2 [In equity. Final hearing on pleadings and proofs. Suit brought [by Alpheus C. Gallahue

|

|

|

- Blanche May

- 5 years ago

- Views:

Transcription

1 YesWeScan: The FEDERAL CASES GALLAHUE ET AL. V. BUTTERFIELD. Case No. 5,198. [10 Blatchf. 232; 6 Fish. Pat Cas. 203; 2 O. G. 645; Merw. Pat Inv. 340.] 1 Circuit Court, S. D. New York. Dec. 6, PATENTS VALIDITY INFRINGEMENT REISSUE TO COVER SEPARATE DEVICES COMBINATION NEW RESULTS ABANDONED EXPERIMENT. 1. The claims of the reissued patent granted to Alpheus C. Gallahue, July 6th, 1869, (the original patent having been granted to him August 16th, 1853, and extended,) and of the reissued patent granted to said Gallahue, June 22d, 1869, (the original patent having been granted to him March 29th, 1859,) and of the patent granted to said Gallahue, August 26th, 1862, all for improvements in machines for pegging shoes, considered. 2. A patentee, in his original patent, described a spring and a weight, acting conjointly to drive down an awl-carrier and a peg-driver. In a reissue of the patent, he claimed the use of the spring alone, for that purpose, without the weight. The defendant used for the purpose, a powerful spring, equivalent to the spring and weight: Held, that the claim in the reissue was valid, and that the defendant infringed it. 3. A patentee, whose devices are new, is at liberty to claim each, by way of reissue, although he may have represented and claimed them originally as acting conjointly. [Cited in Calkins v. Bertrand, Case No. 2,317; Gould v. Ballard, Id. 5,635; Holmes Burglar-Alarm Tel. Co. v. Domestic, etc., Tel. Co., 42 Fed. 224.] 4. It is not true of a machine, as such, that, because every one of its members performs in it the identical office which it would perform howsoever used, their conjoint action in the new combination may not produce a result useful and never before attained. 5. Where one or more of the parts are new, and the combination is, for that reason, made to produce a new result, in the greater rapidity and economy with which the work can be performed, there is something more than mere aggregation. 6. Where the patentee drove his awl-carrier by a spring made to operate automatically, and the use of such spring, for such purpose, was new, and could not be usefully employed without the use of a gauge for the edge of the sole to rest against: Held, that the combination of a gauge with an awl-carrier driven by a spring was a new combination, and not a mere aggregation, although the gauge and the awl-carrier were old, and operated, in relation to each other, in no new manner, in the new combination. 7. Where a machine, not brought into effective operation, was cast aside and taken apart, without any intention to reconstruct it, portions of it being appropriated to other uses, and the remaining parts being wholly useless for any purpose within the purview of a subsequent patent: Held, that, as an answer to such patent, such machine must be regarded as an abandoned experiment. 1

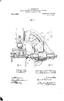

2 GALLAHUE et al. v. BUTTERFIELD. 2 [In equity. Final hearing on pleadings and proofs. Suit brought [by Alpheus C. Gallahue and Eli Bennet against William Butterfield] upon patent [No. 9,947] for improved machine for pegging boots and shoes, granted A. C. Gallahue, August 16, 1853; extended seven years, and afterward reissued under date of July 6, 1869 [No. 3,533]; also, letters patent [No. 23,361] granted same, under same title, March 29, 1859, and reissued June 22, 1869 [No. 3,517]; also, letters patent [No. 36,292] granted same, under same title, August 26, [The accompanying engravings represent the Gallahue machine, as shown in the reissue of July 6,

3 3 YesWeScan: The FEDERAL CASES

4 GALLAHUE et al. v. BUTTERFIELD. [The specification states the nature of the Invention to consist in [ So constructing a machine that the punching of holes, cutting pegs, and driving them by percussion (not forcing) into the soles of boots or shoes, is performed at one operation; and that, instead of moving the machine over and around the work, which is attended with great complexity of machinery and expense, I am enabled to move my work under the operative portions of the machine, and, by simplifying the mechanism, greatly reduce the cost, and render practical the operation, as applied to all sizes and shapes of the sole, without any change being necessary, except that of substituting one of the ordinary lasts for another. [In the engraving, II represents the last of the ordinary form. It is provided with a staple o', for securing it on the block m', m', and at one end of this block there is a slight hollow to receive the toe, while the other end is flat to receive the heel of the last. S', S' represent a metallic plate, having uprights, 4s, 4s, between which the block m', m', is placed, it being secured by screws to S', S'. This plate forms a turn-table for the last, the pivot thereof being a shaft under the center of the heel, by which the ends of the shaft are reversed. The last is secured to the block and turn-table S' by a lever, n', passing entirely through m', m', and through slots in 4s, 4s, and having a hook for entering the staple O' in the last. By the driving of a wedge, q', in the slot 4s, the lever is depressed, and, drawing on the hook and staple, secures the last firmly on m', m'. x' x' is the base of the machine; w', a sliding table thereon, moving longitudinally by tongues and grooves, through the agency of racks and a pinion; v is a second table, vibrating back and forth on w' u' is a rail supporting the turn-table S' and toe of the last. At each end of the rail is a square notch or stop, a', in which the spring-handle r of the turn-table drops on the alternate change in the position of the last in pegging each side. The straight portion of the rail on the edge of o supports the last-holder when the heel is being pegged. w, w are uprights secured to the base x', and are braced with a cross tie, J. u, u are sides of a sliding-gate, working in upright guides on w. r is a cross-head connecting u, u. P is the main or driving shaft, which, through a screw and cog-wheel operates the shaft 13. On the lower portion of shaft 13, slides a pinion, which has motion given it by a sliding key and slot in the shaft and pinion. Two racks, 6 and 7, one above the other, are extended horizontally, so that this pinion engages in one or the other, according as it is raised or lowered by a lever-operated in connection with the helical spring k'. The raising of the pinion changes its gear in giving the table w' motion toward the right. After finishing the shoe, the table is returned by hand. The slight transverse motion of the table o, required on account of the inequality of width of the soles, is permitted by the extension and contraction of helical springs placed under v', one end being secured to the side of v', the other end to the side of w'. By means of these springs, the edge of the sole is always kept up to the gauge a, back of the awl d, under the peg-driver. The gauge a is made 4

5 YesWeScan: The FEDERAL CASES adjustable, so that by changing it, any desired number of rows can be pegged around the shoe, one after another. [By the pinion D, on the horizontal shaft B, which carries a bevel-wheel, B, meshing in a second bevel-wheel F, on the upright shaft c, motion is given to the turn-table S', placed on the upper end of the shaft, when required in turning the last in pegging the heel. A lever, c' c', pivoted at 4f, and a pitman, y', attached to r, and a weight, bb, as a counterpoise to adjust the weight of the sliding-frame on the roller f, pressing on the sole, serves as a means of giving greater or less pressure to this frame. The lever 16 is held down by a catch, 3s, until it is relieved by the short projecting arm, 3t, striking against it when the spring k' lifts the lever 16 and pinion from rack 7 to rack 6. H is a flat spring secured to the base x', the upper end thereof resting upon the shoulder of the catch B. The pinion being now engaged with the rack, which slides by means of a slot therein on a screw z', projecting from the table w', carries with it the rack 5, and thus gives motion to the turn-table S'. The same arm, 3t, now is moved against the catch L, and throws it from under the spring H, which depresses lever 16, and throws the pinion out of rack 6 into rack 7. N is a triphammer secured to the front of the base x', and acts on the spring 50 and lever 51, placed under the spring-handle r', throwing said spring-handle out of the stop a', when the lever 16 is lifted by the helical spring k', and thus permits the turn-table to change the position of the last, while the pegs are being Inserted in the heel after one side is finished; then the pinion 9, in gear with rack 7, continues moving the table w' and the last still further to the right, and finishes the shoe. [The pegging portion is represented by h, a rod in Fig. 3; the lower end carries the awl d, and the upper end the head z. f' is a helical spring attached to the head, giving the awl-rod a quick stroke when released from the cam 53, Fig. 3. The arm having been lifted by an arm, 54, projecting from the square rod 52, is also connected with z. This cam also holds up the rod and awl while the I peg is being inserted. The spring f' has its lower end secured by a staple to the ways 60, in which there is a series of holes for adjusting the staple up or down, and thus to I regulate the tension of the spring so as to I strike a heavier or lighter blow, as may be required. X is a square hammer-head, sliding, independent 5

6 GALLAHUE et al. v. BUTTERFIELD. of the peg-driver, on the awl-rod h, said rod moving in stationary ways'60. Its use is to drive the pegs into the sole, and it is lifted by the end of cam 2, acting on a projecting arm 1, being held up by this cam (a portion seen in dotted lines,) while the awl is in operation, g' is a helical spring, giving a quick descending motion to the hammer, i, Fig. 1, is the rod of the peg-driver, lifted by a stirrup n (connected at 17), and by the cam e, on the main-shaft P. It slides on the face of the peg-cutter R by means of a slot, 18, and screw. The lower part of is rounded and reduced in size, so as to enter freely the tube below. The peg-wood passes through a slot in R, and stops against a spring gauge-plate, 10. At the mouth of this slot a knife is drawn upward, and splits the peg with the grain of the wood by the stirrup m, connected at 22, raising R, and forcing upward the wood against a stop pressing into a slot, in R, arrests it, and the peg is forced into the tube. This stop is adjustable, by a slot, to suit different lengths of peg-wood. T, the base-block, upon which all the sliding portions are secured, is swung to the frame-work by a screw, at its upper end, so as to admit of a slight change of position, to bring the peg over the previously punched hole in the sole, by means of the lever A, acted on by the side-cam o in its revolution. At g is the trough carrying the peg-wood, connected with this base. A finger forces up the peg-wood in g by the weight e, and cord passing over the stub on the side of T. L is a bent arm, on which the stirrups m and n are pivoted. [The operations of the machine, and the advantages secured by it, are thus described in the patent, viz.: [ The last being turned toward the wheel and handle on shaft P, the toe thereof toward the right hand, the edge of the sole bearing against the gauge a, and the drop-bar r', in a', under the toe, the peg-wood supplied in strips in the holder g, turn the shaft P toward the right, or in direction of dart. [ The cam 53 raises the hammer z, and rod 52, by a projecting arm, 54, thereon, and the awl-rod h, sliding in ways 60, and awl d, on the arm, 54, being released from the cam, the spring f quickens the descent of the awl, and drives it into the sole of the shoe. Then the cam e, through the stirrup n, lifts the peg-driver I sufficient to let the pegwood under it against the gauge 10, and the cam o, Fig. 3, the peg-cutter, and the cam 2 lifts the arm 1 of the sliding hammer Y, keeping it until the awl is raised out of the way by the cam 53 again coming in play, and both hammers are kept up until the upper end of the lever A being moved to the right, in the revolution of the wheel carrying the cam o (see Fig. 5, where this change of position is shown), while the lower end of A., entering a hole in the lower end of the base-block T, carrying the peg-tube and driver, gives it and them a slight side movement, independent of the awl and awl-rod, for the purpose of bringing the charged tube and driver over the previously punched hole in the sole. [ By the turning of cam 2, the arm 1 is released therefrom, and permits the head Y sliding on the awl-rod h, moving in fixed ways of the frame 60, to give a quick descending 6

