART HARwooD ATTORNEYS F. S. HARWOOD EA ELEWATOR ROLLER GUIDE ASSEMBLY. 2.

July 4, 1967 Filed Jan. 7, 1966 F. S. HARWOOD EA ELEWATOR ROLLER GUIDE ASSEMBLY 3,329,2 2. Sheets-Sheet ====== ==--~~~~). \\ 42, INVENTORS FRANK STUART HARwooD CAR. T. PRUCHA HEI NZ DORST BYa. % 7 ATTORNEYS

July 4, 1967 Filed Jan. 7, 1966 F. S. HARWOOD EA ELEWATOR ROLLER GUIDE ASSEMBLY 3,329,2 2. Sheets-Sheet ====== ==--~~~~). \\ 42, INVENTORS FRANK STUART HARwooD CAR. T. PRUCHA HEI NZ DORST BYa. % 7 ATTORNEYS

No. 648,930. Patented May 8, H. J. DOUGHTY. - MANUFACTURE OF CONTINUOUs TUBINGS OR COVERINGS OF RUBBER.

No. 648,930. Patented May 8, 1900. H. J. DOUGHTY. - MANUFACTURE OF CONTINUOUs TUBINGS OR COVERINGS OF RUBBER. (Application filed Dec. 17, 1898. (No Model.) 3 sheets-sheet. Z5 ZB Nissa as us S3) aaaaaaaaaaaaaaaaaaaaaaaa.

No. 648,930. Patented May 8, 1900. H. J. DOUGHTY. - MANUFACTURE OF CONTINUOUs TUBINGS OR COVERINGS OF RUBBER. (Application filed Dec. 17, 1898. (No Model.) 3 sheets-sheet. Z5 ZB Nissa as us S3) aaaaaaaaaaaaaaaaaaaaaaaa.

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE. . _ LAWN MOWER. N0.'554,081. Patented Feb. 4, $5 9; Em ;! \ g/ F

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE.. _ LAWN MOWER. N0.'554,081. Patented Feb. 4, 1896. H $5 9; Em ;! \ g/ F % (No Model.) E. W. MCGUIRE. LAWN MOWER. a" Sheets-Sheet 2, No. 554,081. PéJtentedI'eb.

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE.. _ LAWN MOWER. N0.'554,081. Patented Feb. 4, 1896. H $5 9; Em ;! \ g/ F % (No Model.) E. W. MCGUIRE. LAWN MOWER. a" Sheets-Sheet 2, No. 554,081. PéJtentedI'eb.

Z3: wa 2%ist a? 4,822. rizzesses 3.5L ES. K. N. 944,489. Patented Dec. 28, &ANN

- B, A, INDERMAN, EDCNG ATTACHMENT FOR LUMBER JOINING MACHINES, APPLICATION FILED JUNE 1, 1909. 944,489. Patented Dec. 28, 1909. 4. SHEETS-SHEET 1. E 26&ANN assa, 3.5L ES. K. N. Z3: 3. rizzesses f 2. aza

- B, A, INDERMAN, EDCNG ATTACHMENT FOR LUMBER JOINING MACHINES, APPLICATION FILED JUNE 1, 1909. 944,489. Patented Dec. 28, 1909. 4. SHEETS-SHEET 1. E 26&ANN assa, 3.5L ES. K. N. Z3: 3. rizzesses f 2. aza

(No Model.) 8. Sheets-Sheet,, H. D., MENTZEL, MECHANICAL MOVEMENT, No. 447,964, Patented Mar, 10, 1891, (. ) 8-line K22,

(No Model.) 8. Sheets-Sheet,, H. D., MENTZEL, MECHANICAL MOVEMENT, No. 447,964, Patented Mar, 10, 1891, ry (. ) 8-line h -VV TNESSES - INN/ENT OR K22, 2.2 2.2. /-9a/ 34 - a (No Mode.) 8 Sheets-Sheet 2.

(No Model.) 8. Sheets-Sheet,, H. D., MENTZEL, MECHANICAL MOVEMENT, No. 447,964, Patented Mar, 10, 1891, ry (. ) 8-line h -VV TNESSES - INN/ENT OR K22, 2.2 2.2. /-9a/ 34 - a (No Mode.) 8 Sheets-Sheet 2.

Nov. 14, 1967 D. PREston 3,352,553 CONTINUOUS FORMS FOLDER MACHINE

Nov. 14, 1967 D. PREston CONTINUOUS FORMS FOLDER MACHINE Filed Oct. 14, 1965 4 Sheets-Sheet Nov. 14, 1967 D. PRESTON CONTINUOUS FORMS FOLDER MACHINE Filed Oct. l4, 1965 4. Sheets-Sheet 2 t -O.S. s t ae

Nov. 14, 1967 D. PREston CONTINUOUS FORMS FOLDER MACHINE Filed Oct. 14, 1965 4 Sheets-Sheet Nov. 14, 1967 D. PRESTON CONTINUOUS FORMS FOLDER MACHINE Filed Oct. l4, 1965 4. Sheets-Sheet 2 t -O.S. s t ae

A. BURGESS. FOLDING MAGAZINE GUN. No. 524,800.

(No Model.) A. BURGESS. FOLDING MAGAZINE GUN. 2 Sheets-Sheet 1. No. 524,800. Patented Aug. 21, 18-94. 5%?., gllfl'll'l'lllllll 7/////////A (No Model.) No. 524,800. F 0 L AM UM RA G GA Z Sm E SE.G U. N..2.S

(No Model.) A. BURGESS. FOLDING MAGAZINE GUN. 2 Sheets-Sheet 1. No. 524,800. Patented Aug. 21, 18-94. 5%?., gllfl'll'l'lllllll 7/////////A (No Model.) No. 524,800. F 0 L AM UM RA G GA Z Sm E SE.G U. N..2.S

Nov. 18, S. P. Rockwell HARDNESS TESTING MACHINE 1, Filed Sept. 2 Sheets-Sheet II. lill, INVENTOR.

Nov. 18, 1924. S. P. Rockwell HARDNESS TESTING MACHINE Filed Sept. lill, 199 1,16.7 2 Sheets-Sheet II INVENTOR. Nov. 8, 1924. 1,16,7 S, FP, ROCKWELL HARDNESS TESTING MACHINE Filed Sept. 1, 1919 2 Sheets-Sheet

Nov. 18, 1924. S. P. Rockwell HARDNESS TESTING MACHINE Filed Sept. lill, 199 1,16.7 2 Sheets-Sheet II INVENTOR. Nov. 8, 1924. 1,16,7 S, FP, ROCKWELL HARDNESS TESTING MACHINE Filed Sept. 1, 1919 2 Sheets-Sheet

April 1, ,488,659 J. C. ABEL ET AL WALK OVER SEAT. fill. É 2 N N PPAP //W/AW7OAS. casez/24/7zee. a 774 A2Z2 A/2//av/22/ a 77OAMAY

April 1, 1924. 1,488,659 fill. WALK OVER SEAT PS3 Feb: 5. 1921 3. Sheets-Sheet l É 2 a e s 2 10 N N PPAP 2 //W/AW7OAS casez/24/7zee a 774 A2Z2 A/2//av/22/ a 77OAMAY April 1, 1924. WALK OWER SEAT Filed

April 1, 1924. 1,488,659 fill. WALK OVER SEAT PS3 Feb: 5. 1921 3. Sheets-Sheet l É 2 a e s 2 10 N N PPAP 2 //W/AW7OAS casez/24/7zee a 774 A2Z2 A/2//av/22/ a 77OAMAY April 1, 1924. WALK OWER SEAT Filed

Patented July 18, 1899.