7 YesWeScan: The FEDERAL CASES stroke on the head of the peg-driver, and thus insure the perfect insertion of each peg successively into the sole of the shoe. [ It is obvious that, instead of using the hammer to operate the peg-driver, and attaching the spring g' to that, the spring may be applied direct to the peg-driver, the same as is done with the awl-carrier, either plan being used at will. [ By this method of constructing a machine, many advantages are gained over the machines heretofore made. [ In all machines of this class, as previously constructed, the shoe or boot, when being pegged, was simply moved forward in a straight line, and, instead of gauging the row of pegs, by having the edge of the sole bearing against a gauge, as I do, they had to use patterns, corresponding in size and form to the boot or shoe being pegged, to gauge and form the rows, and at every change in the size or form of the boot or shoe the patterns had to be changed also. [ By my plan the sole itself becomes the pattern, and thus my machine, without any change or alteration, will peg a boot or shoe of any size or form, and by simply adjusting the gauge so as to throw the last further in or out, successive rows may be formed in the same manner. [ In the previously made machines, where the shoe simply moved to and fro, they could only peg along the sides, leaving a space around both heel and toe unpegged, and which had afterward to be finished by hand. [ By my plan of pivoting the last-holder, so that it can be turned around, I am enabled to continue the pegging entirely around the heel, starting at the toe on one side, and continuing around to the toe on the opposite side, thus completing at one operation the entire pegging, with the exception of a small space at the toe, where it is usual to insert nails. [ By using a spring, and attaching it directly to the awl-carrier, or to the weight attached rigidly thereto (if a weight be used), I drive the awl by a quick percussive movement, and then, by using a cam to withdraw the awl, I make sure of overcoming any tendency of the awl to stick in the sole. [ I rely on the spring for driving the awl, and it is obvious that the spring may be used for this purpose, with or without a weight, as may be desired; and by regulating 7

8 GALLAHUE et al. v. BUTTERFIELD. or altering the tension of the spring, the force of the blow can be adjusted to adapt the machine to the making of boots and shoes of any style, with soles light or heavy, thick or thin. [ I am aware that machines have heretofore been made in which a cam was used to force the awl and the peg into the sole, and a spring used to withdraw the awl, and therefore I do not claim broadly the use of a spring or cam in a pegging-machine. [The other two patents are subsequent modifications of this machine by the same inventor. [The decision of the court relates to some of the details of the machine, the nature of which are sufficiently indicated by the language of the court to render that portion of the decision intelligible without further explanation or description.] 3 C. M. Keller, for complainants. G. L. Roberts, for defendant. WOODRUFF, Circuit Judge. The bill of complaint herein is filed to restrain the alleged infringement of certain letters patent for machines for pegging shoes. A patent was granted to the complainant Gallahue, on the 16th of August, 1853, which was extended for seven years, on the 18th of February, 1867, and was afterwards surrendered and reissued under date of July 6th, Another patent was granted to the said complainant on the 29th of March, 1859, for another improvement, which was afterwards surrendered and reissued under date of June 22d, A third patent was granted to the said complainant on the 26th of August, 1862, for another improvement or improved machine. The other complainant claims as assignee of three-quarters of the right title, and interest of the patentee in or to these letters patent The bill alleges an infringement by the defendant of these several patents, and prays an injunction and an account of profits, &c. The answer does not deny the granting of the letters patent, or the extension and reissues alleged in the bill, but denies that Gallahue was the first inventor of the alleged inventions, denies that they were either new or useful, denies that they were granted according to law, alleges that the inventions were never reduced to practice, denies that the complainants have any exclusive rights under the patents, and denies that the defendant has infringed, alleging that the machines which he has been, and is now, selling are constructed under various other patents, which are specified, and which were granted at various dates, from January 17th, 1854, to October 11th, The answer also alleges, that the inventions claimed by the complainants were described, before the date of Gallahue's invention, in a very great number of letters patent mentioned in the answer, and were known to a great number of persons, also named therein; and, finally, the answer alleges abandonment of these inventions, by the patentee, to the public. The time which I have devoted to the examination and consideration of the voluminous testimony and documents put in evidence, and to the elaborate arguments of the 8

9 YesWeScan: The FEDERAL CASES counsel in an anxious endeavor to reach a just conclusion, and the numerous cases which are now before me awaiting examination and decision, both forbid that I should detain the parties longer in this court, for the purpose of doing more than state the conclusions to which I am brought; and the statement of those conclusions in brief must not suggest any failure to consider the points urged upon my attention, though not here separately discussed. (1.) First, I do not consider the objections urged to the validity of the reissues set up in the bill of complaint, tenable. On the contrary, the improvements described in the reissues were included in, and shown by, the original record; and I find also that the invention was complete, and was reduced to practical use and adaptation to the pegging of boots and shoes. (2.) Except so far as hereafter indicated, I find that the patentee, Gallahue, was not anticipated, in his invention, in any particular material to the decision which is below stated, and that the proof establishes that he was the first inventor of the devices secured by his patents, so far as such patents are found by me to be infringed by the defendant. (3.) I find it unnecessary to enter into a detailed examination of the machine made by Amos Whittemore, of which parts were produced in evidence, to ascertain whether, or to what extent, it included a device or devices like those invented by Gallahue, because the proofs show, in my judgment, that nothing in its history is any impediment to the force, effect, and validity of the patent of the latter. It was an abandoned experiment, within the rule on that subject, not brought into effective operation, cast aside and taken apart, and, without any intention to reconstruct it, portions of its machinery were appropriated to other uses, and the remaining parts were wholly useless, as a machine, for any purpose within the purview of the Invention of Gallahue. (4.) The foregoing conclusions lead to the consideration of the specific claims in the complainants' patents, and to the question of infringement 1st. The first claim in the reissue of July 6th, 1869, No. 3,533, is as follows: The use, in a pegging machine, of a gauge arranged in relation to the part that supports the boot or shoe, to form a bearing for the edge of the sole, and thus insure the insertion of the pegs at a uniform distance from the edge of the sole, without the use of patterns, substantially as described. If this claim should be construed to include any and every gauge which may be used, in 9

10 GALLAHUE et al. v. BUTTERFIELD. a pegging machine, as a guide to which the edge of the shoe may be applied, to regulate the distance, from such edge, at which the pegs shall be inserted,' then it is clear it could not be sustained. A gauge for that purpose had before been used, in the hand machine patented to John C. Briggs, October 0th, 1845, and a gauge performing a like office is also found in the machine made by Leander Lackey, which was invented earlier than that of Gallahue. Indeed, the counsel for the complainants, in substance, concedes, that, if such be the construction of the claim, it must be deemed invalid, for the reason stated. But, it is insisted, that, when read in connection with the whole specification, this claim may and should be construed as meaning the use of an adjustable gauge, in connection with the automatic movable support of the boot or shoe, while subjected to the operation of the automatic movement of the awl and driver described in the specification. The fact, that, in the Lackey machine, the gauge operated on the edge of the shoe, to guide it, while it was held to receive the awl and driver, acting automatically, to insert the peg, necessarily reduces even this construction of the claim to some extent, and requires that it be held to apply to those cases in which the specific kind of gauge described by Gallahue in this patent is used, or in which substantially the same movable support is given to the boot or shoe in the process, or, at least, in which substantially the same pegging machinery is used, for the insertion of the peg. The specific gauge used by the defendant has more resemblance to the Lackey gauge than to Gallahue's, and the support of the shoe employed by the defendant is a different mechanical structure from the movable table described in this first patent of Gallahue; and, though it may bring the machine within the range of Gallahue's exclusive right under his subsequent patent, it cannot be deemed an infringement of the claim under consideration, if such movable table be included in that claim. There remains, therefore, only the suggestion, that this claim embraces an adjustable gauge when used in connection with a movable support to the boot or shoe, and in connection with the pegging apparatus, that is, an awl-carrier and driver operated by a cam and spring or springs. In this aspect of the claim, it may properly be considered in connection with the other claims which more specifically relate thereto. 2nd. The next claim of this reissue, alleged to be infringed, is the third: The combination of the awl-carrier and peg-driver, each separately lifted by a cam, and driven down by a spring, substantially as described. This I find to have been a new device, and, if the machines sold by the defendant are, in substance, the same, in this respect, as that of Gallahue, then of this claim the defendant is an infringer. In the machine of Gallahue, as described in his original patent, there was, besides the springs, a weight co-operating therewith, to give greater efficiency to the blow; but the spring was there, also, acting, and the awl-carrier and peg-driver were raised by a cam. In the defendant's machine, the awl-carrier and peg-driver are raised by a cam; but the downward blow is given by the spring, without any additional weight. Hereupon, the 10

11 YesWeScan: The FEDERAL CASES questions arise, whether, when an inventor employed both spring and weight, in his machine, as originally constructed, he is at liberty to claim, in his reissue, the use of the spring alone, as included in his invention, and whether another person may use the spring alone without liability as an infringer. My conclusion, in this case, is, that the defendant was not at liberty to use the spring, and, by increasing its power, render it practically equivalent to both spring and weight as originally described. How far such a change, with a corresponding change in the details of the arrangement may be an improvement, to which the defendant or those whom he represents, have title, may depend upon the patentee's right to claim the spring separately, in his reissue; but, in my judgment, even if an improvement it is an infringement It is an appropriation of a substantial part of the actual invention shown in the original record. Nor do I perceive any sound objection to allowing the inventor, in his reissue, to claim the action of the spring alone. It is shown in the record of his patent; and, surely, a patentee, whose devices are new, is at liberty to claim each, by way of reissue, although he may have represented and claimed them originally as acting conjointly. In respect to this claim, therefore, I deem the machines sold by the defendant an infringement 3d. The next claim in this reissue, of which infringement is averred, is: The combination, in a pegging machine, of a gauge for the edge of the sole to rest against, and an awl-carrier driven by a spring, substantially as herein described. It was not claimed, by the complainants' counsel, on the hearing, that, if this claim be regarded simply as a claim to combination, as such, it was valid; and for this reason a gauge operated in the same manner, and produced the same effect, by whatever means the awl-carrier was driven, and the awl-carrier driven by a spring operated in the same manner, and produced the same effect by whatever means the boot or shoe was brought to the proper position for receiving the peg. In such case, (mere combination being the subject of the patent), the doctrine proceeds upon the ground, that the parts are old, and that nothing new results from their contiguous or contemporaneous action, which is due thereto. But, where one or more of the parts are new, and the combination is, for that reason, made to produce a new result, in the greater rapidity 11

12 GALLAHUE et al. v. BUTTERFIELD. and economy with which the shoe can he pegged, as, where the use of the new device of driving the awl-carrier by the spring made to operate automatically, or, in the terms of the claim, substantially as described, cannot be usefully employed without the gauge, then there is something more than mere aggregation, in the sense above stated. Then there is a new result, due to the employment of the awl-carrier, driven by a spring, and operating automatically, in connection with a gauge, without which it could not be operated to produce the advantageous results contemplated and, in fact, attained, by the use of both. All machines are, in a certain sense, combinations; but it is not true of machines, as such, that, because every one of its members performs in it the identical office which it would perform howsoever used, the conjoint action in their new combination may not produce a result new and useful, and never before attained. In this view, I deem this claim valid, and hold it infringed by the defendant. 4th. The next claim is: Making the gauge, (a,) against which the edge of the sole bears, adjustable, for the purpose of enabling the shoe to be so adjusted as to have two or more rows of pegs inserted therein. The Briggs hand machine had, as already stated, an adjustable gauge; but, it was only adapted to one change. This enabled the workman to insert two rows of pegs only; and it was not adjusted in the same manner as was that of Gallahue. The former was attached to the machine by a screw, which, being loosened, permitted it to be turned, so as to present to the edge of the shoe, first its longer, and then, its shorter, end. The gauge of Gallahue was attached by a screw, which, being loosened, permitted the gauge, (in which was a slot, through which the screw was inserted,) to be drawn forward, or pushed back, so as to regulate the insertion of pegs at any desired distance, nearer or more remote, from the edge of the sole. But this construction of a gauge was not novel, and the circumstance that it was here applied to a pegging machine, and guided the shoe, so that any number of rows of pegs could be inserted, does not make it patentable, except when used with other devices, so as to constitute either a new machine or a new and patentable combination. In such machine or combination, it may be a part of the complainants' invention, but the making of the gauge adjustable not being new, the mere application of it to a new use is not separately and independently patentable. Others of the claims of the patent may embrace all to which the patentee is entitled in respect to the use of the gauge, but, the claim to the mere making of the gauge adjustable, as expressed in this claim, I think, cannot be separately sustained. 5th. The remaining claim in this reissue is: The combination, in a pegging machine, of a gauge for the edge of the sole to bear against and a rotating last-bolder or support substantially as described. I cannot find that this claim is infringed by the defendant, unless I should hold that it embraces every combination in which a gauge is used, for the edge of the sole to bear 12

13 YesWeScan: The FEDERAL CASES against with a rotating last-holder. If I were so to hold, then I must find, from the evidence, that Lackey anticipated the complainants' and, if I hold that the claim is limited to the special device by which Gallahue effected the rotation, then I must find, from the evidence, that the defendant does not infringe. In either case, the complainants cannot prevail, in this case, upon this claim. 6th. The only infringement of the reissue of June 22d, 1869, relates to the second claim therein. The complainants insist that the last-holder connected with the machines sold by the defendant though widely different in form, does, by the use of merely mechanical equivalents, embrace, in principle and mode of operation, the substance of this second claim of Gallahue to his last-holder. That claim is: Pivoting the plate or frame, (g,) that supports the last, at or near its centre, and so arranging it that it may turn on said pivot during the operation of pegging, thereby so adjusting the boot or shoe as to present the various portions of the sole in the requisite position to the awl and peg, as the sole moves along, substantially as described. The specific details of the arrangement by which this result is automatically produced, are, some of them, the subject of other claims in this patent but it is not claimed that these details are copied in the defendant's machines. It is claimed, that supporting the last on a plate or frame pivoted at or near its centre, so as to allow an oscillating or vibratory motion of the last and to present the uneven and curved surface of the sole in proper position to the awl, at the very place of its descent, so that it shall pass in the proper direction into the leather, was new and a patentable device, and that in this particular, though without copying the supplemental means of moving the last forward and backward, by which such moving was automatically effected, the defendant has infringed the patent It will be perceived, that the pivoting here claimed, is entirely irrespective of the question, by what means, whether mechanical, or by the hand of the workman, the shoe resting on the holder is brought or held under the awl and peg-driver, and alike independent of the means by which it is moved along, so as to be pegged, from heel to toe, or from toe to heel, and it has no necessary connection with the instrumentality by which the shoe is to be rotated, so as to be pegged on both sides, and around heel and toe. All these are necessary to the full performance of the pegging, but they are not embraced in this claim. It is the raising and depressing of 13

14 GALLAHUE et al. v. BUTTERFIELD. heel and toe alternately, and the oscillation side-wise, so that the surface, at the point where the peg is to be inserted, may receive the awl and peg in the right direction, which this claim contemplates. Gallahue's device consists in placing his last-holder on pivots passing through an arm on each side, so that either end, by the oscillation of the holder on the pivot, raises or depresses either end of the last, as it is moved forward or backward. The sidewise vibratory motion is effected in like manner, by pivoting the bed of the last-holder at each end, so that it may be turned towards or from the awl, and so change the plane of the surface of the shoe lying thereon. In short, by this combination of pivots, something resembling a universal joint is produced, or, perhaps, more exactly, an arrangement like the usual mode of suspending a mariner's compass. Such an arrangement, applied to a pegging machine, was new in its operation and effect, in the art of pegging shoes, and its utility cannot be deemed doubtful, upon the proofs herein. The last-holder used in the machines sold by the defendant has the same operation, and in substantially the same mode. It is true, that some of the proofs would, at first view, indicate that the latter is not the equivalent of the complainants') device, but such evidence includes in its scope more than the claim now under consideration, as above explained. As it respects the applying of the shoe to the gauge, and holding it in contact, the hand and power of the workman is required. As it respects the moving of the shoe forward, and turning it around the heel and toe, the serrated instrument or feed, co-operating with the power of the workman applied to the last-holder, are necessary. But, as already remarked, these are not the features which are the subject of this claim. The vibratory and oscillating motion of the last, by the means of what is, in substance, a universal joint, is what this claim contemplates and provides for. It is urged, that, by the defendant's machine, operated, in this respect, partly by hand, the operation is more perfectly performed, that is, the surface of the shoe, at the point of the insertion of the peg, is more exactly at right angles to the line of the motion of the awl. That may, perhaps, be true, but that is due to the guiding power of the workman, employed instead of the automatic motion produced in the complainants' machine, and it is not those which are embraced in this claim. No prior machine had the capacity here in question. The Lackey machine moved the shoe in the arc of a circle, but had not two combined motions, producing the result referred to. Several last-holders, called jacks, had been contrived, but none had this important feature, as I think the evidence fully establishes. This claim must, therefore', be held infringed by the defendant. 7th. The other and remaining claim of which the complainants insist that infringement is shown, is in the patent dated August 26th, That claim is: Cutting off the pegs laterally from a strip of peg wood by the movable knife, (e,) being brought against the surface of v, figure 3, as set forth. 14

15 It is clear, I think, upon the evidence, that this was an original invention by Gallahue. Laying out of view, for reasons already stated, the machine of Whittemore, no evidence is produced of any prior device like that of Gallahue. All previous devices for cutting the strips of peg wood into pegs operated upon the edge of the strip, so as to split it, and, the grain of the wood being irregular, the split would follow the grain of the wood, and the pegs were of uneven and irregular form. By Gallahue's device, the knife, actuated by a lever, was made to bear upon, and penetrate, the strip of peg wood sidewise, and divide it into pegs of even, regular, and uniform size and form. By the like device in the machine sold by the defendant, operating substantially in the same manner, the pegs are cut evenly and regularly, without being affected by irregularity or obliquity in the grain of the wood. If there were any doubt in regard to other particulars, the infringement by the defendant in this seems to me clear. I have not overlooked or failed to consider the objections urged to these conclusions, in the very able argument of the defendant's counsel. The failure to notice them herein In detail is not due to a want of appreciation of the industry and ability displayed in their presentation. Having reached the conviction expressed in the foregoing, I have no alternative but to say, that the complainants are entitled to a decree in conformity therewith. 1 [Reported by Hon. Samuel Blatchford, District Judge, and by Samuel S. Fisher, Esq., and here compiled and reprinted by permission. The syllabus and opinion are from 10 Blatchf. 232, and the statement is from 6 Fish. Pat. Cas. 203; Merw. Pat Inv. 340, contains only a partial report.] 3 [From 6 Fish. Pat. Cas. 203.] 2 [From 6 Fish. Pat. Cas. 203.] YesWeScan: The FEDERAL CASES This volume of American Law was transcribed for use on the Internet 15 through a contribution from Google.