No. 629,267. ( No Model.) O. C. MOTE. DEVCE FOR HANGING TOBACCO. (Application filed Feb. 0, 1899. Patented July 18, 1899. 2 Sheets-Sheet.. s-perers co. F icro-3-0 WASHINGTCN, 3, c. - No. 629,267 --- Patented

No. 629,267. ( No Model.) O. C. MOTE. DEVCE FOR HANGING TOBACCO. (Application filed Feb. 0, 1899. Patented July 18, 1899. 2 Sheets-Sheet.. s-perers co. F icro-3-0 WASHINGTCN, 3, c. - No. 629,267 --- Patented

April 5, C. KEMP

April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2 Sheets-Sheet l April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2. Sheets-Sheet 2 ATTORNEYS. Patented Apr., 1938 2,113,02

April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2 Sheets-Sheet l April, 1938. C. KEMP 2,113,02 BOX MAKING MACHINE Filed Nov., 1936 2. Sheets-Sheet 2 ATTORNEYS. Patented Apr., 1938 2,113,02

927,055, 2: (azzs. 220&a/z/ZAZazezzey. A. Czeezye/Zorce/Z/7. 6 Z70®a/2s. W. A. KRAEMER & G, F. HOWELL, JR, 4 SHEETS-SHEET. 1.

927,055, W. A. KRAEMER & G, F. HOWELL, JR, PAPER WENDING MACHINE, APPLICATION FILED JUNE 10, 1907, 4 SHEETS-SHEET. 1. 6 Z70®a/2s. 220&a/z/ZAZazezzey A. Czeezye/Zorce/Z/7. 2: (azzs 927,055, W. A. KRAEMER

927,055, W. A. KRAEMER & G, F. HOWELL, JR, PAPER WENDING MACHINE, APPLICATION FILED JUNE 10, 1907, 4 SHEETS-SHEET. 1. 6 Z70®a/2s. 220&a/z/ZAZazezzey A. Czeezye/Zorce/Z/7. 2: (azzs 927,055, W. A. KRAEMER

United States Patent (19) Over et al.

United States Patent (19) Over et al. 54). CAPPING HEAD AND MACHINE 75) Inventors: David J. Over; Daniel J. Burkhardt, both of Richmond, Ind. 73) Assignee: Aluminum Company of America, Pittsburgh, Pa.

United States Patent (19) Over et al. 54). CAPPING HEAD AND MACHINE 75) Inventors: David J. Over; Daniel J. Burkhardt, both of Richmond, Ind. 73) Assignee: Aluminum Company of America, Pittsburgh, Pa.

J. C. BARR, INDICATOR LOCK, No. 426,097. Patented Apr. 22, 1890, 222 AN-8. S 2 P 9. it? SEH) sts

(No Model.) J. C. BARR, INDICATOR LOCK, 2 Sheets-Sheet 1. No. 426,097. Patented Apr. 22, 1890, 222 AN-8 Y AN SEH) S 2 P 9. it? sts (No Model.) 2. Sheets-Sheet 2. J. C. BARR, INDICATOR LOCK, No. 426,097,

(No Model.) J. C. BARR, INDICATOR LOCK, 2 Sheets-Sheet 1. No. 426,097. Patented Apr. 22, 1890, 222 AN-8 Y AN SEH) S 2 P 9. it? sts (No Model.) 2. Sheets-Sheet 2. J. C. BARR, INDICATOR LOCK, No. 426,097,

(No Model.) 3. Sheets. Sheet

(No Model.) 3. Sheets Sheet 2%? % No. 636,196. (No Model.) A. BURGESS. A UT0 ATIC GUN. (Application filed Feb. 25, 1896.) Patented Oct. 31, 1899. 3. Sheets Sheet 2. V}žŽ7zésse 5. No. 636,196, (RO Rode?.)

(No Model.) 3. Sheets Sheet 2%? % No. 636,196. (No Model.) A. BURGESS. A UT0 ATIC GUN. (Application filed Feb. 25, 1896.) Patented Oct. 31, 1899. 3. Sheets Sheet 2. V}žŽ7zésse 5. No. 636,196, (RO Rode?.)

Smith-Corona HOW TO USE PORTABLE TYPEWRITERS FLOATING SHIFT MODELS. L C Smith & Corona Typewriters Inc 701 E Washington St Syracuse N Y

HOW TO USE Smith-Corona PORTABLE TYPEWRITERS FLOATING SHIFT MODELS Printed and Published by L C Smith & Corona Typewriters Inc 701 E Washington St Syracuse N Y ' The serial number, stamped 0n the inner

HOW TO USE Smith-Corona PORTABLE TYPEWRITERS FLOATING SHIFT MODELS Printed and Published by L C Smith & Corona Typewriters Inc 701 E Washington St Syracuse N Y ' The serial number, stamped 0n the inner

May 14, ,792,253 G. N. BLISS EGG LIFTER. Filed April 27, l Sheets-Sheet. NVENTOR. 422%a Mazass. by/2.yzzell. ATORNEY

May 14, 197 Filed April 27, l93 G. N. BLISS EGG LIFTER 2 Sheets-Sheet. f NVENTOR 422%a Mazass by/2.yzzell. ATORNEY May 14, 197 Filed April 27, 193 G. N. BLISS EGG LIFTER 2. Sheets-Sheet 2 BY NVENTOR 426.a6a

May 14, 197 Filed April 27, l93 G. N. BLISS EGG LIFTER 2 Sheets-Sheet. f NVENTOR 422%a Mazass by/2.yzzell. ATORNEY May 14, 197 Filed April 27, 193 G. N. BLISS EGG LIFTER 2. Sheets-Sheet 2 BY NVENTOR 426.a6a

UNITED STATES PATENT OFFICE.

I10 20 25 30 35 40 45 50 55 UNITED STATES PATENT OFFICE. JOHN ERICSSON, OF LONDON, ENGLAND. PROPELLING STEAM VESSELS. Specification of Letters Patent No. 588,.dated February 1, 1838. To all vhon, it may

I10 20 25 30 35 40 45 50 55 UNITED STATES PATENT OFFICE. JOHN ERICSSON, OF LONDON, ENGLAND. PROPELLING STEAM VESSELS. Specification of Letters Patent No. 588,.dated February 1, 1838. To all vhon, it may

(2%22a. 2%. 4é. c2ate. 4-u-C MACHINE FOR FORMING GR00VES OR FLUTES IN TWIST DRILLS AND THE LIKE, H. WRIGHT, / M W AM 7-0 y :

H. WRIGHT, MACHINE FOR FORMING GR00VES OR FLUTES IN TWIST DRILLS AND THE LIKE, APPLICATION FLED AUG, 4, 1917, 1,846,928. Patented July 20, 1920. 5. SheeTS-SHEET 1. c2ate / M W AM 7-0 y : w (2%22a - 4-u-C

H. WRIGHT, MACHINE FOR FORMING GR00VES OR FLUTES IN TWIST DRILLS AND THE LIKE, APPLICATION FLED AUG, 4, 1917, 1,846,928. Patented July 20, 1920. 5. SheeTS-SHEET 1. c2ate / M W AM 7-0 y : w (2%22a - 4-u-C

July 21, J. W. BATE 1,815,885 SCREW JACK

July 21, 1931. J. W. BATE 1,81,88 Filed Jan. 3, 1927 of 77 Zzz, II -2. 72 Sim r Mr.SIN 4. N 4. & NISINSYN2 72 SS 16 y2) W 7. Šá N 2. Sheets-Sheet l 3 A. % 76 --------- % % 3. W 2 m % % 3. - - - --------

July 21, 1931. J. W. BATE 1,81,88 Filed Jan. 3, 1927 of 77 Zzz, II -2. 72 Sim r Mr.SIN 4. N 4. & NISINSYN2 72 SS 16 y2) W 7. Šá N 2. Sheets-Sheet l 3 A. % 76 --------- % % 3. W 2 m % % 3. - - - --------

Hsu (45) Date of Patent: Jul. 27, PICTURE FRAME Primary Examiner-Kenneth J. Dorner. Assistant Examiner-Brian K. Green

III United States Patent (19) 11) US005230172A Patent Number: 5,230,172 Hsu (45) Date of Patent: Jul. 27, 1993 54 PICTURE FRAME Primary Examiner-Kenneth J. Dorner o Assistant Examiner-Brian K. Green 76)

III United States Patent (19) 11) US005230172A Patent Number: 5,230,172 Hsu (45) Date of Patent: Jul. 27, 1993 54 PICTURE FRAME Primary Examiner-Kenneth J. Dorner o Assistant Examiner-Brian K. Green 76)

3,405,466 DESK INDEXING IDE WECE. Filed Aug. 18, Sheets-Sheet l. mp=aeg A022 NVENTORS. RICHARD McFADYEN JAMES H. G LTZOW AT TORNEYS

Oct. 15, 1968 R. MCFADYEN, ET AL DESK INDEXING IDE WECE Filed Aug. 18, 1966 5 Sheets-Sheet l mp=aeg A022 NVENTORS RICHARD McFADYEN JAMES H. G LTZOW SY AT TORNEYS Oct. 15, 1968 R. MCFADYEN ET AL- DESK INDEXING

Oct. 15, 1968 R. MCFADYEN, ET AL DESK INDEXING IDE WECE Filed Aug. 18, 1966 5 Sheets-Sheet l mp=aeg A022 NVENTORS RICHARD McFADYEN JAMES H. G LTZOW SY AT TORNEYS Oct. 15, 1968 R. MCFADYEN ET AL- DESK INDEXING

Dec. 15, W. A. MATHESON 1,836,981 MASSAGING AND EXERCISING APPARATUS. of7eavezza27. z0/z77es 5." 4-2/64/ (M26a77% Azazesozz 2421% /72%

Dec. 15, 1931. W. A. MATHESON 1,836,981 MASSAGING AND EXERCISING APPARATUS Filed Aug. 8, 1927 4. Sheets-Sheet z0/z77es 5." 4-2/64/ of7eavezza27 (M26a77% Azazesozz 2421% /72% Dec. 15, 1931. W. A. MATHESON

Dec. 15, 1931. W. A. MATHESON 1,836,981 MASSAGING AND EXERCISING APPARATUS Filed Aug. 8, 1927 4. Sheets-Sheet z0/z77es 5." 4-2/64/ of7eavezza27 (M26a77% Azazesozz 2421% /72% Dec. 15, 1931. W. A. MATHESON

United States Patent (19)

United States Patent (19) Negley 54 DRILL GRINDER 75) Inventor: Marvin C. Negley, Clarinda, Iowa 73) Assignee: Lisle Corporation, Clarinda, Iowa 22 Filed: Oct. 29, 1974 (21) Appl. No.: 518,757 (52) U.S.

United States Patent (19) Negley 54 DRILL GRINDER 75) Inventor: Marvin C. Negley, Clarinda, Iowa 73) Assignee: Lisle Corporation, Clarinda, Iowa 22 Filed: Oct. 29, 1974 (21) Appl. No.: 518,757 (52) U.S.

Oct. 19, 1971 R. F. ANDERSON E.T A. 3,613,151 HINGE CONSTRUCTION. Sed. a1sza N5 V. az-s W 7 ree-?ex Caeta' toen &

Oct. 19, 1971 R. F. ANDERSON E.T A. 3,613,11 Filed June 27, 1969 3. Sheets-Sheet Sed a1sza N V 22 az-s W 7 ree-?ex Caeta' toen & g Oct. 19, 1971 R. F. ANDERson ET AL 3,613,11 Filed June 27, 1969 3. Sheets-Sheet

Oct. 19, 1971 R. F. ANDERSON E.T A. 3,613,11 Filed June 27, 1969 3. Sheets-Sheet Sed a1sza N V 22 az-s W 7 ree-?ex Caeta' toen & g Oct. 19, 1971 R. F. ANDERson ET AL 3,613,11 Filed June 27, 1969 3. Sheets-Sheet

SERVICE MANUAL AND PARTSLIST

SERVICE MANUAL AND PARTSLIST Next 20 CONTENTS WHAT TO DO WHEN... 1~3 SERVICE ACCESS FACE COVER... 4 TOP COVER... 4 BASE COVER... 5 REAR COVER... 6 FRONT COVER... 7 MECHANICAL ADJUSTMENT NEEDLE THREAD TENSION...

SERVICE MANUAL AND PARTSLIST Next 20 CONTENTS WHAT TO DO WHEN... 1~3 SERVICE ACCESS FACE COVER... 4 TOP COVER... 4 BASE COVER... 5 REAR COVER... 6 FRONT COVER... 7 MECHANICAL ADJUSTMENT NEEDLE THREAD TENSION...

United States Patent [15] 3,650,496 Svensson (45) Mar. 21, 1972

![United States Patent [15] 3,650,496 Svensson (45) Mar. 21, 1972 United States Patent [15] 3,650,496 Svensson (45) Mar. 21, 1972](/thumbs/91/105347464.jpg) United States Patent [15] 3,650,496 Svensson (45) Mar. 21, 1972 54. FOLDING FNS FOR MESSELES 3,273,500 9/1966 Kongelbeck... 244/3.28 (72) Inventor: Nils-Åke Birger Svensson, Karlskoga, Primary Examiner-Verlin

United States Patent [15] 3,650,496 Svensson (45) Mar. 21, 1972 54. FOLDING FNS FOR MESSELES 3,273,500 9/1966 Kongelbeck... 244/3.28 (72) Inventor: Nils-Åke Birger Svensson, Karlskoga, Primary Examiner-Verlin

2x2 EARCEPOST APPROVED IMPORTANT SYSA NEX2 N - May 21, 1963 T, A, SULKE 3, (ZW, Filed Aug. 28, 196l AR MAIL RUBBER STAMP DEVICE ATTORNEYS

May 21, 1963 T, A, SULKE 3,0904 RUBBER STAMP DEVICE Filed Aug. 28, 196l AR MAIL EARCEPOST APPROVED IMPORTANT 22 SN &KNS SYSA (ZW, SS NEX2 N - 2x2 S&N 2. A Ya Ya Y A SSSSSSSSSS INVENTOR Thomas Sulkie ATTORNEYS

May 21, 1963 T, A, SULKE 3,0904 RUBBER STAMP DEVICE Filed Aug. 28, 196l AR MAIL EARCEPOST APPROVED IMPORTANT 22 SN &KNS SYSA (ZW, SS NEX2 N - 2x2 S&N 2. A Ya Ya Y A SSSSSSSSSS INVENTOR Thomas Sulkie ATTORNEYS

"62/.62.6 S3 ( A/27 AAZZZ, at a fic-12 SS SN IN June 26, 1962 H. W. KUP 3,040,420. NN TÉ 2, a87-zé g-g2 SNAP RING PLIERS

June 26, 1962 H. W. KUP 3,040,420 SNAP RING PLIERS Filed Jan. 12, l960 2. Sheets-Sheet l AZY B 4f 32 30 NN TÉ 2, a87-zé g-g2 S3 (330 25 SS SN IN 76-. 26. at 72 62 44 a fic-12 4/7 47 32. 47 Saa1 Z 7 AZ670

June 26, 1962 H. W. KUP 3,040,420 SNAP RING PLIERS Filed Jan. 12, l960 2. Sheets-Sheet l AZY B 4f 32 30 NN TÉ 2, a87-zé g-g2 S3 (330 25 SS SN IN 76-. 26. at 72 62 44 a fic-12 4/7 47 32. 47 Saa1 Z 7 AZ670

J. H. BOURGON WINDOW REGULATOR INVENTOR. VO5AA/ AyasoA6GO/y

Feb. 8, 1927. J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 Sheets-Sheet l INVENTOR VO5AA/ AyasoA6GO/y BY Ed Feb. 8, 1927.... J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 2 Sheets-Sheet 2 N

Feb. 8, 1927. J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 Sheets-Sheet l INVENTOR VO5AA/ AyasoA6GO/y BY Ed Feb. 8, 1927.... J. H. BOURGON WINDOW REGULATOR Filed June 28, 1923 2 Sheets-Sheet 2 N