GROSJEAN V. PECK, STOW & WILCOX CO. ET AL. [11 Blatchf. 54; Merw. Pat. Inv. 342.] 1 Circuit Court, S. D. New York. March 19, 1873.

![GROSJEAN V. PECK, STOW & WILCOX CO. ET AL. [11 Blatchf. 54; Merw. Pat. Inv. 342.] 1 Circuit Court, S. D. New York. March 19, 1873. GROSJEAN V. PECK, STOW & WILCOX CO. ET AL. [11 Blatchf. 54; Merw. Pat. Inv. 342.] 1 Circuit Court, S. D. New York. March 19, 1873.](/thumbs/89/98067177.jpg) YesWeScan: The FEDERAL CASES GROSJEAN V. PECK, STOW & WILCOX CO. ET AL. Case No. 5,841. [11 Blatchf. 54; Merw. Pat. Inv. 342.] 1 Circuit Court, S. D. New York. March 19, 1873. PATENTS VALIDITY ANTICIPATION

YesWeScan: The FEDERAL CASES GROSJEAN V. PECK, STOW & WILCOX CO. ET AL. Case No. 5,841. [11 Blatchf. 54; Merw. Pat. Inv. 342.] 1 Circuit Court, S. D. New York. March 19, 1873. PATENTS VALIDITY ANTICIPATION

RUBBER TIP PENCIL CO. V. HOWARD ET AL. [9 Blatchf. 490; 5 Fish. Pat Cas. 377; 1 O. G. 407.] 1 Circuit Court, S. D. New York. March 19, 1872.

![RUBBER TIP PENCIL CO. V. HOWARD ET AL. [9 Blatchf. 490; 5 Fish. Pat Cas. 377; 1 O. G. 407.] 1 Circuit Court, S. D. New York. March 19, 1872. RUBBER TIP PENCIL CO. V. HOWARD ET AL. [9 Blatchf. 490; 5 Fish. Pat Cas. 377; 1 O. G. 407.] 1 Circuit Court, S. D. New York. March 19, 1872.](/thumbs/81/83107264.jpg) 1298 Case No. 12,102. RUBBER TIP PENCIL CO. V. HOWARD ET AL. [9 Blatchf. 490; 5 Fish. Pat Cas. 377; 1 O. G. 407.] 1 Circuit Court, S. D. New York. March 19, 1872. 2 PATENTS RUBBER PENCIL HEAD INVENTION.

1298 Case No. 12,102. RUBBER TIP PENCIL CO. V. HOWARD ET AL. [9 Blatchf. 490; 5 Fish. Pat Cas. 377; 1 O. G. 407.] 1 Circuit Court, S. D. New York. March 19, 1872. 2 PATENTS RUBBER PENCIL HEAD INVENTION.

Circuit Court, E. D. Wisconsin. June 14, 1881.

WOVEN WIRE MATTRESS CO. V. SIMMONS AND ANOTHER. Circuit Court, E. D. Wisconsin. June 14, 1881. 1. RE-ISSUED LETTERS PATENT No. 7,704 IMPROVEMENT IN BEDSTEAD FRAMES. In re-issued letters patent No. 7,704,

WOVEN WIRE MATTRESS CO. V. SIMMONS AND ANOTHER. Circuit Court, E. D. Wisconsin. June 14, 1881. 1. RE-ISSUED LETTERS PATENT No. 7,704 IMPROVEMENT IN BEDSTEAD FRAMES. In re-issued letters patent No. 7,704,

Circuit Court, D. Connecticut. January 16, 1882.

COES V. THE COLLINS CO. Circuit Court, D. Connecticut. January 16, 1882. 1. LETTERS PATENT WRENCHES INFRINGEMENT. The first claim of reissued letters patent No. 3, 483, granted to Loring Coes, June 1,

COES V. THE COLLINS CO. Circuit Court, D. Connecticut. January 16, 1882. 1. LETTERS PATENT WRENCHES INFRINGEMENT. The first claim of reissued letters patent No. 3, 483, granted to Loring Coes, June 1,

2010 Thomson Reuters. No Claim to Orig. US Gov. Works.

13 F. 456 Page 1 (Cite as: ) Circuit Court, N.D. New York. LULL v. CLARK and others. 1882. In Equity. PATENTS FOR INVENTIONS- FORMAL VARI- ATION- INFRINGEMENT. Where the mechanism used by defendant's shutter

13 F. 456 Page 1 (Cite as: ) Circuit Court, N.D. New York. LULL v. CLARK and others. 1882. In Equity. PATENTS FOR INVENTIONS- FORMAL VARI- ATION- INFRINGEMENT. Where the mechanism used by defendant's shutter

Circuit Court, N. D. Illinois. January 11, 1886.

256 v.26f, no.4-17 FLORSHEIM AND ANOTHER V. SCHILLING. 1 Circuit Court, N. D. Illinois. January 11, 1886. 1. PATENTS FOR INVENTIONS CORSETS. Letters patent No. 238,100 corsets, and No. 238,101, elastic

256 v.26f, no.4-17 FLORSHEIM AND ANOTHER V. SCHILLING. 1 Circuit Court, N. D. Illinois. January 11, 1886. 1. PATENTS FOR INVENTIONS CORSETS. Letters patent No. 238,100 corsets, and No. 238,101, elastic

WOODWARD V. DINSMORE. [4 Fish. Pat. Cas. 163; Merw. Pat. Inv. 430.] 1 Circuit Court, D. Maryland. Feb., 1870.

![WOODWARD V. DINSMORE. [4 Fish. Pat. Cas. 163; Merw. Pat. Inv. 430.] 1 Circuit Court, D. Maryland. Feb., 1870. WOODWARD V. DINSMORE. [4 Fish. Pat. Cas. 163; Merw. Pat. Inv. 430.] 1 Circuit Court, D. Maryland. Feb., 1870.](/thumbs/90/101824678.jpg) YesWeScan: The FEDERAL CASES WOODWARD V. DINSMORE. Case No. 18,003. [4 Fish. Pat. Cas. 163; Merw. Pat. Inv. 430.] 1 Circuit Court, D. Maryland. Feb., 1870. PATENT FOR INVENTION SOLAR CAMERA REISSUED PATENT

YesWeScan: The FEDERAL CASES WOODWARD V. DINSMORE. Case No. 18,003. [4 Fish. Pat. Cas. 163; Merw. Pat. Inv. 430.] 1 Circuit Court, D. Maryland. Feb., 1870. PATENT FOR INVENTION SOLAR CAMERA REISSUED PATENT

Circuit Court, D. Connecticut. April 14, 1885.

587 HARTFORD WOVEN-WIRE MATTRESS CO. V. PEERLESS WIRE MATTRESS CO. Circuit Court, D. Connecticut. April 14, 1885. 1. PATENTS FOR INVENTIONS WIRE MATTRESSES FARNHAM PATENT REISSUE NO. 7,704 NOVELTY. Reissued

587 HARTFORD WOVEN-WIRE MATTRESS CO. V. PEERLESS WIRE MATTRESS CO. Circuit Court, D. Connecticut. April 14, 1885. 1. PATENTS FOR INVENTIONS WIRE MATTRESSES FARNHAM PATENT REISSUE NO. 7,704 NOVELTY. Reissued

made of a fabric composed of paper and muslin, or of

672 Case 24FED.CAS. 43 No. 14,395. UNION PAPER-COLLAR CO. V. VAN DEUSEN ET AL. [10 Blatchf. 109; 5 Fish. Pat. Cas. 597; 2 O. G. 361; Merw. Pat. Inv. 335.] 1 Circuit Court, S. D. New York. Aug. 27, 1872.

672 Case 24FED.CAS. 43 No. 14,395. UNION PAPER-COLLAR CO. V. VAN DEUSEN ET AL. [10 Blatchf. 109; 5 Fish. Pat. Cas. 597; 2 O. G. 361; Merw. Pat. Inv. 335.] 1 Circuit Court, S. D. New York. Aug. 27, 1872.

Double-lift Jacquard mechanism

United States Patent: 4,416,310 1/20/03 4:08 PM ( 102 of 131 ) United States Patent 4,416,310 Sage November 22, 1983 Double-lift Jacquard mechanism Abstract A double-lift Jacquard mechanism in which the

United States Patent: 4,416,310 1/20/03 4:08 PM ( 102 of 131 ) United States Patent 4,416,310 Sage November 22, 1983 Double-lift Jacquard mechanism Abstract A double-lift Jacquard mechanism in which the

Circuit Court, N. D. Illinois. August 9, 1884.

648 ADAMS & WESTLAKE MANUF'G CO. V. WILSON PACKING CO. AND OTHERS. Circuit Court, N. D. Illinois. August 9, 1884. 1. PATENTS FOR INVENTIONS SOLDERING PROCESS NOVELTY. Patent 191,405, granted to George

648 ADAMS & WESTLAKE MANUF'G CO. V. WILSON PACKING CO. AND OTHERS. Circuit Court, N. D. Illinois. August 9, 1884. 1. PATENTS FOR INVENTIONS SOLDERING PROCESS NOVELTY. Patent 191,405, granted to George

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION PREPARATION FOR OPERATION CAUTIONS ON USE OPERATION

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION ------------------------------------- 1 PREPARATION FOR OPERATION 1. Adjustment of needle bar stop position ---------------------------------------------------------

CONTENTS PRECAUTIONS BEFORE STARTING OPERATION ------------------------------------- 1 PREPARATION FOR OPERATION 1. Adjustment of needle bar stop position ---------------------------------------------------------

United States Patent (19) Lund

United States Patent (19) Lund 54 BROACHING CUTTER 76 Inventor: David R. Lund, 1823 Cornish Ave., Charleston, S.C. 29412 21 Appl. No.: 903,157 22 Filed: Jul. 30, 1997 Related U.S. Application Data 62 Division

United States Patent (19) Lund 54 BROACHING CUTTER 76 Inventor: David R. Lund, 1823 Cornish Ave., Charleston, S.C. 29412 21 Appl. No.: 903,157 22 Filed: Jul. 30, 1997 Related U.S. Application Data 62 Division

BADISCHE ANILIN & SODA FABRIK V. CUMMINS. [4 Ban. & A. 489.] 1 Circuit Court, D. Massachusetts. Sept, 1879.