July 13, R. J. Morrow

July 13, 1937. R. J. Morrow MINIATURE THEATER Filed May 14, 1936 2. Sheets-Sheet 1 1 4 ANVENTOR 4% BY E. July 13, 1937. R. J. Morrow..... MINIATURE THEATER.. Filed May 14, 1936 2. Sheets-Sheet 2 s S t

July 13, 1937. R. J. Morrow MINIATURE THEATER Filed May 14, 1936 2. Sheets-Sheet 1 1 4 ANVENTOR 4% BY E. July 13, 1937. R. J. Morrow..... MINIATURE THEATER.. Filed May 14, 1936 2. Sheets-Sheet 2 s S t

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 20120047754A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0047754 A1 Schmitt (43) Pub. Date: Mar. 1, 2012 (54) ELECTRICSHAVER (52) U.S. Cl.... 30/527 (57) ABSTRACT

US 20120047754A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0047754 A1 Schmitt (43) Pub. Date: Mar. 1, 2012 (54) ELECTRICSHAVER (52) U.S. Cl.... 30/527 (57) ABSTRACT

Feb. 12, 1952 E. ALTMAN 2,585,073 PEACH PITTING MACHINE INVENTOR. BY 6%au-v62. ATTORNEYS.

Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet INVENTOR BY 6%au-v62. ATTORNEYS. Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet 2 /6- /2 72.2. Zsz27Z ZZZZZZZZ,

Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet INVENTOR BY 6%au-v62. ATTORNEYS. Feb. 12, 1952 E. ALTMAN 2,585,073 Filed Feb. 9, 1949 5 Sheets-Sheet 2 /6- /2 72.2. Zsz27Z ZZZZZZZZ,

United States Patent (19) (11) 3,865,005 Carree (45) Feb. 11, 1975

United States Patent (19) (11) 3,865,005 Carree (45) Feb. 11, 1975 54) WIND MUSICAL INSTRUMENT 2,560,083 7/1951 Bullock... 84/385 75) Inventor: Robert Victor Carree, Mantes-la-Ville, France Primary Examiner-Lawrence

United States Patent (19) (11) 3,865,005 Carree (45) Feb. 11, 1975 54) WIND MUSICAL INSTRUMENT 2,560,083 7/1951 Bullock... 84/385 75) Inventor: Robert Victor Carree, Mantes-la-Ville, France Primary Examiner-Lawrence

2,163,572. June 27, Filed Nov. 16, 1937 A. B. CROSBY ENVELOPE-STUFFING MACHINE. 3. Sheets-Sheet l

June 27, 1939. A. B. CROSBY EVELOPE-STUFFIG MACHIE Filed ov. 16, 1937 3. Sheets-Sheet l June 27, 1939. A. B. CROSBY EVELOPE-STUFFIG MACHIE Filed ov. 16, 1937 3. Sheets-Sheet 2 03% 9% o.iiiiiij?????.??ttii

June 27, 1939. A. B. CROSBY EVELOPE-STUFFIG MACHIE Filed ov. 16, 1937 3. Sheets-Sheet l June 27, 1939. A. B. CROSBY EVELOPE-STUFFIG MACHIE Filed ov. 16, 1937 3. Sheets-Sheet 2 03% 9% o.iiiiiij?????.??ttii

SERVICE MANUAL. Sewing Machine. Copyright 1976 The Singer Company Aii Rights Reserved Throughout the World *A Trademark of THE SiNGER COMPANY

1 SERVICE MANUAL SINGER Sewing Machine 121D200A Copyright 1976 The Singer Company Aii Rights Reserved Throughout the World *A Trademark of THE SiNGER COMPANY Form 21624 (876) Printed In U.S.A. LUBRICATION

1 SERVICE MANUAL SINGER Sewing Machine 121D200A Copyright 1976 The Singer Company Aii Rights Reserved Throughout the World *A Trademark of THE SiNGER COMPANY Form 21624 (876) Printed In U.S.A. LUBRICATION

(12) United States Patent (10) Patent No.: US 6,848,291 B1

USOO684.8291B1 (12) United States Patent (10) Patent No.: US 6,848,291 B1 Johnson et al. (45) Date of Patent: Feb. 1, 2005 (54) PRESS BRAKE TOOL AND TOOL HOLDER FOREIGN PATENT DOCUMENTS (75) Inventors:

USOO684.8291B1 (12) United States Patent (10) Patent No.: US 6,848,291 B1 Johnson et al. (45) Date of Patent: Feb. 1, 2005 (54) PRESS BRAKE TOOL AND TOOL HOLDER FOREIGN PATENT DOCUMENTS (75) Inventors:

, a?o-az. 2%6%/ a ZZeeve.2 (2 p. improvement in Cue-Racks for Billiar d-r00 ms. H. W. COLLENDER. Patented July 9, ' N :35.

- 3 Sheets--Sheet. H. W. COLLENDER. improvement in Cue-Racks for Billiar d-r00 ms. N 0. 123:35. Patented July 9, 1872. ' --- e t i a. A LIB 1 flat BE F. R ----------- r-m- 22 are esses. 2%6%/ a ZZeeve.2

- 3 Sheets--Sheet. H. W. COLLENDER. improvement in Cue-Racks for Billiar d-r00 ms. N 0. 123:35. Patented July 9, 1872. ' --- e t i a. A LIB 1 flat BE F. R ----------- r-m- 22 are esses. 2%6%/ a ZZeeve.2

United States Patent (19) Moore III

United States Patent (19) Moore III (54) DEVICE FOR POSITONING AN EMBRODERY HOOP 76 Inventor: Edgar F. Moore III, 4447 Old Randleman Rd., Greensboro, N.C. 27406 (21) Appl. No.: 123,340 22) Filed: Nov.

United States Patent (19) Moore III (54) DEVICE FOR POSITONING AN EMBRODERY HOOP 76 Inventor: Edgar F. Moore III, 4447 Old Randleman Rd., Greensboro, N.C. 27406 (21) Appl. No.: 123,340 22) Filed: Nov.

No. 527,742 Patented Oct. 16, 1894.

(No Model.) P. J. DEWAULT WIND REED MUSICAL INSTRUMENT, No. Patented ct. 16, 1894. INVENTR Y ATTRNEY - y UNITED STATES PATENT FFICE. PHILIP J. DEWA UILT, F DEN VER, CLR AD. WIND REED MUSICAL INSTRUMENT.

(No Model.) P. J. DEWAULT WIND REED MUSICAL INSTRUMENT, No. Patented ct. 16, 1894. INVENTR Y ATTRNEY - y UNITED STATES PATENT FFICE. PHILIP J. DEWA UILT, F DEN VER, CLR AD. WIND REED MUSICAL INSTRUMENT.

%.4-7.7% (Zé Gézvá. No. 349,343. Patented Sept. 21, W. H. ERNST. MACHINE FOR TURNING IRREGULAR FORMS. Il-77WESSES U- WWEAV7OAR. A TTORNEY.

(No Model.) 3. Sheets-Sheet 1. W. H. ERNST. MACHINE FOR TURNING IRREGULAR FORMS. No. 349,343. Patented Sept. 21, 1886. i. 2 S Il-77WESSES U- WWEAV7OAR. (Zé Gézvá %.4-7.7% A TTORNEY. (No Model.) 3 Sheets-Sheet

(No Model.) 3. Sheets-Sheet 1. W. H. ERNST. MACHINE FOR TURNING IRREGULAR FORMS. No. 349,343. Patented Sept. 21, 1886. i. 2 S Il-77WESSES U- WWEAV7OAR. (Zé Gézvá %.4-7.7% A TTORNEY. (No Model.) 3 Sheets-Sheet

Ay:44, 444-, INven TOR HARVEY R. PLUMMER. Jan. 3, 1967 H. R. PLUMMER 3,295,187. ArTws, Filed March l, Sheets-Sheet

Jan. 3, 1967 H. R. PLUMMER Filed March l, 1965 2 Sheets-Sheet INven TOR HARVEY R. PLUMMER Ay:44, 444-, 14-42--- ArTws, Jan. 3, 1967 H. R. PUMMER Filed March 1, 1965 2. Sheets-Sheet 2 INVENTOR HARVEY R.