![BADISCHE ANILIN & SODA FABRIK V. CUMMINS. [4 Ban. & A. 489.] 1 Circuit Court, D. Massachusetts. Sept, 1879. BADISCHE ANILIN & SODA FABRIK V. CUMMINS. [4 Ban. & A. 489.] 1 Circuit Court, D. Massachusetts. Sept, 1879.](/thumbs/76/73872500.jpg) YesWeScan: The FEDERAL CASES BADISCHE ANILIN & SODA FABRIK V. CUMMINS. Case No. 720. [4 Ban. & A. 489.] 1 Circuit Court, D. Massachusetts. Sept, 1879. PATENTS FOR INVENTIONS INFRINGEMENT NEW PROCESS OF

YesWeScan: The FEDERAL CASES BADISCHE ANILIN & SODA FABRIK V. CUMMINS. Case No. 720. [4 Ban. & A. 489.] 1 Circuit Court, D. Massachusetts. Sept, 1879. PATENTS FOR INVENTIONS INFRINGEMENT NEW PROCESS OF

No. 412, 414, 416 Operations Manual

No. 412, 414, 416 Operations Manual CARE: Occasional oiling of moving parts with machine oil will ease operation and extend the life of the brake. Occasionally check and tighten the lower beam bracket

No. 412, 414, 416 Operations Manual CARE: Occasional oiling of moving parts with machine oil will ease operation and extend the life of the brake. Occasionally check and tighten the lower beam bracket

United States Patent 19 Couture et al.

United States Patent 19 Couture et al. 54 VEGETABLE PEELINGAPPARATUS 76 Inventors: Fernand Couture; René Allard, both of 2350 Edouard-Montpetit Blvd., Montreal, Quebec, Canada, H3T 1J4 21 Appl. No.: 805,985

United States Patent 19 Couture et al. 54 VEGETABLE PEELINGAPPARATUS 76 Inventors: Fernand Couture; René Allard, both of 2350 Edouard-Montpetit Blvd., Montreal, Quebec, Canada, H3T 1J4 21 Appl. No.: 805,985

OPERATING INSTRUCTIONS 3421UX VETERANS BLVD, CARLSTADT, NJ 07072

OPERATING INSTRUCTIONS 3421UX5-1 400 VETERANS BLVD, CARLSTADT, NJ 07072 CONTENTS DESCRIPTION... 3 OPERATOR INFORMATION... 5-8 INSTALLATION...... 4 ADJUSTMENT... 8-17 LUBRICATION... 5 INDEX Description

OPERATING INSTRUCTIONS 3421UX5-1 400 VETERANS BLVD, CARLSTADT, NJ 07072 CONTENTS DESCRIPTION... 3 OPERATOR INFORMATION... 5-8 INSTALLATION...... 4 ADJUSTMENT... 8-17 LUBRICATION... 5 INDEX Description

JUMBO STENCIL CUTTING MACHINE PARTS LIST AND OPERATING MANUAL

JUMBO STENCIL CUTTING MACHINE PARTS LIST AND OPERATING MANUAL Marion, IL USA STK. NO. 5800-152, REV A Warning: This machine contains pinch points which can injure personnel when not used properly. This

JUMBO STENCIL CUTTING MACHINE PARTS LIST AND OPERATING MANUAL Marion, IL USA STK. NO. 5800-152, REV A Warning: This machine contains pinch points which can injure personnel when not used properly. This

United States Patent (19.

United States Patent (19. Etcheverry (54) BUTTERFLY VALVE (75) Inventor: John P. Etcheverry, Sylmar, Calif. 73) Assignee: International Telephone and Telegraph Corporation, New York, N.Y. 21 Appl. No.:

United States Patent (19. Etcheverry (54) BUTTERFLY VALVE (75) Inventor: John P. Etcheverry, Sylmar, Calif. 73) Assignee: International Telephone and Telegraph Corporation, New York, N.Y. 21 Appl. No.:

Circuit Court, N. D. New York. June 26, 1890.

YesWeScan: The FEDERAL REPORTER STEAM GAUGE & LANTERN CO. V. WILLIAMS. Circuit Court, N. D. New York. June 26, 1890. 1. PATENTS FOR INVENTIONS LOCOMOTIVE HEAD-LIGHTS INFRINGEMENT. The first claim of letters

YesWeScan: The FEDERAL REPORTER STEAM GAUGE & LANTERN CO. V. WILLIAMS. Circuit Court, N. D. New York. June 26, 1890. 1. PATENTS FOR INVENTIONS LOCOMOTIVE HEAD-LIGHTS INFRINGEMENT. The first claim of letters

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, (Applicatioxg filed Jan. 27, 1899.

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, 81.0. (Applicatioxg filed Jan. 27, 1899.) ' (No Model.) 2 s_heets-sheet l. ó» y@ gw/q. Nn. 635,225.. f Patentad

No. 635,225. Patented Oct. I7, 899. W. A. VAN BERKEL. MACHINE FOB SLICING GERMAN SAUSAGES, 81.0. (Applicatioxg filed Jan. 27, 1899.) ' (No Model.) 2 s_heets-sheet l. ó» y@ gw/q. Nn. 635,225.. f Patentad

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030085640A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0085640 A1 Chan (43) Pub. Date: May 8, 2003 (54) FOLDABLE CABINET Publication Classification (76) Inventor:

US 20030085640A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0085640 A1 Chan (43) Pub. Date: May 8, 2003 (54) FOLDABLE CABINET Publication Classification (76) Inventor:

Sales and Service

OPERATION MANUAL / SPARE PARTS LIST MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A333 13.2370.01 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 WARRANTY CONDITIONS AND LIABILITY 3 3 APPROPRIATE USE 3 4 TECNICAL DATA

OPERATION MANUAL / SPARE PARTS LIST MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A333 13.2370.01 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 WARRANTY CONDITIONS AND LIABILITY 3 3 APPROPRIATE USE 3 4 TECNICAL DATA

Jacquard -harness of a weaving machine

Wednesday, December 26, 2001 United States Patent: 4,057,084 Page: 1 ( 251 of 266 ) United States Patent 4,057,084 Mueller November 8, 1977 Jacquard -harness of a weaving machine Abstract An improvement

Wednesday, December 26, 2001 United States Patent: 4,057,084 Page: 1 ( 251 of 266 ) United States Patent 4,057,084 Mueller November 8, 1977 Jacquard -harness of a weaving machine Abstract An improvement

SERVICE MANUAL FOR HOMELOCK M1034D 2034D 1134DW 1134D

SERVICE MANUAL FOR HOMELOCK M1034D 2034D 1134DW 1134D 11.2000 2.2012 I HOW TO USE THIS MANUAL... 1 II HOW TO ADJUST... 2 1. Height of needle bar... 2 2. Position of the lowerlooper... 3 3. Timing of the

SERVICE MANUAL FOR HOMELOCK M1034D 2034D 1134DW 1134D 11.2000 2.2012 I HOW TO USE THIS MANUAL... 1 II HOW TO ADJUST... 2 1. Height of needle bar... 2 2. Position of the lowerlooper... 3 3. Timing of the

John J. Vaillancourt Steven L. Camara Daniel W. French NOTICE

Serial Number Filing Date Inventor 09/152.475 11 September 1998 John J. Vaillancourt Steven L. Camara Daniel W. French NOTICE The above identified patent application is available for licensing. Requests

Serial Number Filing Date Inventor 09/152.475 11 September 1998 John J. Vaillancourt Steven L. Camara Daniel W. French NOTICE The above identified patent application is available for licensing. Requests

DISTRIBUTION STATEMENT A Approved for Public Release Distribution Unlimited

Serial Number 09/152.477 Filing Date 11 September 1998 Inventor Anthony A. Ruffa NOTICE The above identified patent application is available for licensing. Requests for information should be addressed

Serial Number 09/152.477 Filing Date 11 September 1998 Inventor Anthony A. Ruffa NOTICE The above identified patent application is available for licensing. Requests for information should be addressed

William H. Nedderman, Jr. NOTICE. The above identified patent application is available for licensing. Requests for information should be addressed to:

_ _ Serial Number Filing Date Inventor 09/332,407 14 June 1999 William H. Nedderman, Jr. NOTICE The above identified patent application is available for licensing. Requests for information should be addressed

_ _ Serial Number Filing Date Inventor 09/332,407 14 June 1999 William H. Nedderman, Jr. NOTICE The above identified patent application is available for licensing. Requests for information should be addressed

MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A332

OPERATION MANUAL / SPARE PARTS LIST MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A332 13.2250.01 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 WARRANTY CONDITIONS AND LIABILITY 3 3 APPROPRIATE USE 3 4 TECNICAL DATA

OPERATION MANUAL / SPARE PARTS LIST MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A332 13.2250.01 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 WARRANTY CONDITIONS AND LIABILITY 3 3 APPROPRIATE USE 3 4 TECNICAL DATA

TRAINING BULLETIN FORCIBLE ENTRY 1 March 15, 1997 FORCIBLE ENTRY TABLE OF CONTENTS. 1. Introduction. 2. Doors-Inward Opening. 3. Doors-Outward Opening

TRAINING BULLETIN 1 March 15, 1997 TABLE OF CONTENTS 1. Introduction 2. Doors-Inward Opening 3. Doors-Outward Opening 4. Through The Lock Method 5. Padlocks 6. American Lock Series 2000 7. Bars And Sliding

TRAINING BULLETIN 1 March 15, 1997 TABLE OF CONTENTS 1. Introduction 2. Doors-Inward Opening 3. Doors-Outward Opening 4. Through The Lock Method 5. Padlocks 6. American Lock Series 2000 7. Bars And Sliding

MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A335

OPERATION MANUAL / SPARE PARTS LIST MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A335 13.2810.01 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 WARRANTY CONDITIONS AND LIABILITY 3 3 APPROPRIATE USE 3 4 TECNICAL DATA

OPERATION MANUAL / SPARE PARTS LIST MANUAL SEALLESS STEEL STRAPPING TOOL MODEL A335 13.2810.01 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 WARRANTY CONDITIONS AND LIABILITY 3 3 APPROPRIATE USE 3 4 TECNICAL DATA

Anderson s Stone Dresser

Anderson s Stone Dresser In Scientific American, Vol. XXV, No. 15 New York, October 7, 1871, pp. 223 This article, which begins on the next page, is presented on the Stone Quarries and Beyond web site.

Anderson s Stone Dresser In Scientific American, Vol. XXV, No. 15 New York, October 7, 1871, pp. 223 This article, which begins on the next page, is presented on the Stone Quarries and Beyond web site.

Leno selvedge device and method of forming a leno selvedge

Friday, December 28, 2001 United States Patent: 3,945,406 Page: 1 ( 1 of 1 ) United States Patent 3,945,406 Wueger March 23, 1976 Leno selvedge device and method of forming a leno selvedge Abstract A leno

Friday, December 28, 2001 United States Patent: 3,945,406 Page: 1 ( 1 of 1 ) United States Patent 3,945,406 Wueger March 23, 1976 Leno selvedge device and method of forming a leno selvedge Abstract A leno

================================================================= Date of the judgement

Date of the judgement 1986.10.03 Case Number 1986(O)454 Reporter Minshu Vol.40, No.6, at 1068 Title Judgment upon the case concerning the meaning of the 'preparation for business to work the invention'

Date of the judgement 1986.10.03 Case Number 1986(O)454 Reporter Minshu Vol.40, No.6, at 1068 Title Judgment upon the case concerning the meaning of the 'preparation for business to work the invention'

Brochure Includes: Set-up Instructions Operating Instructions Parts List Fundamentals of Drill Sharpening. Patent 3,952,459

Patent 3,952,459 Brochure Includes: Set-up Instructions Operating Instructions Parts List Fundamentals of Drill Sharpening Accurately Sharpens most drills bits. Now, with this one low-cost, simple machine,

Patent 3,952,459 Brochure Includes: Set-up Instructions Operating Instructions Parts List Fundamentals of Drill Sharpening Accurately Sharpens most drills bits. Now, with this one low-cost, simple machine,

Warp length compensator for a triaxial weaving machine

United States Patent: 4,170,249 2/15/03 8:18 AM ( 1 of 1 ) United States Patent 4,170,249 Trost October 9, 1979 Warp length compensator for a triaxial weaving machine Abstract A fixed cam located between

United States Patent: 4,170,249 2/15/03 8:18 AM ( 1 of 1 ) United States Patent 4,170,249 Trost October 9, 1979 Warp length compensator for a triaxial weaving machine Abstract A fixed cam located between

RlGIDITY AND STRENGTH OF WALL FRAMES BRACED WlTH METAL STRAPPING

RlGIDITY AND STRENGTH OF WALL FRAMES BRACED WlTH METAL STRAPPING information Reviewed and Reaffirmed March 1955 No. R1603 UNITED STATES DEPARTMENT OF AGRICULTURE FOREST SERVICE FOREST PRODUCTS LABORATORY

RlGIDITY AND STRENGTH OF WALL FRAMES BRACED WlTH METAL STRAPPING information Reviewed and Reaffirmed March 1955 No. R1603 UNITED STATES DEPARTMENT OF AGRICULTURE FOREST SERVICE FOREST PRODUCTS LABORATORY

(12) United States Patent

USOO7325359B2 (12) United States Patent Vetter (10) Patent No.: (45) Date of Patent: Feb. 5, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) PROJECTION WINDOW OPERATOR Inventor: Gregory J. Vetter,

USOO7325359B2 (12) United States Patent Vetter (10) Patent No.: (45) Date of Patent: Feb. 5, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) PROJECTION WINDOW OPERATOR Inventor: Gregory J. Vetter,

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE. . _ LAWN MOWER. N0.'554,081. Patented Feb. 4, $5 9; Em ;! \ g/ F

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE.. _ LAWN MOWER. N0.'554,081. Patented Feb. 4, 1896. H $5 9; Em ;! \ g/ F % (No Model.) E. W. MCGUIRE. LAWN MOWER. a" Sheets-Sheet 2, No. 554,081. PéJtentedI'eb.

(No Model.) _ a Sheets-Sheet 1. E. W. 'MOGUIRE.. _ LAWN MOWER. N0.'554,081. Patented Feb. 4, 1896. H $5 9; Em ;! \ g/ F % (No Model.) E. W. MCGUIRE. LAWN MOWER. a" Sheets-Sheet 2, No. 554,081. PéJtentedI'eb.

Simplex Studio. Model 700-S MAT CUTTER INSTRUCTION AND OPERATION MANUAL

Model 700-S Simplex Studio 22 1 /2" Mat cutting system with production stops, parallel mat guide, flush cut squaring arm, including straight and bevel cutting heads. MAT CUTTER www.logangraphic.com For

Model 700-S Simplex Studio 22 1 /2" Mat cutting system with production stops, parallel mat guide, flush cut squaring arm, including straight and bevel cutting heads. MAT CUTTER www.logangraphic.com For

Thursday, August 22, 2002 United States Patent: 4,008,643 Page: 1. United States Patent 4,008,643 Young February 22, 1977.

Thursday, August 22, 2002 United States Patent: 4,008,643 Page: 1 ( 111 of 113 ) United States Patent 4,008,643 Young February 22, 1977 Knotless tatting Abstract A method is disclosed for performing lace

Thursday, August 22, 2002 United States Patent: 4,008,643 Page: 1 ( 111 of 113 ) United States Patent 4,008,643 Young February 22, 1977 Knotless tatting Abstract A method is disclosed for performing lace

Sketching Fundamentals

Sketching Fundamentals Learning Outcome When you complete this module you will be able to: Make basic engineering sketches of plant equipment. Learning Objectives Here is what you will be able to do when

Sketching Fundamentals Learning Outcome When you complete this module you will be able to: Make basic engineering sketches of plant equipment. Learning Objectives Here is what you will be able to do when

No. 622,774. Patented Apr. 1, 1899.

No. 622,774. Patented Apr. 1, 1899. J. M. MACLUCH. METHOD OF MANUFACTURING INDIA RUBBER OR OTHER ENDLESS BANDS OR STRIPS. (Application filed Oct. 4, 1898. (No Model.) 3 Sheets-Sheet 1. tenorris Peters

No. 622,774. Patented Apr. 1, 1899. J. M. MACLUCH. METHOD OF MANUFACTURING INDIA RUBBER OR OTHER ENDLESS BANDS OR STRIPS. (Application filed Oct. 4, 1898. (No Model.) 3 Sheets-Sheet 1. tenorris Peters

24 GA. PITTS ROLLFORMER

1 TIN KNOCKER 24 GA. PITTS ROLLFORMER INSTRUCTIONS & PARTS DIAGRAM Shown with Stand and Optional Flanging Attachment Rev. 092606 TAAG MACHINERY CO. (Master Distributor) 1257-B Activity Dr. Vista, CA 92081

1 TIN KNOCKER 24 GA. PITTS ROLLFORMER INSTRUCTIONS & PARTS DIAGRAM Shown with Stand and Optional Flanging Attachment Rev. 092606 TAAG MACHINERY CO. (Master Distributor) 1257-B Activity Dr. Vista, CA 92081

ROOP LAL Unit-6 Shaper & Planer Mechanical Engineering Department

Notes: shapers and planers Basic Mechanical Engineering (Part B ) 1 Introduction: Both shapers and planers are machine tools which produce a flat surface. They are capable of machining a horizontal, vertical

Notes: shapers and planers Basic Mechanical Engineering (Part B ) 1 Introduction: Both shapers and planers are machine tools which produce a flat surface. They are capable of machining a horizontal, vertical

# in 1 Metal Worker Auxiliary Operating Instructions

340 Snyder Avenue, Berkeley Heights, NJ 07922 www.micromark.com MMTechService@micromark.com Tech Support: 908-464-1094, weekdays, 1pm to 5 pm ET #86556 3 in 1 Metal Worker Auxiliary Operating Instructions

340 Snyder Avenue, Berkeley Heights, NJ 07922 www.micromark.com MMTechService@micromark.com Tech Support: 908-464-1094, weekdays, 1pm to 5 pm ET #86556 3 in 1 Metal Worker Auxiliary Operating Instructions

Occupational Safety, Health and Welfare (Woodworking Machines) Regulations 1989

Occupational Safety, Health and Welfare (Woodworking Machines) Regulations 1989 GN 66/1989 THE OCCUPATIONAL SAFETY, HEALTH AND WELFARE ACT 1988 Regulations made by the Minister under section 80(1) of the

Occupational Safety, Health and Welfare (Woodworking Machines) Regulations 1989 GN 66/1989 THE OCCUPATIONAL SAFETY, HEALTH AND WELFARE ACT 1988 Regulations made by the Minister under section 80(1) of the

CARPENTRY. Carpentry tools: The following are the tools that are made use of in all the wood working operations.

CARPENTRY INTRODUCTION: Carpentry may be defined as the process of making wooden components. It starts from a marketable form of wood and ends with a finished product. It Deals with the building work,

CARPENTRY INTRODUCTION: Carpentry may be defined as the process of making wooden components. It starts from a marketable form of wood and ends with a finished product. It Deals with the building work,

Circuit Court, S. D. New York. Dec. 29, 1860.