Jan. 3, 1967 H. R. PLUMMER Filed March l, 1965 2 Sheets-Sheet INven TOR HARVEY R. PLUMMER Ay:44, 444-, 14-42--- ArTws, Jan. 3, 1967 H. R. PUMMER Filed March 1, 1965 2. Sheets-Sheet 2 INVENTOR HARVEY R.

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030085640A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0085640 A1 Chan (43) Pub. Date: May 8, 2003 (54) FOLDABLE CABINET Publication Classification (76) Inventor:

US 20030085640A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0085640 A1 Chan (43) Pub. Date: May 8, 2003 (54) FOLDABLE CABINET Publication Classification (76) Inventor:

PFAFF. rom the library of: Superior Sewing Machine & Supply LLC. Service Manual Justieranl. engi. 7.92

PFAFF 5642 Service Manual 296-12-13925 Justieranl. engi. 7.92 Notes on safety The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate training.

PFAFF 5642 Service Manual 296-12-13925 Justieranl. engi. 7.92 Notes on safety The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate training.

2. s 8 N. J. A. JOHNSON, WRENCH, application FILED MAR, 23, 92 Patented Apr. 18, s 9 A.L. 2 she ETS-SHEET 2. 8 S8.

J. A. JOHNSON, WRENCH, 1. 413 121 application FILED MAR, 23, 92 Patented Apr. 1, 1922. s 9 A.L. 2 she ETS-SHEET 2. exxx: XXXXXXX) XX XXXXX. (XXXX) XXXXXXX) XXX XXXXXXXX (X -XXXXXXX). XX) WX XXXX) N S.

J. A. JOHNSON, WRENCH, 1. 413 121 application FILED MAR, 23, 92 Patented Apr. 1, 1922. s 9 A.L. 2 she ETS-SHEET 2. exxx: XXXXXXX) XX XXXXX. (XXXX) XXXXXXX) XXX XXXXXXXX (X -XXXXXXX). XX) WX XXXX) N S.

Circuit Court, D. Connecticut. January 16, 1882.

COES V. THE COLLINS CO. Circuit Court, D. Connecticut. January 16, 1882. 1. LETTERS PATENT WRENCHES INFRINGEMENT. The first claim of reissued letters patent No. 3, 483, granted to Loring Coes, June 1,

COES V. THE COLLINS CO. Circuit Court, D. Connecticut. January 16, 1882. 1. LETTERS PATENT WRENCHES INFRINGEMENT. The first claim of reissued letters patent No. 3, 483, granted to Loring Coes, June 1,

SESSEA is. & NES51&are EAS. S. SY se E - SE: t EA S. s 433,042. S s S. SA8sšSissé - Patented 0ct, 24, S. s S. 48.

433,042. J. B. SED BERRY, GRN DING MLL APPLICATION FILED MAY 4, 1920, Patented 0ct, 24, 1922. 4 SHEETS-SHEET S. Q R. AE -- i. - N SE: t EA S. s is & NES51&are EAS S. - G w -- 6) G GEE S. SY se E - & Ši

433,042. J. B. SED BERRY, GRN DING MLL APPLICATION FILED MAY 4, 1920, Patented 0ct, 24, 1922. 4 SHEETS-SHEET S. Q R. AE -- i. - N SE: t EA S. s is & NES51&are EAS S. - G w -- 6) G GEE S. SY se E - & Ši

(12) Patent Application Publication (10) Pub. No.: US 2009/ A1

(19) United States US 20090090231A1 (12) Patent Application Publication (10) Pub. No.: US 2009/0090231 A1 Kondo (43) Pub. Date: ADr. 9, 9 2009 (54) BAND SAW MACHINE Publication Classification O O (51)

(19) United States US 20090090231A1 (12) Patent Application Publication (10) Pub. No.: US 2009/0090231 A1 Kondo (43) Pub. Date: ADr. 9, 9 2009 (54) BAND SAW MACHINE Publication Classification O O (51)

SERVICING MANUAL 419S/423S

SERVICING MANUAL 415 419S/423S TROUBLESHOOTING PROBLEM CAUSE REMEDY REFERENCE 1. SKIPPING 1. NEEDLE IS NOT INSERTED INSERT THE NEEDLE PROPERLY. STITCHES PROPERLY. 2. NEEDLE IS BENT OR WORN. CHANGE THE

SERVICING MANUAL 415 419S/423S TROUBLESHOOTING PROBLEM CAUSE REMEDY REFERENCE 1. SKIPPING 1. NEEDLE IS NOT INSERTED INSERT THE NEEDLE PROPERLY. STITCHES PROPERLY. 2. NEEDLE IS BENT OR WORN. CHANGE THE

A, L, LOOMS,???, APPLICAT 10N Fi ED 3 ULY

A, L, LOOMS,???, APPLICAT 10N Fi ED 3 ULY 22 91 5.,-----------------------------------------------------------=----------=--------------?-?-----------??------------------------------------------------------------??

A, L, LOOMS,???, APPLICAT 10N Fi ED 3 ULY 22 91 5.,-----------------------------------------------------------=----------=--------------?-?-----------??------------------------------------------------------------??

No. 633,672. Patented Sept. 26, H. L. & F. X. WAGNER. TYPE WRITING MACHINE. (Application filed July 7, 1897.) (No Model.) 8 Sheets-Sheet..

No. 633,672. Patented Sept. 26, 1899. H. L. & F. X. WAGNER. TYPE WRITING MACHINE. (Application filed July 7, 1897.) (No Model.) 8 Sheets-Sheet.. s (GD Y. (d (e. (e)s e (e. (e. (2) (S) (3) G (e. (e) s Š

No. 633,672. Patented Sept. 26, 1899. H. L. & F. X. WAGNER. TYPE WRITING MACHINE. (Application filed July 7, 1897.) (No Model.) 8 Sheets-Sheet.. s (GD Y. (d (e. (e)s e (e. (e. (2) (S) (3) G (e. (e) s Š

United States Patent (19) Sherlock et al.

United States Patent (19) Sherlock et al. (54) (75) (73) (21) 22 (51) (52) (58) (56) SKN FOLD CAL PER Inventors: Hugh P. Sherlock, Palo Alto; Allan M. Golderg, Laguna Niguel; Werner W. Ciupke, Burlingame;

United States Patent (19) Sherlock et al. (54) (75) (73) (21) 22 (51) (52) (58) (56) SKN FOLD CAL PER Inventors: Hugh P. Sherlock, Palo Alto; Allan M. Golderg, Laguna Niguel; Werner W. Ciupke, Burlingame;

Smith et al. (45) Date of Patent: Nov. 26, (73 Assignee: Molex Incorporated, Lisle, Ill. 57) ABSTRACT

United States Patent (19) 11 US005577318A Patent Number: Smith et al. (45) Date of Patent: Nov. 26, 1996 54 ELECTRICAL TERMINAL APPLICATOR FOREIGN PATENT DOCUMENTS WEMPROVED TRACK ADJUSTMENT 2643514 8/1990

United States Patent (19) 11 US005577318A Patent Number: Smith et al. (45) Date of Patent: Nov. 26, 1996 54 ELECTRICAL TERMINAL APPLICATOR FOREIGN PATENT DOCUMENTS WEMPROVED TRACK ADJUSTMENT 2643514 8/1990

Fig. 3. BY r: 42.e4.14ce. Oct. 13, 1970 H. HEITMULLER E.T A. 3,533,197 PLIERS, PARTICULARLY NIPPERS INVENTOR.

Oct. 13, 1970 H. HEITMULLER E.T A. 3,533,197 METHOD OF SHARPENING THE CUTTING EDGES OF SIDE CUTTING Filed March 27, 1967 PLIERS, PARTICULARLY NIPPERS 4. Sheets-Sheet Fig. 3 4 BY r: INVENTOR. 42.e4.14ce

Oct. 13, 1970 H. HEITMULLER E.T A. 3,533,197 METHOD OF SHARPENING THE CUTTING EDGES OF SIDE CUTTING Filed March 27, 1967 PLIERS, PARTICULARLY NIPPERS 4. Sheets-Sheet Fig. 3 4 BY r: INVENTOR. 42.e4.14ce

SERVICE MANUAL PARTS LIST MODEL: NH40

SERVICE MANUAL & PARTS LIST MODEL: NH40 CONTENTS What to do when... 1-3 SERVICE ACCESS Face Cover... 4 Bed Cover... 5 Free-arm Cover... 6 Front Cover... 7 Rear Cover... 8 MECHANICAL ADJUSTMENT Presser

SERVICE MANUAL & PARTS LIST MODEL: NH40 CONTENTS What to do when... 1-3 SERVICE ACCESS Face Cover... 4 Bed Cover... 5 Free-arm Cover... 6 Front Cover... 7 Rear Cover... 8 MECHANICAL ADJUSTMENT Presser

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150.074942A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0074942 A1 HAAB et al. (43) Pub. Date: Mar. 19, 2015 (54) ADJUSTABLE MOUNTING DEVICE FORA SLIDINGELEMENT

(19) United States US 20150.074942A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0074942 A1 HAAB et al. (43) Pub. Date: Mar. 19, 2015 (54) ADJUSTABLE MOUNTING DEVICE FORA SLIDINGELEMENT

Patented my 30, was. No. 625,905. (NO Model.) L. G. SOUDEB. > MOVING STAlRWAY 0R ELEVATOR. (Appumién?led Dec. 10, 1898.) " 3 Shoots-Sheet.

No. 625,905. (NO Model.) L. G. SOUDEB. > MOVING STAlRWAY 0R ELEVATOR. (Appumién?led Dec. 10, 1898.) Patented my 30, was. " 3 Shoots-Sheet. No. 625,905. Patented May 30, I899. L. G. SOUDER. MOVING STAIRWAY

No. 625,905. (NO Model.) L. G. SOUDEB. > MOVING STAlRWAY 0R ELEVATOR. (Appumién?led Dec. 10, 1898.) Patented my 30, was. " 3 Shoots-Sheet. No. 625,905. Patented May 30, I899. L. G. SOUDER. MOVING STAIRWAY

Operating Instructions

Operating Instructions Holding the material against the angle gauge slide it into the forming head. Be sure that the material remains against the gauge until work is finished. NOTE: This machine will handle

Operating Instructions Holding the material against the angle gauge slide it into the forming head. Be sure that the material remains against the gauge until work is finished. NOTE: This machine will handle

S T E P 1. Tools Needed. Curved Needle Nose Pliers. L Shaped Tool (Supplied w/ kit) Flathead Eyeglasses Screwdriver

Curved Needle Nose Pliers Flathead Eyeglasses Screwdriver L Shaped Tool (Supplied w/ kit) Tools Needed 2 Make sure weapon is pointed in a safe direction, unloaded, and on safe. 3 Remove lower receiver

Curved Needle Nose Pliers Flathead Eyeglasses Screwdriver L Shaped Tool (Supplied w/ kit) Tools Needed 2 Make sure weapon is pointed in a safe direction, unloaded, and on safe. 3 Remove lower receiver

July 23, O. FSCHER 2,209,156. PHOTOGRAPHC CAMERA Filed July 8, Sy AN SS 2 Y 2 N 2>24. E-4. N Liga 2 2 S.12YZ, Z2 2Z) Š-32.

July 23, 19.. FSCHER 2,9,16 PHTGRAPHC CAMERA Filed July 8, 1939 2 Y 2 Sy AN SS 3% T2N N3 N 2>24. E-4 3% yes/zz N Liga 2 2 S.12YZ, Z2 22 2Z) Š-32 A. away SSSSSS Patented July 23, 19 2,9,16 s UNITED STATES

July 23, 19.. FSCHER 2,9,16 PHTGRAPHC CAMERA Filed July 8, 1939 2 Y 2 Sy AN SS 3% T2N N3 N 2>24. E-4 3% yes/zz N Liga 2 2 S.12YZ, Z2 22 2Z) Š-32 A. away SSSSSS Patented July 23, 19 2,9,16 s UNITED STATES

Electric Skein Winder

Electric Skein Winder Assembly and Use Package Contents 1 - Triangular Body (w/ motor) 1 - Cross Arm 1 - Left Foot (w/ yarn guide) 1 - Right Foot 1 - Adjustable Finger (w/ yarn clip) 3 - Adjustable Fingers

Electric Skein Winder Assembly and Use Package Contents 1 - Triangular Body (w/ motor) 1 - Cross Arm 1 - Left Foot (w/ yarn guide) 1 - Right Foot 1 - Adjustable Finger (w/ yarn clip) 3 - Adjustable Fingers

Astro-Physics Inc. 400QMD Lubrication/Maintenance Guide

Astro-Physics Inc. 400QMD Lubrication/Maintenance Guide The following guidelines should be followed to lubricate the three main parts of the 400QMD mount. The QMD stands for Quartz Micro-Drive controller.

Astro-Physics Inc. 400QMD Lubrication/Maintenance Guide The following guidelines should be followed to lubricate the three main parts of the 400QMD mount. The QMD stands for Quartz Micro-Drive controller.

United States Patent (19) Womack

United States Patent (19) Womack (4) DISPENSER FOR A PLURALITY OF ROLLS OF SHEET MATERAL 76 Inventor: Rolla J. Womack, P.O. Box. 6, Dawson, Ill. 6220 848,90 21) Appl. No.: 22 Filed: Nov. 7, 1977 1) Int.

United States Patent (19) Womack (4) DISPENSER FOR A PLURALITY OF ROLLS OF SHEET MATERAL 76 Inventor: Rolla J. Womack, P.O. Box. 6, Dawson, Ill. 6220 848,90 21) Appl. No.: 22 Filed: Nov. 7, 1977 1) Int.

July 26, 1966 N. S. WATERMAN Filed July 29, 1963 2 Sheets-Sheet NNNN NaNYS3% SSSSSSSSSSSSN 33 A S4 22222222222222222222222 242S 4% as -a-mo as amo- aga 2 --------- ---------- 6 INVENTOR. Neil S. Waterman

July 26, 1966 N. S. WATERMAN Filed July 29, 1963 2 Sheets-Sheet NNNN NaNYS3% SSSSSSSSSSSSN 33 A S4 22222222222222222222222 242S 4% as -a-mo as amo- aga 2 --------- ---------- 6 INVENTOR. Neil S. Waterman

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION PREPARATION FOR OPERATION CAUTIONS ON USE OPERATION

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION ------------------------------------- 1 PREPARATION FOR OPERATION 1. Adjustment of needle bar stop position ---------------------------------------------------------

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION ------------------------------------- 1 PREPARATION FOR OPERATION 1. Adjustment of needle bar stop position ---------------------------------------------------------

April 1, 1969 W. JONAs ET AL 3,435,988. PAPER Cup DISPENSER. Filed March 20, 1968 Sheet / of 2 N S. INVENTORs WALTER JONAS. ADOLF PFUND. ATTORNEY.

April 1, 1969 W. JONAs ET AL. PAPER Cup DISPENSER Filed March 20, 1968 Sheet / of 2 N S. N ) INVENTORs WALTER JONAS. ADOLF PFUND. ATTORNEY. April 1, 1969 filed March 20, 1968 Sºzzzzzzzz!,, ~~~~ FIG 5.

April 1, 1969 W. JONAs ET AL. PAPER Cup DISPENSER Filed March 20, 1968 Sheet / of 2 N S. N ) INVENTORs WALTER JONAS. ADOLF PFUND. ATTORNEY. April 1, 1969 filed March 20, 1968 Sºzzzzzzzz!,, ~~~~ FIG 5.