YesWeScan: The FEDERAL CASES Case No. 3,746. [4 Blatchf. 478.] 1 DE FOREST ET AL. V. REDFIELD. Circuit Court, S. D. New York. Dec. 29, 1860. CUSTOMS DUTIES DEPRECIATED FOREIGN CURRENCY REGULATIONS BY PRESIDENT

YesWeScan: The FEDERAL CASES Case No. 3,746. [4 Blatchf. 478.] 1 DE FOREST ET AL. V. REDFIELD. Circuit Court, S. D. New York. Dec. 29, 1860. CUSTOMS DUTIES DEPRECIATED FOREIGN CURRENCY REGULATIONS BY PRESIDENT

Motorized M3 AX7200 Rotary-Style Gasket Cutter Operating Instructions

Motorized M3 AX7200 Rotary-Style Gasket Cutter Operating Instructions INTRODUCTION Congratulations! You are the owner of the finest rotary-style gasket cutter in the world. Originally developed and patented

Motorized M3 AX7200 Rotary-Style Gasket Cutter Operating Instructions INTRODUCTION Congratulations! You are the owner of the finest rotary-style gasket cutter in the world. Originally developed and patented

TO OPERATE AUTO-GUIDE POWER. 24 Gauge Pittsburgh Operating Instructions FLANGING ATTACHMENT

24 Gauge Pittsburgh Operating Instructions Holding the material against the angle gauge slide it into the forming head. Be sure that the material remains against the gauge until work is finished. Make

24 Gauge Pittsburgh Operating Instructions Holding the material against the angle gauge slide it into the forming head. Be sure that the material remains against the gauge until work is finished. Make

Lumber Smith. Assembly Manual. If you are having problems assembling the saw and need assistance, please contact us at:

Lumber Smith Assembly Manual If you are having problems assembling the saw and need assistance, please contact us at: 804-577-7398 info@lumbersmith.com 1 Step 1 Safety Carefully read the Owners Manual.

Lumber Smith Assembly Manual If you are having problems assembling the saw and need assistance, please contact us at: 804-577-7398 info@lumbersmith.com 1 Step 1 Safety Carefully read the Owners Manual.

4. PRESS AND PRESS WORK

4. PRESS AND PRESS WORK Q. Which are the materials used for press work? GALVANISED IRON Zinc-coated iron is known as "galvanised iron"'. This soft steel sheet is popularly known as Gl sheet. Applications:

4. PRESS AND PRESS WORK Q. Which are the materials used for press work? GALVANISED IRON Zinc-coated iron is known as "galvanised iron"'. This soft steel sheet is popularly known as Gl sheet. Applications:

Striking with the cheek of the hammer instead of the face. Using the claws of the hammer for work that is best done with a wrecking bar.

The most important consideration is the squareness of the hammer head to the nail at the moment of impact. Sometimes in order to get a nail started, it is convenient to grip the handle closer to the head.

The most important consideration is the squareness of the hammer head to the nail at the moment of impact. Sometimes in order to get a nail started, it is convenient to grip the handle closer to the head.

AN IMPROVED VANDERWILT ROCK SAW G. D. Eurcn, Uniaersity of Arizona, Tucson, Arizona.

AN IMPROVED VANDERWILT ROCK SAW G. D. Eurcn, Uniaersity of Arizona, Tucson, Arizona. A simple and inexpensive device for sawing rock specimens up to 7 inches square in cross section was designed and described

AN IMPROVED VANDERWILT ROCK SAW G. D. Eurcn, Uniaersity of Arizona, Tucson, Arizona. A simple and inexpensive device for sawing rock specimens up to 7 inches square in cross section was designed and described

United States Patent (19)

United States Patent (19) Negley 54 DRILL GRINDER 75) Inventor: Marvin C. Negley, Clarinda, Iowa 73) Assignee: Lisle Corporation, Clarinda, Iowa 22 Filed: Oct. 29, 1974 (21) Appl. No.: 518,757 (52) U.S.

United States Patent (19) Negley 54 DRILL GRINDER 75) Inventor: Marvin C. Negley, Clarinda, Iowa 73) Assignee: Lisle Corporation, Clarinda, Iowa 22 Filed: Oct. 29, 1974 (21) Appl. No.: 518,757 (52) U.S.

V-Groover SIMPLEX INSTRUCTION AND OPERATION MANUAL M O DEL 703. For best results use only authentic Logan blades.

www.logangraphic.com SIMPLEX M O DEL 703 INSTRUCTION AND OPERATION MANUAL For best results use only authentic Logan blades CAUTION: BLADES EXTREMELY SHARP Use replacement blades #1258 Logan Graphic Products,

www.logangraphic.com SIMPLEX M O DEL 703 INSTRUCTION AND OPERATION MANUAL For best results use only authentic Logan blades CAUTION: BLADES EXTREMELY SHARP Use replacement blades #1258 Logan Graphic Products,

ROOP LAL Unit-6 Lathe (Turning) Mechanical Engineering Department

Notes: Lathe (Turning) Basic Mechanical Engineering (Part B) 1 Introduction: In previous Lecture 2, we have seen that with the help of forging and casting processes, we can manufacture machine parts of

Notes: Lathe (Turning) Basic Mechanical Engineering (Part B) 1 Introduction: In previous Lecture 2, we have seen that with the help of forging and casting processes, we can manufacture machine parts of

Trial decision. Conclusion The demand for trial of the case was groundless. The costs in connection with the trial shall be borne by the demandant.

Trial decision Invalidation No. 2014-800151 Aichi, Japan Demandant ELMO CO., LTD Aichi, Japan Patent Attorney MIYAKE, Hajime Gifu, Japan Patent Attorney ARIGA, Masaya Tokyo, Japan Demandee SEIKO EPSON

Trial decision Invalidation No. 2014-800151 Aichi, Japan Demandant ELMO CO., LTD Aichi, Japan Patent Attorney MIYAKE, Hajime Gifu, Japan Patent Attorney ARIGA, Masaya Tokyo, Japan Demandee SEIKO EPSON

MANUAL PLASTIC STRAPPING TOOL MODEL P404

OPERATION MANUAL / SPARE PARTS LIST MANUAL PLASTIC STRAPPING TOOL MODEL P404 43.0404.02 43040402.en/MAS/ 12.05 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 TECHNICAL DATA 3 3 OPERATION ELEMENTS 4 4 ADJUSTMENT

OPERATION MANUAL / SPARE PARTS LIST MANUAL PLASTIC STRAPPING TOOL MODEL P404 43.0404.02 43040402.en/MAS/ 12.05 INDEX PAGE 1 SAFETY INSTRUCTIONS 2 2 TECHNICAL DATA 3 3 OPERATION ELEMENTS 4 4 ADJUSTMENT

1,502, Boaz, only 22, MARIONETTE M. M. DONDO 27 A/ %- - IA WEATOR

only 22, 1924. t M. M. DONDO MARIONETTE Filed July 1, 1922 3. Sheets-Sheet l - IA WEATOR s alfull-.. 27 Boaz, 27 A/ %- Y.f iii).* d July 22, 1924 e M. M. DONDO MARIONETTE Filled July l, 1922 3 Sheets-Sheet

only 22, 1924. t M. M. DONDO MARIONETTE Filed July 1, 1922 3. Sheets-Sheet l - IA WEATOR s alfull-.. 27 Boaz, 27 A/ %- Y.f iii).* d July 22, 1924 e M. M. DONDO MARIONETTE Filled July l, 1922 3 Sheets-Sheet

(12) United States Patent (10) Patent No.: US 6,385,876 B1

USOO6385876B1 (12) United States Patent (10) Patent No.: McKenzie () Date of Patent: May 14, 2002 (54) LOCKABLE LICENSE PLATE COVER 2,710,475 A 6/1955 Salzmann... /202 ASSEMBLY 3,304,642 A 2/1967 Dardis...

USOO6385876B1 (12) United States Patent (10) Patent No.: McKenzie () Date of Patent: May 14, 2002 (54) LOCKABLE LICENSE PLATE COVER 2,710,475 A 6/1955 Salzmann... /202 ASSEMBLY 3,304,642 A 2/1967 Dardis...

FABA. Installation Instructions. Conductor Bar System. Publication #FABA-03 3/1/04 Part Number: Copyright 2004 Electromotive Systems

FABA Conductor Bar System Installation Instructions Publication #FABA-03 3/1/04 Part Number: 005-1062 Copyright 2004 Electromotive Systems 1S 100 Z Installation Instructions Contents: Basic Diagram - -

FABA Conductor Bar System Installation Instructions Publication #FABA-03 3/1/04 Part Number: 005-1062 Copyright 2004 Electromotive Systems 1S 100 Z Installation Instructions Contents: Basic Diagram - -

16U288 SINGER' SEWING MACHINE. From the library of: Superior I Sewing Machine & Supply LLC INSTRUCTIONS. Form UIO3 (Rev, 377)., THE SINGER COMPANY

iiv^- Form UIO3 (Rev, 377)., INSTRUCTIONS FOR USING AND ADJUSTING SINGER' SEWING MACHINE 16U288 THE SINGER COMPANY From the library of: Superior I Sewing Machine & Supply LLC CONTENTS PAGE DESCRIPTION

iiv^- Form UIO3 (Rev, 377)., INSTRUCTIONS FOR USING AND ADJUSTING SINGER' SEWING MACHINE 16U288 THE SINGER COMPANY From the library of: Superior I Sewing Machine & Supply LLC CONTENTS PAGE DESCRIPTION

SIMPLEX ELITE MAT CUTTER

INSTRUCTION MANUAL MODEL 750-1 / 760-1 SIMPLEX ELITE MAT CUTTER INSTRUCTIONS AND OPERATION MANUAL 40 in (101 cm) mat cutting system with bevel & straight cutters, production stops, 27 in (68 cm) squaring

INSTRUCTION MANUAL MODEL 750-1 / 760-1 SIMPLEX ELITE MAT CUTTER INSTRUCTIONS AND OPERATION MANUAL 40 in (101 cm) mat cutting system with bevel & straight cutters, production stops, 27 in (68 cm) squaring

Symbols used. Move the part in the direction of the arrow. Set the clearance as indicated. Move the part to its highest or lowest position.