TRAINING BULLETIN FORCIBLE ENTRY 1 March 15, 1997 FORCIBLE ENTRY TABLE OF CONTENTS. 1. Introduction. 2. Doors-Inward Opening. 3. Doors-Outward Opening

TRAINING BULLETIN 1 March 15, 1997 TABLE OF CONTENTS 1. Introduction 2. Doors-Inward Opening 3. Doors-Outward Opening 4. Through The Lock Method 5. Padlocks 6. American Lock Series 2000 7. Bars And Sliding

TRAINING BULLETIN 1 March 15, 1997 TABLE OF CONTENTS 1. Introduction 2. Doors-Inward Opening 3. Doors-Outward Opening 4. Through The Lock Method 5. Padlocks 6. American Lock Series 2000 7. Bars And Sliding

OPERATING INSTRUCTIONS 3421UX VETERANS BLVD, CARLSTADT, NJ 07072

OPERATING INSTRUCTIONS 3421UX5-1 400 VETERANS BLVD, CARLSTADT, NJ 07072 CONTENTS DESCRIPTION... 3 OPERATOR INFORMATION... 5-8 INSTALLATION...... 4 ADJUSTMENT... 8-17 LUBRICATION... 5 INDEX Description

OPERATING INSTRUCTIONS 3421UX5-1 400 VETERANS BLVD, CARLSTADT, NJ 07072 CONTENTS DESCRIPTION... 3 OPERATOR INFORMATION... 5-8 INSTALLATION...... 4 ADJUSTMENT... 8-17 LUBRICATION... 5 INDEX Description

T T. Cózz , S == No. 607,270. Patented July 2, (Application filed Sept. 24, 1896) 8 Sheets-Sheet.

No. 607,270. Patented July 2, 1898. E. PASTRE & F. AMBERT. TYPE WRITING MACHINE. (No Model.) (Application filed Sept. 24, 1896) 8 Sheets-Sheet. T T. Cózz. 44. 7, S == No. 607,270. (No Mode.) Patented July

No. 607,270. Patented July 2, 1898. E. PASTRE & F. AMBERT. TYPE WRITING MACHINE. (No Model.) (Application filed Sept. 24, 1896) 8 Sheets-Sheet. T T. Cózz. 44. 7, S == No. 607,270. (No Mode.) Patented July

IIH. United States Patent (19) Chen. (11) Patent Number: 5,318,090 (45. Date of Patent: Jun. 7, 1994

United States Patent (19) Chen 54) ROLLER ASSEMBLY FORVENETIAN BLIND 76 Inventor: Cheng-Hsiung Chen, No. 228, Sec. 2, Chung-Te Rd., Taichung City, Taiwan 21 Appl. No.: 60,278 22 Filed: May 11, 1993 51)

United States Patent (19) Chen 54) ROLLER ASSEMBLY FORVENETIAN BLIND 76 Inventor: Cheng-Hsiung Chen, No. 228, Sec. 2, Chung-Te Rd., Taichung City, Taiwan 21 Appl. No.: 60,278 22 Filed: May 11, 1993 51)

BY ALIEN TECHNOLOGIES CORP

BY ALIEN TECHNOLOGIES CORP Assembly Instructions TopLift Pros YOU MAY ALSO REVIEW OUR ASSEMBLY VIDEO, PLAY AND PAUSE AT YOUR CONVENIENCE. JUST VISIT US AT WWW.TOPLIFTPROS.COM AND GO TO Customer Support

BY ALIEN TECHNOLOGIES CORP Assembly Instructions TopLift Pros YOU MAY ALSO REVIEW OUR ASSEMBLY VIDEO, PLAY AND PAUSE AT YOUR CONVENIENCE. JUST VISIT US AT WWW.TOPLIFTPROS.COM AND GO TO Customer Support

No Model.) 4 sheets-sheet l. C. F. T. STEINWAY. PIANO FRAME. No. 314,742, Patented Mar. 31, WITNESSES; -Y e44. city as 44 ATTORNEYS

No Model.) 4 sheets-sheet l. C. F. T. STEINWAY. PIANO FRAME. No. 314,742, Patented Mar. 31, 1885. T - -- WITNESSES; -Y 376-4 e44 city as 44 ATTORNEYS (No Model.) 4. Sheets-Sheet 2. v. C. F. T. STEINWAY.

No Model.) 4 sheets-sheet l. C. F. T. STEINWAY. PIANO FRAME. No. 314,742, Patented Mar. 31, 1885. T - -- WITNESSES; -Y 376-4 e44 city as 44 ATTORNEYS (No Model.) 4. Sheets-Sheet 2. v. C. F. T. STEINWAY.

Appl. No.: 619,775 Filed: Nov. 29, 1990 Int. Cl... E21B 4/02 U.S. Cl /907. 1; 175/ /95, 97, 282,303,

United States Patent (19) Justman et al. (54) (75) (73) 21 22 (51) (52) (58) 56) BEARING STRUCTURE FOR DOWNHOLE MOTORS Inventors: Dan B. Justman, Houston; George A. Cross, Kingwood, both of Tex. Assignee:

United States Patent (19) Justman et al. (54) (75) (73) 21 22 (51) (52) (58) 56) BEARING STRUCTURE FOR DOWNHOLE MOTORS Inventors: Dan B. Justman, Houston; George A. Cross, Kingwood, both of Tex. Assignee:

United States Patent (19) Schreuders

United States Patent (19) Schreuders 54 DEVICE FOR CUTTING GAS CONCRETE (75) Inventor: Willem J. Schreuders, Staphorst, Netherlands 73) Assignee: Durox Gasbeton B.V., Netherlands (21) Appl. No.: 149,677

United States Patent (19) Schreuders 54 DEVICE FOR CUTTING GAS CONCRETE (75) Inventor: Willem J. Schreuders, Staphorst, Netherlands 73) Assignee: Durox Gasbeton B.V., Netherlands (21) Appl. No.: 149,677

No. 412, 414, 416 Operations Manual

No. 412, 414, 416 Operations Manual CARE: Occasional oiling of moving parts with machine oil will ease operation and extend the life of the brake. Occasionally check and tighten the lower beam bracket

No. 412, 414, 416 Operations Manual CARE: Occasional oiling of moving parts with machine oil will ease operation and extend the life of the brake. Occasionally check and tighten the lower beam bracket

March 8, 1966 F. F. STUBBS 3,238,939 WRIST SUPPORT. Zas ZZ INVENTOR aa/a 277, S7 eveas " R attoane Y

March 8, 1966 F. F. STUBBS 3,238,939 WRIST SUPPORT Filed Feb. 23, 1965 3 Sheets-Sheet l 2 Zas ZZ 17.1- INVENTOR. 3. 27 30 22 2 22aa/a 277, S7 eveas " R. 8-7. attoane Y March 8, 1966 F. F. SUBBS 3,238,939

March 8, 1966 F. F. STUBBS 3,238,939 WRIST SUPPORT Filed Feb. 23, 1965 3 Sheets-Sheet l 2 Zas ZZ 17.1- INVENTOR. 3. 27 30 22 2 22aa/a 277, S7 eveas " R. 8-7. attoane Y March 8, 1966 F. F. SUBBS 3,238,939

Double-lift Jacquard mechanism

United States Patent: 4,416,310 1/20/03 4:08 PM ( 102 of 131 ) United States Patent 4,416,310 Sage November 22, 1983 Double-lift Jacquard mechanism Abstract A double-lift Jacquard mechanism in which the

United States Patent: 4,416,310 1/20/03 4:08 PM ( 102 of 131 ) United States Patent 4,416,310 Sage November 22, 1983 Double-lift Jacquard mechanism Abstract A double-lift Jacquard mechanism in which the

United States Patent (19) Manfroni

United States Patent (19) Manfroni 54 scraper AND MIXER ELEMENT FOR ICE CREAM MAKING MACHINES 75) Inventor: Ezio Manfroni, Sasso Marconi, Italy 73 Assignee: Carpigiani Bruto Macchine Automatiche S.P.A.,

United States Patent (19) Manfroni 54 scraper AND MIXER ELEMENT FOR ICE CREAM MAKING MACHINES 75) Inventor: Ezio Manfroni, Sasso Marconi, Italy 73 Assignee: Carpigiani Bruto Macchine Automatiche S.P.A.,

RZ. United States Patent (19) 1,005,563 1/19i Petit. 147/7. Whyte. 11) 4,279, Jul. 21, Filed: Aug. 27, 1979

United States Patent (19) Whyte (54) BARREL HOOP DRIVERS 76 Inventor: Robert N. Whyte, 28 Rubislaw-Den South, Aberdeen, Scotland 21 Appl. No.: 69,621 22 Filed: Aug. 27, 1979 51 Int. Cl... B27H5/10 52 U.S.