4.1999. This service manual was compiled for use when repairing the XL5300, 5200, 5100, 5030, 5020, 5010,PX300,200,100 Zigzag Stitch Sewing Machines. Use this manual, together with the Parts Catalog, when

4.1999. This service manual was compiled for use when repairing the XL5300, 5200, 5100, 5030, 5020, 5010,PX300,200,100 Zigzag Stitch Sewing Machines. Use this manual, together with the Parts Catalog, when

PEARL DRUM PEDAL. Instruction Manual

PEARL DRUM PEDAL Instruction Manual Congratulations on your purchase! To get optimum performance of your "P-3002D" Drum Pedal, please read this Instruction Manual before playing. Drive Shaft Assembly Drive

PEARL DRUM PEDAL Instruction Manual Congratulations on your purchase! To get optimum performance of your "P-3002D" Drum Pedal, please read this Instruction Manual before playing. Drive Shaft Assembly Drive

DEPARTMENT OF THE NAVY. The below identified patent application is available for licensing. Requests for information should be addressed to:

DEPARTMENT OF THE NAVY OFFICE OF COUNSEL NAVAL UNDERSEA WARFARE CENTER DIVISION 1176 HOWELL STREET NEWPORT Rl 02841-1708 IN REPLY REFER TO: Attorney Docket No. 82649 Date: 23 September 2004 The below identified

DEPARTMENT OF THE NAVY OFFICE OF COUNSEL NAVAL UNDERSEA WARFARE CENTER DIVISION 1176 HOWELL STREET NEWPORT Rl 02841-1708 IN REPLY REFER TO: Attorney Docket No. 82649 Date: 23 September 2004 The below identified

40 & 50 Foot PS-1 Box Car Assembly Instructions

40 & 50 Foot PS-1 Box Car Instructions Push the #2100 coupler/stirrup assembly onto the ends of the metal floor. Slide them into the slots and slightly lift the ends (wings), then press firmly on the front

40 & 50 Foot PS-1 Box Car Instructions Push the #2100 coupler/stirrup assembly onto the ends of the metal floor. Slide them into the slots and slightly lift the ends (wings), then press firmly on the front

The Helicoidal or Wire Stone Saw

The Helicoidal or Wire Stone Saw From Scientific American, March 6, 1886, pp. 147-148 This article, which begins on the next page, is presented on the Stone Quarries and Beyond web site in the Quarry Equipment

The Helicoidal or Wire Stone Saw From Scientific American, March 6, 1886, pp. 147-148 This article, which begins on the next page, is presented on the Stone Quarries and Beyond web site in the Quarry Equipment

(51) Int Cl.: F16D 1/08 ( ) B21D 41/00 ( ) B62D 1/20 ( )

(19) TEPZZ 56 5A_T (11) EP 3 115 635 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 11.01.2017 Bulletin 2017/02 (21) Application number: 16177975.6 (51) Int Cl.: F16D 1/08 (2006.01) B21D

(19) TEPZZ 56 5A_T (11) EP 3 115 635 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 11.01.2017 Bulletin 2017/02 (21) Application number: 16177975.6 (51) Int Cl.: F16D 1/08 (2006.01) B21D

ADJUSTABLE CUTTING TOOL HOLDER INVENTORS WILLIAM LEE STEINHOUR Goneaway Lane Glenarm, Illinois DREW WEST

Patent Application ADJUSTABLE CUTTING TOOL HOLDER INVENTORS WILLIAM LEE STEINHOUR 111 11946 Goneaway Lane Glenarm, Illinois 62536 DREW WEST 5201 South Hutchinson Ct. Battlefield, Missouri 69619 STEVE HONEYCUTT

Patent Application ADJUSTABLE CUTTING TOOL HOLDER INVENTORS WILLIAM LEE STEINHOUR 111 11946 Goneaway Lane Glenarm, Illinois 62536 DREW WEST 5201 South Hutchinson Ct. Battlefield, Missouri 69619 STEVE HONEYCUTT

(12) United States Patent (10) Patent No.: US 6,705,355 B1

USOO670.5355B1 (12) United States Patent (10) Patent No.: US 6,705,355 B1 Wiesenfeld (45) Date of Patent: Mar. 16, 2004 (54) WIRE STRAIGHTENING AND CUT-OFF (56) References Cited MACHINE AND PROCESS NEAN

USOO670.5355B1 (12) United States Patent (10) Patent No.: US 6,705,355 B1 Wiesenfeld (45) Date of Patent: Mar. 16, 2004 (54) WIRE STRAIGHTENING AND CUT-OFF (56) References Cited MACHINE AND PROCESS NEAN

MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

XXXX B23 MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR XXXX PLANING; SLOTTING; SHEARING; BROACHING; SAWING; FILING; SCRAPING; LIKE OPERATIONS FOR WORKING METAL BY REMOVING MATERIAL, NOT OTHERWISE

XXXX B23 MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR XXXX PLANING; SLOTTING; SHEARING; BROACHING; SAWING; FILING; SCRAPING; LIKE OPERATIONS FOR WORKING METAL BY REMOVING MATERIAL, NOT OTHERWISE

United States Patent [19]

![United States Patent [19] United States Patent [19]](/thumbs/90/101999790.jpg) United States Patent [19] Landeis 111111 1111111111111111111111111111111111111111111111111111111111111 US005904033A [11] Patent Number: [45] Date of Patent: May 18, 1999 [54] VINE CUTTER [76] Inventor:

United States Patent [19] Landeis 111111 1111111111111111111111111111111111111111111111111111111111111 US005904033A [11] Patent Number: [45] Date of Patent: May 18, 1999 [54] VINE CUTTER [76] Inventor:

Nov. 14, 1967 D. PREston 3,352,553 CONTINUOUS FORMS FOLDER MACHINE

Nov. 14, 1967 D. PREston CONTINUOUS FORMS FOLDER MACHINE Filed Oct. 14, 1965 4 Sheets-Sheet Nov. 14, 1967 D. PRESTON CONTINUOUS FORMS FOLDER MACHINE Filed Oct. l4, 1965 4. Sheets-Sheet 2 t -O.S. s t ae

Nov. 14, 1967 D. PREston CONTINUOUS FORMS FOLDER MACHINE Filed Oct. 14, 1965 4 Sheets-Sheet Nov. 14, 1967 D. PRESTON CONTINUOUS FORMS FOLDER MACHINE Filed Oct. l4, 1965 4. Sheets-Sheet 2 t -O.S. s t ae

SEAT-SUPPORTED COAT HANGER FOR AUTOMOBILES [HANGING GARMENTS ON SEATS]

![SEAT-SUPPORTED COAT HANGER FOR AUTOMOBILES [HANGING GARMENTS ON SEATS] SEAT-SUPPORTED COAT HANGER FOR AUTOMOBILES [HANGING GARMENTS ON SEATS]](/thumbs/71/66113354.jpg) SEAT-SUPPORTED COAT HANGER FOR AUTOMOBILES [HANGING GARMENTS ON SEATS] CROSS-REFERENCE TO RELATED APPLICATIONS [0001] Not applicable. 5 PRIORITY CLAIM [0002] Option 1: This application claims benefit of

SEAT-SUPPORTED COAT HANGER FOR AUTOMOBILES [HANGING GARMENTS ON SEATS] CROSS-REFERENCE TO RELATED APPLICATIONS [0001] Not applicable. 5 PRIORITY CLAIM [0002] Option 1: This application claims benefit of

Z3: wa 2%ist a? 4,822. rizzesses 3.5L ES. K. N. 944,489. Patented Dec. 28, &ANN

- B, A, INDERMAN, EDCNG ATTACHMENT FOR LUMBER JOINING MACHINES, APPLICATION FILED JUNE 1, 1909. 944,489. Patented Dec. 28, 1909. 4. SHEETS-SHEET 1. E 26&ANN assa, 3.5L ES. K. N. Z3: 3. rizzesses f 2. aza

- B, A, INDERMAN, EDCNG ATTACHMENT FOR LUMBER JOINING MACHINES, APPLICATION FILED JUNE 1, 1909. 944,489. Patented Dec. 28, 1909. 4. SHEETS-SHEET 1. E 26&ANN assa, 3.5L ES. K. N. Z3: 3. rizzesses f 2. aza

Operating Instructions

Operating Instructions Holding the material against the angle gauge slide it into the forming head. Be sure that the material remains against the gauge until work is finished. NOTE: This machine will handle

Operating Instructions Holding the material against the angle gauge slide it into the forming head. Be sure that the material remains against the gauge until work is finished. NOTE: This machine will handle

52/8 04/2005 UNIVERSAL. Narrow Stitching Head. Operating-Instructions Spare parts list

Operating-Instructions Spare parts list UNIVERSAL 52/8 04/2005 Narrow Stitching Head hohner Maschinenbau GmbH Gänsäcker 19, 78532 Tuttlingen, Telephone 07462 / 9468-0, Fax 07462 / 9468-20 hohner Maschinenbau

Operating-Instructions Spare parts list UNIVERSAL 52/8 04/2005 Narrow Stitching Head hohner Maschinenbau GmbH Gänsäcker 19, 78532 Tuttlingen, Telephone 07462 / 9468-0, Fax 07462 / 9468-20 hohner Maschinenbau

Smith-Corona HOW TO USE PORTABLE TYPEWRITERS FLOATING SHIFT MODELS. L C Smith & Corona Typewriters Inc 701 E Washington St Syracuse N Y

HOW TO USE Smith-Corona PORTABLE TYPEWRITERS FLOATING SHIFT MODELS Printed and Published by L C Smith & Corona Typewriters Inc 701 E Washington St Syracuse N Y ' The serial number, stamped 0n the inner

HOW TO USE Smith-Corona PORTABLE TYPEWRITERS FLOATING SHIFT MODELS Printed and Published by L C Smith & Corona Typewriters Inc 701 E Washington St Syracuse N Y ' The serial number, stamped 0n the inner

General Wood Shop Notes

General Wood Shop Notes Restricted Materials No METAL or BONE of any kind on any machine or in the room o See additional restrictions individual machine All reclaimed and other than new lumber must be

General Wood Shop Notes Restricted Materials No METAL or BONE of any kind on any machine or in the room o See additional restrictions individual machine All reclaimed and other than new lumber must be

No. 394,668, Patented Dec. 18, 1888.