United States Patent (19) Whyte (54) BARREL HOOP DRIVERS 76 Inventor: Robert N. Whyte, 28 Rubislaw-Den South, Aberdeen, Scotland 21 Appl. No.: 69,621 22 Filed: Aug. 27, 1979 51 Int. Cl... B27H5/10 52 U.S.

22a, a JW ttorneys RAYMONDJ. TESTER. March 15, 1960 R. J. TESTER 2,928,439 AND ALL CUTS PASSING THROUGH A COMMON POINT

March 15, 1960 R. J. TESTER 2,928,439 BAND SAW MACHINE MAKING CUTSAT WARIOUS ANGLES AND ALL CUTS PASSING THROUGH A COMMON POINT Filed July 21, 1958 4. Sheets-Sheet, I RAYMONDJ. TESTER BY 22a, a 477-24.

March 15, 1960 R. J. TESTER 2,928,439 BAND SAW MACHINE MAKING CUTSAT WARIOUS ANGLES AND ALL CUTS PASSING THROUGH A COMMON POINT Filed July 21, 1958 4. Sheets-Sheet, I RAYMONDJ. TESTER BY 22a, a 477-24.

Daily Maintenance. 2. Insert bobbin cases in to rotary hooks. Make sure bobbin thread is not over 2 inches long. Close bobbin case covers.

Rotary hook 1. Open bobbin case covers and remove bobbin cases. Use brush to remove lint build up in and around rotary hooks. Compressed air may also be used. Daily Maintenance Cle aning Oiling Rotary

Rotary hook 1. Open bobbin case covers and remove bobbin cases. Use brush to remove lint build up in and around rotary hooks. Compressed air may also be used. Daily Maintenance Cle aning Oiling Rotary

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 20120312936A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0312936A1 HUANG (43) Pub. Date: Dec. 13, 2012 (54) HOLDING DEVICE OF TABLET ELECTRONIC DEVICE (52) U.S. Cl....

US 20120312936A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0312936A1 HUANG (43) Pub. Date: Dec. 13, 2012 (54) HOLDING DEVICE OF TABLET ELECTRONIC DEVICE (52) U.S. Cl....

United States Patent (19) [11] 3,858,302 Abarotin (45) Jan. 7, 1975

![United States Patent (19) [11] 3,858,302 Abarotin (45) Jan. 7, 1975 United States Patent (19) [11] 3,858,302 Abarotin (45) Jan. 7, 1975](/thumbs/90/103042900.jpg) United States Patent (19) [11] 3,858,302 Abarotin (45) Jan. 7, 1975 54 METHOD OF PREPARIG THE EDS OF 3,706,241-12/1972 Balmer et al... 819.51 CABLES FOR SPLICIG 3,768, 143 10/1973 Holmes... 8119.51 3,774,478

United States Patent (19) [11] 3,858,302 Abarotin (45) Jan. 7, 1975 54 METHOD OF PREPARIG THE EDS OF 3,706,241-12/1972 Balmer et al... 819.51 CABLES FOR SPLICIG 3,768, 143 10/1973 Holmes... 8119.51 3,774,478

United States Patent (19)

United States Patent (19) US00564117OA 11 Patent Number: 5,641,170 Helm 45 Date of Patent: Jun. 24, 1997 54 76) 21 22 51 52 58 PORTABLE TOOL CARRER AND DISPLAY BOX Inventor: Paul E. Helm, 2028 Ridge Rd.,

United States Patent (19) US00564117OA 11 Patent Number: 5,641,170 Helm 45 Date of Patent: Jun. 24, 1997 54 76) 21 22 51 52 58 PORTABLE TOOL CARRER AND DISPLAY BOX Inventor: Paul E. Helm, 2028 Ridge Rd.,

United States Patent (19) Van Halen

United States Patent (19) Van Halen 11) () Patent Number: Date of Patent: Apr. 14, 1987 54 MUSICAL INSTRUMENT SUPPORT 76 Inventor: Edward L. Van Halen, 1900 Ave. of Stars #1780, Los Angeles, Calif. 90067

United States Patent (19) Van Halen 11) () Patent Number: Date of Patent: Apr. 14, 1987 54 MUSICAL INSTRUMENT SUPPORT 76 Inventor: Edward L. Van Halen, 1900 Ave. of Stars #1780, Los Angeles, Calif. 90067

MANUAL PLASTIC STRAPPING TOOL MODEL P404

OPERATION MANUAL / SPARE PARTS LIST MANUAL PLASTIC STRAPPING TOOL MODEL P404 43.0404.02 43040402.en/MAS/ 12.05 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 TECHNICAL DATA 3 3 OPERATION ELEMENTS 4 4 ADJUSTMENT

OPERATION MANUAL / SPARE PARTS LIST MANUAL PLASTIC STRAPPING TOOL MODEL P404 43.0404.02 43040402.en/MAS/ 12.05 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 TECHNICAL DATA 3 3 OPERATION ELEMENTS 4 4 ADJUSTMENT

Student, Department of Mechanical Engineering, Knowledge Institute of Technology, Salem, Tamilnadu (1,3)

International Journal of Scientific & Engineering Research, Volume 7, Issue 5, May-2016 11 Combined Drilling and Tapping Machine by using Cone Mechanism N.VENKATESH 1, G.THULASIMANI 2, S.NAVEENKUMAR 3,

International Journal of Scientific & Engineering Research, Volume 7, Issue 5, May-2016 11 Combined Drilling and Tapping Machine by using Cone Mechanism N.VENKATESH 1, G.THULASIMANI 2, S.NAVEENKUMAR 3,

REPAIR INSTRUCTIONS. Cat. No Cat. No MILWAUKEE ELECTRIC TOOL CORPORATION. SDS Max Demolition Hammer. SDS Max Rotary Hammer

Cat. No. 9-0 SDS Max Demolition Hammer Cat. No. -0 SDS Max Rotary Hammer MILWAUKEE ELECTRIC TOOL CORPORATION W. LISBON ROAD BROOKFIELD, WISCONSIN 00-0 8-9-0 d 000 8-9-0 d Special Tools Require Forcing

Cat. No. 9-0 SDS Max Demolition Hammer Cat. No. -0 SDS Max Rotary Hammer MILWAUKEE ELECTRIC TOOL CORPORATION W. LISBON ROAD BROOKFIELD, WISCONSIN 00-0 8-9-0 d 000 8-9-0 d Special Tools Require Forcing

(12) United States Patent

(12) United States Patent Mack USOO686.0488B2 (10) Patent No.: (45) Date of Patent: Mar. 1, 2005 (54) DRILL CHUCK WITH FRONT-END SHIELD (75) Inventor: Hans-Dieter Mack, Sontheim (DE) (73) Assignee: Rohm

(12) United States Patent Mack USOO686.0488B2 (10) Patent No.: (45) Date of Patent: Mar. 1, 2005 (54) DRILL CHUCK WITH FRONT-END SHIELD (75) Inventor: Hans-Dieter Mack, Sontheim (DE) (73) Assignee: Rohm